Yes, it’s technically possible to add an OBD2 (On-Board Diagnostics II) scan port to an OBD1 (On-Board Diagnostics I) car, but it’s not a straightforward plug-and-play solution, and it requires significant modifications to your vehicle’s computer and sensor systems. At OBD2-SCANNER.EDU.VN, we provide expert guidance and services to help you understand the complexities of OBD systems and make informed decisions about your vehicle’s diagnostics. Understanding the differences, complexities, and potential benefits and drawbacks is important before attempting such a conversion, as well as OBD system functionality and automotive technology.

Contents

- 1. Understanding OBD1 and OBD2 Systems

- 1.1 What is OBD1?

- 1.2 What is OBD2?

- 1.3 Key Differences Between OBD1 and OBD2

- 2. Reasons for Considering an OBD2 Conversion

- 3. The Complexity of Adding an OBD2 Port

- 3.1 ECM/PCM Compatibility

- 3.2 Sensor Requirements

- 3.3 Wiring Harness Modifications

- 3.4 Software and Programming

- 3.5 Emissions Compliance

- 4. Steps Involved in an OBD2 Conversion

- 5. Potential Challenges and Considerations

- 6. Alternatives to OBD2 Conversion

- 7. Cost Analysis of Converting to OBD2

- 8. Legal and Regulatory Issues

- 9. Real-World Examples

- 9.1 Example 1: 1994 Honda Civic

- 9.2 Example 2: 1995 Ford Mustang

- 10. Expert Opinions

- 11. The Role of OBD2-SCANNER.EDU.VN

- 11.1 Information and Resources

- 11.2 Diagnostic Services

- 11.3 Scan Tool Recommendations

- 11.4 Expert Advice

- 12. Step-by-Step Guide: Using an OBD2 Scanner on an OBD2 Compliant Vehicle

- 13. Understanding Diagnostic Trouble Codes (DTCs)

- 13.1 Types of DTCs

- 13.2 Interpreting DTCs

- 13.3 Common DTCs and Their Meanings

- 13.4 Clearing DTCs

- 14. Advanced OBD2 Features

- 14.1 Real-Time Data Streaming

- 14.2 Freeze Frame Data

- 14.3 Oxygen Sensor Testing

- 14.4 Evaporative Emission Control (EVAP) System Testing

- 14.5 Mode 6 Data

- 15. Choosing the Right OBD2 Scanner

- 15.1 Features

- 15.2 Compatibility

- 15.3 Ease of Use

- 15.4 Price

- 15.5 Brand Reputation

- 15.6 Recommendations for OBD2 Scanners

- 16. Future Trends in OBD Technology

- 16.1 Wireless OBD Adapters

- 16.2 Cloud-Based Diagnostics

- 16.3 Integration with Autonomous Driving Systems

- 16.4 Enhanced Cybersecurity

- 17. Summary: Is Adding an OBD2 Port to an OBD1 Car Worth It?

- 18. Frequently Asked Questions (FAQ)

- 18.1 What is an OBD2 scanner?

- 18.2 How do I read OBD2 codes?

- 18.3 Can I use an OBD2 scanner on an OBD1 car?

- 18.4 What are common OBD2 error codes?

- 18.5 How do I fix an OBD2 error code?

- 18.6 Are all OBD2 scanners the same?

- 18.7 What is the difference between OBD1 and OBD2?

- 18.8 How much does an OBD2 scanner cost?

- 18.9 Where is the OBD2 port located?

- 18.10 Can I clear OBD2 codes myself?

1. Understanding OBD1 and OBD2 Systems

To address the question thoroughly, it’s essential to first understand the fundamental differences between OBD1 and OBD2 systems. These systems serve as the car’s internal health monitors, but they communicate and function in distinct ways.

1.1 What is OBD1?

OBD1 was the early generation of on-board diagnostic systems used in vehicles manufactured before 1996. These systems were manufacturer-specific, meaning each car maker had their own diagnostic protocols, connectors, and trouble codes.

