The 16 Pin Obd2 Connector is a standardized interface in vehicles that allows diagnostic tools to access the car’s computer for troubleshooting; OBD2-SCANNER.EDU.VN offers expert advice on its usage. This port enables mechanics and car owners to read trouble codes, monitor vehicle performance, and ensure proper maintenance. This technology enhances vehicle diagnostics, automotive repairs, and engine performance.

Contents

- 1. Understanding the 16 Pin OBD2 Connector: An Overview

- 1.1. What is the OBD2 Connector?

- 1.2. Why 16 Pins?

- 1.3. Location of the OBD2 Connector

- 2. Key Functions of the 16 Pin OBD2 Connector

- 2.1. Reading Diagnostic Trouble Codes (DTCs)

- 2.2. Monitoring Live Data

- 2.3. Vehicle Inspections and Smog Checks

- 3. Essential Tools and Equipment for Using the OBD2 Connector

- 3.1. OBD2 Scanners

- 3.2. Scan Tools

- 3.3. Software and Apps

- 4. Common Issues and Troubleshooting with the 16 Pin OBD2 Connector

- 4.1. Connector Damage

- 4.2. Communication Errors

- 4.3. Software and Compatibility Issues

- 5. Advanced Diagnostics with the 16 Pin OBD2 Connector

- 5.1. Bi-Directional Control

- 5.2. Module Programming and Calibration

- 5.3. Advanced Data Analysis

- 6. Communication Protocols Used by the 16 Pin OBD2 Connector

- 6.1. SAE J1850 VPW and PWM

- 6.2. ISO 9141-2 and KWP2000

- 6.3. CAN (Controller Area Network)

- 7. Ensuring Compliance and Standards with the 16 Pin OBD2 Connector

- 7.1. SAE J1962 Standard

- 7.2. ISO 15031 Standard

- 7.3. CARB Regulations

- 8. Future Trends in OBD2 Technology

- 8.1. Enhanced Security

- 8.2. Over-the-Air (OTA) Updates

- 8.3. Integration with Connected Car Services

- 9. Practical Applications of the 16 Pin OBD2 Connector

- 9.1. Diagnosing Engine Problems

- 9.2. Monitoring Fuel Efficiency

- 9.3. Ensuring Vehicle Safety

- 10. OBD2 Connector and Environmental Impact

- 10.1. Monitoring Emissions

- 10.2. Reducing Pollution

- 10.3. Promoting Sustainable Practices

- FAQ: 16 Pin OBD2 Connector

- Q1: What is an OBD2 scanner?

- Q2: How do I read OBD2 fault codes?

- Q3: What are common car problems indicated by OBD2 codes?

- Q4: Can I use any OBD2 scanner on my car?

- Q5: What is the location of the OBD2 port in my car?

- Q6: Is it safe to drive with an OBD2 fault code?

- Q7: What do the different pins in the 16 pin OBD2 connector do?

- Q8: Can I clear OBD2 codes myself?

- Q9: What does the MIL (Malfunction Indicator Lamp) mean?

- Q10: How does OBD2 technology help the environment?

1. Understanding the 16 Pin OBD2 Connector: An Overview

The 16 pin OBD2 connector serves as a crucial interface for accessing a vehicle’s onboard computer. It allows users to retrieve diagnostic information, monitor performance metrics, and ensure timely maintenance, enhancing vehicle diagnostics and promoting proactive automotive maintenance.

1.1. What is the OBD2 Connector?

The On-Board Diagnostics II (OBD2) connector is a standardized port found in most modern vehicles, mandated in the United States since 1996. According to the Environmental Protection Agency (EPA), this standardization ensures that any compliant diagnostic tool can interface with any vehicle, simplifying automotive diagnostics. This connector provides access to a wealth of data related to the vehicle’s engine, transmission, and other systems, enabling effective engine diagnostics and system monitoring.

1.2. Why 16 Pins?

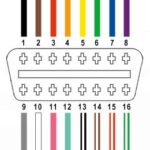

The 16 pins in the OBD2 connector are specifically designated for various functions, ensuring comprehensive communication between the vehicle’s computer and diagnostic tools. As outlined in the SAE J1962 standard, these pins facilitate power supply, ground connections, and data transfer using different communication protocols, optimizing automotive communication protocols and diagnostic data transmission. The allocation of these pins includes:

- Pin 4: Chassis Ground

- Pin 5: Signal Ground

- Pin 6: CAN High (Controller Area Network)

- Pin 7: ISO 9141-2 K-Line

- Pin 10: SAE J1850 Bus-

- Pin 14: CAN Low

- Pin 15: ISO 9141-2 L-Line

- Pin 16: Battery Power

This configuration allows for a wide range of diagnostic capabilities, supporting robust vehicle diagnostics and comprehensive system analysis.