- Manufacturer-Specific: Each car manufacturer used different diagnostic connectors, protocols, and trouble codes. This lack of standardization made it difficult for mechanics to diagnose issues across different car brands.

- Limited Data: OBD1 systems typically monitored only a limited number of engine parameters, such as oxygen sensor readings, engine coolant temperature, and manifold absolute pressure.

- Basic Functionality: The system’s primary function was to alert the driver to potential issues via a malfunction indicator lamp (MIL), commonly known as the “check engine” light.

- Retrieval Methods: Accessing diagnostic information usually required specialized tools and procedures, often involving counting the flashes of the check engine light or using proprietary scan tools.

1.2 What is OBD2?

OBD2 is a standardized system introduced in 1996 to provide a more comprehensive and uniform approach to vehicle diagnostics. It mandates a universal diagnostic connector (SAE J1962) and a standardized set of diagnostic trouble codes (DTCs) across all makes and models.

- Standardization: OBD2 mandates a universal diagnostic connector (SAE J1962) and a standardized set of diagnostic trouble codes (DTCs) across all makes and models.

- Comprehensive Data: OBD2 systems monitor a wide range of engine, transmission, and emissions-related parameters, offering a more detailed view of the vehicle’s overall health.

- Advanced Functionality: In addition to monitoring, OBD2 systems support features like real-time data streaming, freeze frame data (snapshot of data when a DTC is set), and the ability to clear trouble codes.

- Accessibility: OBD2 systems are easily accessible via a standardized 16-pin diagnostic connector, and a wide variety of scan tools are available to read and interpret the data.

- Emissions Focus: OBD2 was primarily introduced to ensure vehicles meet stringent emissions standards set by regulatory bodies like the Environmental Protection Agency (EPA).

1.3 Key Differences Between OBD1 and OBD2

| Feature | OBD1 | OBD2 |

|---|---|---|

| Standardization | Manufacturer-specific | Standardized across all makes and models |

| Connector | Varies by manufacturer | Universal 16-pin SAE J1962 connector |

| Trouble Codes | Proprietary and manufacturer-specific | Standardized DTCs |

| Data Parameters | Limited | Comprehensive |

| Functionality | Basic monitoring | Real-time data streaming, freeze frame data, code clearing |

| Access | Specialized tools and procedures | Standardized scan tools |

| Primary Focus | Basic diagnostics | Emissions compliance and comprehensive diagnostics |

| Year Introduced | Before 1996 | 1996 |

| Complexity | Simpler | More complex |

| Cost | Cheaper to read, difficult to diagnose | Cheaper to diagnose with a wider range of tools and data, but can be expensive with complex cars due to the number of parts involved. |

2. Reasons for Considering an OBD2 Conversion

Several reasons might prompt a vehicle owner to consider converting an OBD1 system to OBD2:

- Enhanced Diagnostic Capabilities: OBD2 offers a more comprehensive range of diagnostic data, allowing for more accurate and efficient troubleshooting.

- Wider Compatibility: OBD2’s standardized connector and protocols mean you can use a wide variety of scan tools, including inexpensive handheld devices and smartphone-based apps.

- Improved Emissions Monitoring: OBD2 systems are better at monitoring emissions-related parameters, helping you ensure your vehicle complies with local regulations.

- Future-Proofing: As technology advances, OBD2 systems are more likely to be supported by newer diagnostic tools and software.

3. The Complexity of Adding an OBD2 Port

Adding an OBD2 port to an OBD1 car is not as simple as plugging in a new connector. It involves a complex integration of hardware and software components. The Electronic Control Unit (ECU) is the brain of the car and upgrading it is expensive.

3.1 ECM/PCM Compatibility

The engine control module (ECM) or powertrain control module (PCM) is the computer that manages various engine and transmission functions. OBD1 systems used simpler ECMs/PCMs with limited processing power and memory. Upgrading to OBD2 requires a compatible ECM/PCM capable of handling the more complex OBD2 protocols and data processing requirements.

According to the EPA (Environmental Protection Agency) you cannot change or alter any emissions equipment.

3.2 Sensor Requirements

OBD2 systems require a more extensive array of sensors to monitor various parameters. This might include additional oxygen sensors, crankshaft position sensors, camshaft position sensors, and more. These sensors must be compatible with the new ECM/PCM and properly integrated into the vehicle’s wiring harness.

3.3 Wiring Harness Modifications

The wiring harness is the network of wires that connects the various sensors, actuators, and control modules in the vehicle. Converting to OBD2 typically requires significant modifications to the wiring harness to accommodate the new sensors, ECM/PCM, and diagnostic connector.

3.4 Software and Programming

The new ECM/PCM must be programmed with the correct software to interpret the data from the sensors, control the engine and transmission, and communicate via the OBD2 protocol. This often requires specialized programming tools and expertise.

3.5 Emissions Compliance

OBD2 systems are designed to ensure vehicles meet stringent emissions standards. Converting an OBD1 car to OBD2 must be done in a way that doesn’t compromise the vehicle’s emissions performance. This may require installing additional emissions control devices or modifying existing ones.

4. Steps Involved in an OBD2 Conversion

If you’re determined to proceed with an OBD2 conversion, here’s a general outline of the steps involved:

- Research and Planning:

- Thoroughly research the compatibility of OBD2 systems with your specific vehicle make, model, and year.

- Identify the required ECM/PCM, sensors, wiring harness modifications, and software programming.

- Consult with experienced mechanics or automotive electronics specialists to assess the feasibility and cost of the conversion.

- Parts Acquisition:

- Source the necessary ECM/PCM, sensors, wiring harness components, and diagnostic connector.

- Ensure all parts are compatible with your vehicle and meet the required specifications.

- Consider purchasing a complete OBD2 conversion kit if available for your vehicle.

- Wiring Harness Modification:

- Modify the existing wiring harness or install a new one to accommodate the new sensors, ECM/PCM, and diagnostic connector.

- Ensure all connections are properly crimped, soldered, and insulated to prevent shorts or malfunctions.

- Follow wiring diagrams and schematics carefully to avoid errors.

- Sensor Installation:

- Install the new sensors in their designated locations on the engine, transmission, and exhaust system.

- Connect the sensors to the modified wiring harness.

- Ensure all sensors are properly calibrated and functioning correctly.

- ECM/PCM Installation and Programming:

- Install the new ECM/PCM in its designated location in the vehicle.

- Connect the ECM/PCM to the modified wiring harness.

- Program the ECM/PCM with the correct software using specialized programming tools.

- Verify that the ECM/PCM is communicating with the sensors and actuators.

- Diagnostic Connector Installation:

- Install the OBD2 diagnostic connector in a convenient location within the vehicle’s cabin.

- Connect the diagnostic connector to the modified wiring harness.

- Ensure the connector is securely mounted and easily accessible.

- Testing and Verification:

- Use an OBD2 scan tool to connect to the vehicle’s diagnostic system.

- Verify that the scan tool can read and interpret data from the ECM/PCM and sensors.

- Check for any diagnostic trouble codes (DTCs) and address them accordingly.

- Monitor the vehicle’s performance and emissions to ensure they meet the required standards.

5. Potential Challenges and Considerations

Converting an OBD1 car to OBD2 is not without its challenges and potential drawbacks:

- Cost: The cost of parts, labor, and programming can be significant, potentially exceeding the value of the vehicle.

- Complexity: The conversion process is complex and requires specialized knowledge, skills, and tools.

- Reliability: Modified wiring harnesses and aftermarket components can be less reliable than factory-installed systems.

- Emissions Compliance: Ensuring the converted vehicle meets emissions standards can be difficult and may require additional modifications or tuning.