1.3. Location of the OBD2 Connector

The OBD2 connector is typically located within reach of the driver’s seat, often under the dashboard. According to vehicle manufacturer guidelines, common locations include:

- Under the dashboard on the driver’s side

- Near the steering column

- Inside the center console

This standardized placement ensures easy access for technicians and vehicle owners, facilitating efficient diagnostic port accessibility and streamlined vehicle maintenance.

2. Key Functions of the 16 Pin OBD2 Connector

The 16 pin OBD2 connector supports numerous functions that are vital for vehicle diagnostics and maintenance. Its primary capabilities include reading diagnostic trouble codes (DTCs), monitoring live data, and performing vehicle inspections.

2.1. Reading Diagnostic Trouble Codes (DTCs)

One of the most critical functions of the OBD2 connector is its ability to read diagnostic trouble codes (DTCs). These codes are generated when the vehicle’s computer detects a problem with any of its systems. According to the National Institute for Automotive Service Excellence (ASE), understanding these codes is the first step in diagnosing and repairing vehicle issues. Common DTC categories include:

- P (Powertrain Codes): Relate to the engine, transmission, and fuel system.

- B (Body Codes): Pertain to components like airbags, power windows, and seats.

- C (Chassis Codes): Involve systems such as ABS (Anti-lock Braking System) and traction control.

- U (Network Codes): Indicate communication issues between different control modules.

By reading these codes, technicians can quickly identify the source of the problem and take appropriate action, enabling accurate fault code identification and effective automotive troubleshooting.

2.2. Monitoring Live Data

The OBD2 connector also allows for real-time monitoring of various vehicle parameters. This live data can provide valuable insights into the vehicle’s performance and help diagnose intermittent issues. Common data parameters include:

- Engine Speed (RPM): Indicates how fast the engine is running.

- Vehicle Speed: Shows the current speed of the vehicle.

- Coolant Temperature: Monitors the engine’s cooling system.

- Oxygen Sensor Readings: Measures the oxygen content in the exhaust gases.

- Fuel Trim: Indicates adjustments made to the fuel delivery system.

According to a study by the Society of Automotive Engineers (SAE), monitoring live data can significantly reduce diagnostic time and improve accuracy. This capability supports real-time vehicle monitoring and enhanced diagnostic accuracy.

2.3. Vehicle Inspections and Smog Checks

Many states require vehicles to undergo regular inspections to ensure they meet emissions standards. The OBD2 connector plays a crucial role in these inspections by allowing technicians to quickly assess the vehicle’s emissions readiness. The OBD2 system monitors various emissions-related components and systems, and it sets readiness flags to indicate whether these systems have been tested. Technicians can use an OBD2 scanner to check these flags and determine if the vehicle is ready for a smog check. This functionality streamlines vehicle inspection processes and ensures emissions compliance.

3. Essential Tools and Equipment for Using the OBD2 Connector

To effectively use the 16 pin OBD2 connector, technicians and vehicle owners need the right tools and equipment. Key tools include OBD2 scanners, scan tools, and specialized software.

3.1. OBD2 Scanners

OBD2 scanners are handheld devices used to read diagnostic trouble codes and monitor live data. According to a report by Consumer Reports, a good OBD2 scanner should be user-friendly, accurate, and compatible with a wide range of vehicles. Features to look for in an OBD2 scanner include:

- Code Definitions: Provides clear explanations of diagnostic trouble codes.

- Live Data Streaming: Allows real-time monitoring of vehicle parameters.

- Data Logging: Records data for later analysis.

- Connectivity: Offers options for connecting to a computer or smartphone.

These features enhance diagnostic capabilities and provide comprehensive vehicle data access.

3.2. Scan Tools

Scan tools are more advanced diagnostic devices that offer additional capabilities beyond basic code reading. These tools often include features such as:

- Bi-Directional Control: Allows technicians to command the vehicle’s computer to perform specific actions.

- Advanced Diagnostics: Provides access to manufacturer-specific diagnostic codes and data.

- Programming and Calibration: Enables technicians to reprogram control modules and calibrate sensors.