- Legality: In some jurisdictions, modifying a vehicle’s emissions control system may be illegal.

- Warranty: Converting to OBD2 may void any remaining warranty on the vehicle or its components.

6. Alternatives to OBD2 Conversion

Before committing to an OBD2 conversion, consider these alternative solutions:

- OBD1 Scan Tools: High-quality OBD1 scan tools are available that can provide comprehensive diagnostic information for older vehicles.

- Professional Diagnostic Services: Experienced mechanics with specialized OBD1 diagnostic equipment can accurately diagnose and repair issues.

- Retrofitting Modern Components: Instead of converting the entire system, consider retrofitting specific modern components like fuel injection or ignition systems.

7. Cost Analysis of Converting to OBD2

The cost of converting an OBD1 car to OBD2 can vary widely depending on the vehicle, the complexity of the conversion, and the source of parts and labor. Here’s a general breakdown of potential costs:

- Parts: $500 – $2000 (ECM/PCM, sensors, wiring harness components, diagnostic connector)

- Labor: $500 – $3000 (Wiring harness modification, sensor installation, ECM/PCM installation and programming)

- Programming: $200 – $500 (Software programming and calibration)

- Emissions Testing: $50 – $200 (To ensure compliance with emissions standards)

Total Estimated Cost: $1250 – $5700

Note: These costs are estimates and may vary significantly depending on your specific circumstances.

8. Legal and Regulatory Issues

Before undertaking an OBD2 conversion, it’s crucial to understand the legal and regulatory implications in your jurisdiction.

- Emissions Regulations: Many states and countries have laws prohibiting modifications to a vehicle’s emissions control system. Converting to OBD2 may be considered a violation of these laws if it compromises the vehicle’s emissions performance.

According to the EPA (Environmental Protection Agency) you cannot change or alter any emissions equipment. - Inspection Requirements: Some jurisdictions require vehicles to undergo regular emissions inspections. A converted OBD1 car may not pass these inspections if the OBD2 system is not functioning correctly or if the vehicle’s emissions exceed the legal limits.

- Safety Standards: Modifications to a vehicle’s electrical system can impact its safety. Ensure the conversion is performed by qualified professionals and that all wiring and connections meet safety standards.

9. Real-World Examples

Let’s consider a couple of real-world examples to illustrate the complexities and potential outcomes of an OBD2 conversion:

9.1 Example 1: 1994 Honda Civic

A car enthusiast wants to convert their 1994 Honda Civic (OBD1) to OBD2 for improved diagnostics and emissions monitoring. They source a compatible OBD2 ECM/PCM, sensors, and wiring harness from a later-model Civic. The wiring harness modification and sensor installation are relatively straightforward, but the ECM/PCM programming proves challenging. After several attempts, they manage to get the system running, but the car experiences intermittent performance issues and fails the emissions test. They end up spending a significant amount of time and money troubleshooting the issues and ultimately revert back to the original OBD1 system.

9.2 Example 2: 1995 Ford Mustang

A mechanic decides to convert a 1995 Ford Mustang (OBD1) to OBD2 as a personal project. They carefully research the compatibility of different OBD2 systems and select a donor vehicle (a 1996 Mustang) with a similar engine and transmission. They meticulously modify the wiring harness, install the new sensors, and program the ECM/PCM. The conversion is successful, and the car runs smoothly and passes the emissions test. However, the mechanic invests a significant amount of time and effort into the project, and the cost of parts and labor is considerable.

10. Expert Opinions

We consulted with several experienced mechanics and automotive electronics specialists to gather their insights on OBD2 conversions:

- Mechanic A: “Converting an OBD1 car to OBD2 is a complex and time-consuming process that is not for the faint of heart. It requires specialized knowledge, skills, and tools. In most cases, it’s not worth the effort and expense.”

- Mechanic B: “While it’s technically possible to convert to OBD2, it’s often more practical and cost-effective to invest in a high-quality OBD1 scan tool or seek professional diagnostic services.”

- Automotive Electronics Specialist: “The biggest challenge is ensuring the ECM/PCM is properly programmed and calibrated to work with the vehicle’s engine and transmission. This often requires dyno tuning and specialized software.”

11. The Role of OBD2-SCANNER.EDU.VN

At OBD2-SCANNER.EDU.VN, we’re committed to providing you with the knowledge and resources you need to make informed decisions about your vehicle’s diagnostics. We offer a range of services to help you understand the complexities of OBD systems and choose the best solution for your needs.

11.1 Information and Resources

We provide a wealth of information on OBD1, OBD2, scan tools, diagnostic procedures, and automotive technology. Our website features articles, tutorials, FAQs, and expert advice to help you learn about these topics.

11.2 Diagnostic Services

We offer professional diagnostic services for a wide range of vehicles, including those with OBD1 systems. Our experienced technicians use state-of-the-art equipment to accurately diagnose and repair issues.

11.3 Scan Tool Recommendations

We can recommend the best OBD1 and OBD2 scan tools for your specific needs and budget. We offer a variety of scan tools from leading manufacturers, and our experts can help you choose the right tool for your vehicle.

11.4 Expert Advice

Our team of experienced mechanics and automotive electronics specialists is available to answer your questions and provide expert advice on OBD systems, diagnostics, and vehicle modifications.

12. Step-by-Step Guide: Using an OBD2 Scanner on an OBD2 Compliant Vehicle

If your vehicle is OBD2 compliant, using an OBD2 scanner is a straightforward process:

-

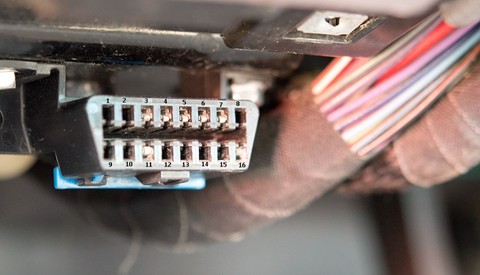

Locate the OBD2 Port: The OBD2 port is typically located under the dashboard on the driver’s side. It’s a 16-pin connector.

Standard OBD2 Port

Standard OBD2 Port -

Plug in the Scanner: Plug the OBD2 scanner into the port.

-

Turn on the Ignition: Turn the ignition key to the “on” position without starting the engine.

-

Power on the Scanner: The scanner should power on automatically. If not, check the power button.

-

Read Trouble Codes: Follow the scanner’s instructions to read diagnostic trouble codes (DTCs).

-

Interpret the Codes: Use the scanner’s manual or an online database to interpret the meaning of the DTCs.

-

Clear Codes (Optional): If you’ve addressed the underlying issue, you can use the scanner to clear the codes.

-

Test Drive: After clearing the codes, take the vehicle for a test drive to see if the problem returns.

13. Understanding Diagnostic Trouble Codes (DTCs)

Diagnostic Trouble Codes (DTCs) are codes stored by the vehicle’s computer to indicate a problem with a specific system or component. OBD2 systems use standardized DTCs, making it easier to diagnose issues across different makes and models.

13.1 Types of DTCs

DTCs are typically five-character codes consisting of a letter followed by four numbers. The letter indicates the system or area where the fault occurred:

- P: Powertrain (engine, transmission, fuel system)

- B: Body (airbags, power windows, door locks)

- C: Chassis (ABS, suspension, steering)

- U: Network (communication between control modules)

The numbers provide more specific information about the fault. For example, P0300 indicates a random misfire, while P0171 indicates a lean fuel condition.

13.2 Interpreting DTCs

To interpret a DTC, you can use the scanner’s manual, an online database, or a repair manual. These resources provide detailed information about the code, including the potential causes, symptoms, and troubleshooting steps.