According to a study by Automotive Engineering International, scan tools can significantly improve diagnostic accuracy and reduce repair times. These tools offer advanced control and diagnostic functionalities.

3.3. Software and Apps

In addition to hardware tools, various software applications and mobile apps can enhance the functionality of the OBD2 connector. These apps can turn a smartphone or tablet into a powerful diagnostic tool. Popular OBD2 apps include:

- Torque Pro: Offers real-time monitoring of vehicle parameters and customizable dashboards.

- OBD Auto Doctor: Provides comprehensive diagnostic information and code definitions.

- FORScan: Specialized for Ford, Lincoln, and Mercury vehicles, offering advanced diagnostic and programming capabilities.

These software solutions provide enhanced vehicle data analysis and customization.

4. Common Issues and Troubleshooting with the 16 Pin OBD2 Connector

While the OBD2 connector is a reliable interface, it can sometimes encounter issues. Common problems include connector damage, communication errors, and software compatibility issues.

4.1. Connector Damage

The OBD2 connector can be damaged due to physical wear and tear, corrosion, or improper use. Signs of a damaged connector include:

- Bent or Broken Pins: Can prevent proper communication between the scanner and the vehicle’s computer.

- Corrosion: Can cause intermittent connectivity issues.

- Loose Connection: Can result in unreliable data transmission.

According to a technical service bulletin from Bosch, regular inspection and maintenance of the OBD2 connector can prevent many of these issues. Addressing these issues ensures reliable connectivity and accurate data transmission.

4.2. Communication Errors

Communication errors can occur when the OBD2 scanner is unable to establish a connection with the vehicle’s computer. Common causes of communication errors include:

- Incorrect Protocol: The scanner may not be using the correct communication protocol for the vehicle.

- Faulty Wiring: Problems with the vehicle’s wiring can prevent communication.

- ECU Issues: The vehicle’s engine control unit (ECU) may be malfunctioning.

Troubleshooting communication errors often involves verifying the scanner’s compatibility, checking the vehicle’s wiring, and testing the ECU. Resolving these errors ensures successful vehicle communication and diagnostics.

4.3. Software and Compatibility Issues

Software and compatibility issues can arise when the OBD2 scanner or app is not compatible with the vehicle’s make and model. Symptoms of these issues include:

- Inaccurate Data: The scanner may display incorrect or incomplete data.

- Software Crashes: The app may crash or freeze during use.

- Limited Functionality: The scanner may not support all of the vehicle’s diagnostic functions.

Ensuring that the OBD2 scanner and software are compatible with the vehicle is essential for accurate and reliable diagnostics. Compatibility ensures accurate data and comprehensive functionality.

5. Advanced Diagnostics with the 16 Pin OBD2 Connector

Beyond basic code reading and data monitoring, the 16 pin OBD2 connector supports advanced diagnostic techniques that can help technicians diagnose complex vehicle issues. These techniques include bi-directional control, module programming, and advanced data analysis.

5.1. Bi-Directional Control

Bi-directional control allows technicians to send commands to the vehicle’s computer and observe the response. This capability can be used to test various components and systems, such as:

- Activating Solenoids: Testing the operation of solenoids in the transmission or fuel system.

- Cycling Relays: Verifying the functionality of relays in the electrical system.

- Performing Injector Kill Tests: Identifying faulty fuel injectors.

According to a study by the American Society for Quality (ASQ), bi-directional control can significantly improve diagnostic accuracy and reduce the need for guesswork. This advanced control enhances diagnostic accuracy and efficiency.

5.2. Module Programming and Calibration

Module programming and calibration involve reprogramming or updating the software in the vehicle’s control modules. This process is often necessary after replacing a module or to address software bugs. Common programming and calibration tasks include:

- ECU Reprogramming: Updating the engine control unit’s software.

- TCM Calibration: Calibrating the transmission control module.

- ABS Module Programming: Programming the anti-lock braking system module.

Module programming requires specialized tools and software, as well as a thorough understanding of the vehicle’s systems. Proper programming ensures optimal performance and reliability.

5.3. Advanced Data Analysis

Advanced data analysis involves using sophisticated tools and techniques to interpret the data obtained from the OBD2 connector. This can include:

- Waveform Analysis: Analyzing the signals from sensors and actuators to identify anomalies.

- Statistical Analysis: Using statistical methods to identify trends and patterns in the data.

- Customized Reports: Generating detailed reports that summarize the diagnostic findings.

According to a report by McKinsey & Company, advanced data analytics is becoming increasingly important in the automotive industry, enabling more effective diagnostics and predictive maintenance. This analysis facilitates effective diagnostics and predictive maintenance.

6. Communication Protocols Used by the 16 Pin OBD2 Connector

The 16 pin OBD2 connector supports several communication protocols that define how data is transmitted between the vehicle’s computer and the diagnostic tool. Understanding these protocols is essential for effective diagnostics.

6.1. SAE J1850 VPW and PWM

SAE J1850 VPW (Variable Pulse Width) and PWM (Pulse Width Modulation) are older communication protocols used primarily in General Motors (GM) and Ford vehicles. These protocols use a single wire for data transmission and rely on variations in pulse width to encode the data. Key characteristics of J1850 VPW and PWM include:

- VPW: Used by GM vehicles, operates at 10.4 kbps.

- PWM: Used by Ford vehicles, operates at 41.6 kbps.

While these protocols are less common in newer vehicles, they are still used in some older models.

6.2. ISO 9141-2 and KWP2000

ISO 9141-2 and KWP2000 (Keyword Protocol 2000) are communication protocols used by many European and Asian vehicles. These protocols use two wires, known as the K-line and L-line, for data transmission. Key characteristics of ISO 9141-2 and KWP2000 include:

- ISO 9141-2: Operates at 9.6 kbps and uses a start bit, data bits, and a stop bit for data transmission.

- KWP2000: An evolution of ISO 9141-2, offering faster data rates and more advanced features.

These protocols provide reliable data transmission for a variety of vehicle systems.

6.3. CAN (Controller Area Network)

CAN (Controller Area Network) is the most modern and widely used communication protocol in OBD2 systems. It is used by virtually all new vehicles and offers significant advantages over older protocols, including:

- High Speed: Supports data rates up to 1 Mbps.

- Robustness: Provides reliable communication even in noisy environments.

- Flexibility: Allows multiple control modules to communicate with each other.

According to a technical paper by Robert Bosch GmbH, CAN is the backbone of modern automotive communication networks, enabling advanced features such as electronic stability control and adaptive cruise control. This modern protocol enables advanced vehicle features and reliable communication.

7. Ensuring Compliance and Standards with the 16 Pin OBD2 Connector

Compliance with industry standards is crucial for ensuring the reliability and compatibility of OBD2 systems. Key standards include SAE J1962, ISO 15031, and CARB regulations.

7.1. SAE J1962 Standard

SAE J1962 defines the physical characteristics of the OBD2 connector, including the pinout, dimensions, and electrical specifications. Compliance with this standard ensures that all OBD2-compliant devices can physically connect to the vehicle’s diagnostic port. Key aspects of the SAE J1962 standard include:

- Connector Shape and Size: Specifies the physical dimensions of the connector to ensure a secure fit.

- Pin Assignments: Defines the function of each pin in the connector.

- Electrical Specifications: Sets limits for voltage, current, and impedance.

Adhering to this standard ensures physical compatibility and reliable connections.

7.2. ISO 15031 Standard

ISO 15031 defines the communication protocols and diagnostic services used in OBD2 systems. Compliance with this standard ensures that diagnostic tools can communicate with the vehicle’s computer in a standardized manner. Key aspects of the ISO 15031 standard include:

- Diagnostic Trouble Codes (DTCs): Defines the format and meaning of DTCs.

- Data Parameters (PIDs): Specifies the format and units of measurement for live data parameters.

- Diagnostic Services: Defines the commands and responses used for diagnostic communication.

This standard ensures standardized communication and diagnostic services.

7.3. CARB Regulations

The California Air Resources Board (CARB) has played a leading role in the development and implementation of OBD2 standards. CARB regulations require all vehicles sold in California to comply with specific OBD2 requirements. Key aspects of CARB regulations include:

- Emissions Monitoring: Requires vehicles to monitor various emissions-related components and systems.

- Readiness Flags: Sets requirements for the readiness flags that indicate whether these systems have been tested.

- Reporting Requirements: Mandates that vehicle manufacturers provide detailed diagnostic information to technicians and consumers.

Compliance with CARB regulations ensures emissions monitoring and diagnostic transparency.

8. Future Trends in OBD2 Technology

OBD2 technology continues to evolve, with new features and capabilities being added to address the changing needs of the automotive industry. Key trends include enhanced security, over-the-air updates, and integration with connected car services.