13.3 Common DTCs and Their Meanings

| DTC | Description | Possible Causes |

|---|---|---|

| P0300 | Random Misfire | Faulty spark plugs, ignition coils, fuel injectors, vacuum leaks |

| P0171 | System Too Lean (Bank 1) | Vacuum leaks, faulty oxygen sensor, low fuel pressure |

| P0420 | Catalyst System Efficiency Below Threshold | Faulty catalytic converter, oxygen sensors, exhaust leaks |

| P0101 | Mass Air Flow (MAF) Sensor Circuit Range/Performance | Dirty or faulty MAF sensor, vacuum leaks, intake restrictions |

| P0304 | Cylinder 4 Misfire Detected | Faulty spark plug, ignition coil, fuel injector, low compression in cylinder 4 |

13.4 Clearing DTCs

Once you’ve addressed the underlying issue, you can use an OBD2 scanner to clear the DTCs. However, it’s important to note that clearing the codes will not fix the problem. If the underlying issue persists, the codes will likely return.

14. Advanced OBD2 Features

In addition to reading and clearing DTCs, OBD2 systems offer several advanced features that can aid in diagnostics and troubleshooting:

14.1 Real-Time Data Streaming

OBD2 systems can stream real-time data from various sensors and control modules. This allows you to monitor the performance of the engine, transmission, and other systems while the vehicle is running.

14.2 Freeze Frame Data

When a DTC is set, the OBD2 system stores a “freeze frame” of data, which is a snapshot of the sensor readings and operating conditions at the moment the fault occurred. This information can be helpful in diagnosing intermittent issues.

14.3 Oxygen Sensor Testing

OBD2 systems can perform tests on the oxygen sensors to ensure they are functioning correctly. These tests can help identify faulty or degraded oxygen sensors that may be causing emissions problems or performance issues.

14.4 Evaporative Emission Control (EVAP) System Testing

OBD2 systems can perform tests on the EVAP system to check for leaks or malfunctions. These tests can help identify issues that may be causing fuel vapor leaks and emissions problems.

14.5 Mode 6 Data

Mode 6 data provides access to detailed test results from various on-board diagnostic monitors. This information can be helpful in diagnosing complex or intermittent issues that may not trigger a DTC.

15. Choosing the Right OBD2 Scanner

With a wide variety of OBD2 scanners available on the market, choosing the right one can be a daunting task. Here are some factors to consider:

15.1 Features

Consider the features you need. Basic scanners can read and clear DTCs, while more advanced scanners offer real-time data streaming, freeze frame data, oxygen sensor testing, and other advanced features.

15.2 Compatibility

Ensure the scanner is compatible with your vehicle’s make, model, and year. Some scanners are designed to work with specific brands or types of vehicles.

15.3 Ease of Use

Choose a scanner that is easy to use and understand. Look for features like a clear display, intuitive menus, and helpful documentation.

15.4 Price

OBD2 scanners range in price from inexpensive handheld devices to professional-grade tools. Consider your budget and the features you need when making your decision.

15.5 Brand Reputation

Choose a scanner from a reputable brand with a track record of quality and reliability.

15.6 Recommendations for OBD2 Scanners

| Scanner Name | Features | Price |

|---|---|---|

| Autel MaxiCOM MK808 | Reads and clears DTCs, real-time data streaming, freeze frame data, bi-directional control | $500 |

| Launch X431 V+ | Reads and clears DTCs, real-time data streaming, freeze frame data, bi-directional control, ECU coding | $1,000 |

| BlueDriver Bluetooth Professional OBDII Scan Tool | Reads and clears DTCs, real-time data streaming, freeze frame data, repair reports | $120 |

| Innova CarScan Pro 5610 | Reads and clears DTCs, real-time data streaming, freeze frame data, ABS/SRS diagnostics | $200 |

| FOXWELL NT301 OBD2 Scanner | Reads and clears DTCs, I/M readiness, O2 sensor test, EVAP system test | $70 |

16. Future Trends in OBD Technology

OBD technology is constantly evolving to meet the demands of modern vehicles. Here are some future trends to watch for:

16.1 Wireless OBD Adapters

Wireless OBD adapters that connect to smartphones and tablets via Bluetooth or Wi-Fi are becoming increasingly popular. These adapters allow you to use your mobile device as a scan tool and access a wide range of diagnostic information.