8.1. Enhanced Security

As vehicles become more connected, security is becoming an increasingly important concern. Modern OBD2 systems incorporate security features to protect against unauthorized access and tampering. These features include:

- Encryption: Encrypting the data transmitted between the vehicle’s computer and the diagnostic tool.

- Authentication: Requiring the diagnostic tool to authenticate itself before accessing sensitive data.

- Intrusion Detection: Monitoring the OBD2 port for suspicious activity and alerting the vehicle owner or technician.

According to a report by the National Highway Traffic Safety Administration (NHTSA), enhanced security measures are essential for protecting vehicles against cyberattacks. These measures protect against unauthorized access and cyber threats.

8.2. Over-the-Air (OTA) Updates

Over-the-air (OTA) updates allow vehicle manufacturers to update the software in the vehicle’s control modules remotely. This can be used to fix bugs, improve performance, and add new features. Key benefits of OTA updates include:

- Convenience: Eliminates the need to visit a dealership for software updates.

- Timeliness: Allows manufacturers to quickly address issues and deploy updates.

- Cost Savings: Reduces the cost of software updates for both manufacturers and consumers.

OTA updates provide convenient and timely software improvements.

8.3. Integration with Connected Car Services

OBD2 technology is increasingly being integrated with connected car services, such as:

- Remote Diagnostics: Allows vehicle owners to remotely monitor the health of their vehicle and receive alerts when problems are detected.

- Usage-Based Insurance: Tracks driving behavior and provides personalized insurance rates.

- Stolen Vehicle Recovery: Helps law enforcement locate and recover stolen vehicles.

According to a report by Statista, the market for connected car services is expected to grow rapidly in the coming years, driven by the increasing demand for convenience, safety, and security. This integration enhances convenience, safety, and security for vehicle owners.

9. Practical Applications of the 16 Pin OBD2 Connector

The 16 pin OBD2 connector has a wide range of practical applications for both automotive technicians and vehicle owners. These applications include diagnosing engine problems, monitoring fuel efficiency, and ensuring vehicle safety.

9.1. Diagnosing Engine Problems

One of the most common uses of the OBD2 connector is to diagnose engine problems. By reading diagnostic trouble codes and monitoring live data, technicians can quickly identify the source of the problem and take appropriate action. Common engine problems that can be diagnosed using the OBD2 connector include:

- Misfires: Indicates that one or more cylinders are not firing properly.

- Oxygen Sensor Failures: Can cause poor fuel economy and emissions problems.

- Catalytic Converter Issues: Can result in high emissions and reduced engine performance.

The OBD2 connector enables quick and accurate engine problem diagnosis.

9.2. Monitoring Fuel Efficiency

The OBD2 connector can also be used to monitor fuel efficiency. By tracking parameters such as fuel consumption, engine load, and vehicle speed, vehicle owners can identify ways to improve their fuel economy. Common strategies for improving fuel efficiency include:

- Reducing Idling: Minimizing the amount of time spent idling can save fuel.

- Driving at Optimal Speeds: Driving at moderate speeds can improve fuel economy.

- Maintaining Proper Tire Inflation: Properly inflated tires reduce rolling resistance and improve fuel efficiency.

Monitoring these parameters can help optimize fuel consumption and reduce costs.

9.3. Ensuring Vehicle Safety

The OBD2 connector can also be used to ensure vehicle safety. By monitoring systems such as ABS, airbags, and traction control, technicians can identify potential safety issues and take corrective action. Common safety-related problems that can be diagnosed using the OBD2 connector include:

- ABS Failures: Can compromise the vehicle’s braking performance.

- Airbag Malfunctions: Can prevent the airbags from deploying in a crash.

- Traction Control Issues: Can reduce the vehicle’s stability in slippery conditions.

This functionality ensures vehicle safety and prevents potential hazards.

10. OBD2 Connector and Environmental Impact

The 16 pin OBD2 connector plays a significant role in reducing the environmental impact of vehicles by helping to ensure that they meet emissions standards. By monitoring emissions-related components and systems, the OBD2 system can detect problems that could lead to increased pollution.

10.1. Monitoring Emissions

The OBD2 system monitors various emissions-related components and systems, such as:

- Oxygen Sensors: Measure the oxygen content in the exhaust gases.

- Catalytic Converter: Reduces harmful emissions.

- Evaporative Emissions Control System (EVAP): Prevents fuel vapors from escaping into the atmosphere.

By detecting problems with these systems, the OBD2 system can help vehicle owners and technicians take corrective action, reducing emissions and protecting the environment.