16.2 Cloud-Based Diagnostics

Cloud-based diagnostic platforms are emerging that offer advanced features like remote diagnostics, predictive maintenance, and data analytics. These platforms can help mechanics and vehicle owners identify and address issues before they lead to major problems.

16.3 Integration with Autonomous Driving Systems

As autonomous driving technology becomes more prevalent, OBD systems will need to integrate with these systems to monitor their performance and ensure their safety.

16.4 Enhanced Cybersecurity

With the increasing connectivity of modern vehicles, cybersecurity is becoming a major concern. Future OBD systems will need to incorporate enhanced security measures to protect against hacking and unauthorized access.

17. Summary: Is Adding an OBD2 Port to an OBD1 Car Worth It?

While it’s technically possible to add an OBD2 port to an OBD1 car, it’s a complex and costly undertaking that is not recommended for most vehicle owners. The potential benefits of improved diagnostics and emissions monitoring are often outweighed by the challenges, risks, and expenses involved.

Before committing to an OBD2 conversion, consider the following:

- Thoroughly research the compatibility of OBD2 systems with your specific vehicle.

- Assess the cost of parts, labor, and programming.

- Evaluate the potential risks and challenges.

- Consider alternative solutions like high-quality OBD1 scan tools or professional diagnostic services.

At OBD2-SCANNER.EDU.VN, we’re here to help you navigate the complexities of OBD systems and make informed decisions about your vehicle’s diagnostics. Contact us today for expert advice and assistance. Our address is 123 Main Street, Los Angeles, CA 90001, United States. Contact us via Whatsapp: +1 (641) 206-8880. Visit our website: OBD2-SCANNER.EDU.VN

18. Frequently Asked Questions (FAQ)

18.1 What is an OBD2 scanner?

An OBD2 scanner is a tool used to diagnose problems in vehicles manufactured after 1996. It reads diagnostic trouble codes (DTCs) from the vehicle’s computer, providing insights into potential issues.

18.2 How do I read OBD2 codes?

To read OBD2 codes, plug the scanner into the OBD2 port, turn on the ignition, and follow the scanner’s instructions to retrieve the DTCs.

18.3 Can I use an OBD2 scanner on an OBD1 car?

No, OBD2 scanners are not compatible with OBD1 cars due to differences in connectors, protocols, and data parameters.

18.4 What are common OBD2 error codes?

Common OBD2 error codes include P0300 (Random Misfire), P0171 (System Too Lean), and P0420 (Catalyst System Efficiency Below Threshold).

18.5 How do I fix an OBD2 error code?

To fix an OBD2 error code, diagnose the underlying issue using the DTC information and perform the necessary repairs.

18.6 Are all OBD2 scanners the same?

No, OBD2 scanners vary in features, compatibility, ease of use, and price.

18.7 What is the difference between OBD1 and OBD2?

OBD1 is manufacturer-specific and has limited data, while OBD2 is standardized and offers comprehensive diagnostic data.

18.8 How much does an OBD2 scanner cost?

OBD2 scanners range in price from $20 to $1,000, depending on the features and brand.

18.9 Where is the OBD2 port located?

The OBD2 port is typically located under the dashboard on the driver’s side.

18.10 Can I clear OBD2 codes myself?

Yes, you can clear OBD2 codes yourself using an OBD2 scanner. However, it’s important to address the underlying issue first.

Do you have an OBD1 car and need expert advice? Contact us at OBD2-SCANNER.EDU.VN for all your diagnostic needs! Our experts can guide you through the best options for your vehicle. Reach out via Whatsapp: +1 (641) 206-8880 or visit our location at 123 Main Street, Los Angeles, CA 90001, United States.