10.2. Reducing Pollution

By ensuring that vehicles meet emissions standards, the OBD2 system helps to reduce pollution. According to the EPA, OBD2 systems have played a significant role in reducing air pollution from vehicles since their introduction in the 1990s. Key benefits of OBD2 systems in reducing pollution include:

- Early Detection of Problems: Allows for early detection and correction of emissions-related problems.

- Improved Fuel Economy: Helps to improve fuel economy, reducing the amount of fuel consumed and emissions produced.

- Compliance with Regulations: Ensures that vehicles comply with emissions regulations, helping to protect the environment.

These benefits contribute to cleaner air and a healthier environment.

10.3. Promoting Sustainable Practices

The use of OBD2 technology promotes sustainable practices in the automotive industry by encouraging vehicle owners and technicians to maintain their vehicles properly. Regular maintenance can help to improve fuel economy, reduce emissions, and extend the life of the vehicle, all of which contribute to a more sustainable transportation system.

OBD2-SCANNER.EDU.VN is committed to providing expert guidance and support for using OBD2 technology to diagnose and repair your vehicle. Our team of experienced technicians can help you understand the data provided by your OBD2 scanner and develop a plan to address any issues you may be experiencing. Contact us today at 123 Main Street, Los Angeles, CA 90001, United States, or call us at +1 (641) 206-8880. You can also visit our website at OBD2-SCANNER.EDU.VN for more information. Let us help you keep your vehicle running smoothly and efficiently.

FAQ: 16 Pin OBD2 Connector

Q1: What is an OBD2 scanner?

An OBD2 scanner is a device used to read diagnostic trouble codes (DTCs) from a vehicle’s onboard computer via the 16 pin OBD2 connector, aiding in vehicle diagnostics. These codes help identify potential issues with the engine, transmission, and other systems.

Q2: How do I read OBD2 fault codes?

To read OBD2 fault codes, plug an OBD2 scanner into the 16 pin OBD2 connector, turn on the ignition, and follow the scanner’s prompts to retrieve the codes. Refer to the scanner’s manual for specific instructions.

Q3: What are common car problems indicated by OBD2 codes?

Common car problems indicated by OBD2 codes include engine misfires, oxygen sensor failures, catalytic converter issues, and problems with the evaporative emissions control system (EVAP), all accessible via the 16 pin OBD2 connector.

Q4: Can I use any OBD2 scanner on my car?

While OBD2 scanners are standardized, compatibility can vary. Ensure the scanner supports your vehicle’s communication protocol (e.g., CAN, ISO, J1850) to effectively interface with the 16 pin OBD2 connector.

Q5: What is the location of the OBD2 port in my car?

The OBD2 port is typically located under the dashboard on the driver’s side, near the steering column or in the center console, ensuring easy access to the 16 pin OBD2 connector.

Q6: Is it safe to drive with an OBD2 fault code?

It depends on the nature of the fault. Some codes indicate minor issues, while others may signal severe problems. Consult a mechanic or use a reliable source to interpret the code and determine if it’s safe to drive using the 16 pin OBD2 connector information.

Q7: What do the different pins in the 16 pin OBD2 connector do?

The 16 pins in the OBD2 connector are designated for various functions, including power supply, ground connections, and data transfer using different communication protocols, as outlined in the SAE J1962 standard.

Q8: Can I clear OBD2 codes myself?

Yes, you can clear OBD2 codes using an OBD2 scanner, but it’s important to understand the underlying issue first. Clearing codes without fixing the problem may cause it to return, potentially leading to further damage, all diagnosed through the 16 pin OBD2 connector.

Q9: What does the MIL (Malfunction Indicator Lamp) mean?

The MIL, often called the “check engine” light, illuminates when the OBD2 system detects a problem. It indicates that a diagnostic trouble code has been stored and can be accessed via the 16 pin OBD2 connector.

Q10: How does OBD2 technology help the environment?

OBD2 technology helps the environment by monitoring emissions-related components and systems, ensuring vehicles meet emissions standards and reducing pollution. This monitoring is facilitated through the 16 pin OBD2 connector.

Is your check engine light on? Unsure of how to interpret the data from your OBD2 scanner? Contact OBD2-SCANNER.EDU.VN today for expert assistance and reliable repair services. Reach us at 123 Main Street, Los Angeles, CA 90001, United States, call +1 (641) 206-8880, or visit our website OBD2-SCANNER.EDU.VN for a consultation. Let us help you diagnose and resolve your vehicle’s issues efficiently.