The Obd2 Bus is your car’s built-in self-diagnostic system that provides access to diagnostic trouble codes (DTCs) and real-time data. This standardized protocol allows technicians and enthusiasts to diagnose and troubleshoot automotive issues efficiently. OBD2-SCANNER.EDU.VN offers comprehensive guides and services to help you understand and utilize the OBD2 bus effectively. Dive in to learn about vehicle diagnostics, scan tool functionality, and the OBD2 communication protocol.

Contents

- 1. Understanding the Basics of the OBD2 Bus

- 1.1 What is the primary function of the OBD2 bus?

- 1.2 Where is the OBD2 port located in my vehicle?

- 1.3 What types of data can I access through the OBD2 bus?

- 2. Key Components of the OBD2 System

- 2.1 What is the role of the OBD2 connector?

- 2.2 How does an OBD2 scanner work?

- 2.3 What is the function of the Engine Control Unit (ECU) in the OBD2 system?

- 3. Decoding OBD2 Protocols and Standards

- 3.1 What is the CAN bus protocol and its role in OBD2?

- 3.2 How do ISO standards relate to OBD2 compliance?

- 3.3 What are SAE standards and their significance in OBD2?

- 4. Common OBD2 Diagnostic Trouble Codes (DTCs)

- 4.1 How do I interpret an OBD2 DTC?

- 4.2 What are the typical causes of a P0300 code?

- 4.3 What steps should I take after reading a P0171 code?

- 5. Utilizing OBD2 Scanners for Vehicle Diagnostics

- 5.1 How do I choose the right OBD2 scanner for my needs?

- 5.2 What are the essential features of a good OBD2 scanner?

- 5.3 Can I use an OBD2 scanner to improve my vehicle’s performance?

- 6. Advanced OBD2 Diagnostics and Troubleshooting

- 6.1 What is bidirectional control and how can it help with diagnostics?

- 6.2 How can freeze frame data assist in diagnosing intermittent issues?

- 6.3 What is the role of component testing in advanced OBD2 diagnostics?

- 7. OBD2 Data Logging and Performance Monitoring

- 7.1 What tools are needed for OBD2 data logging?

- 7.2 How do I interpret OBD2 data logs?

- 7.3 Can OBD2 data logging help improve fuel efficiency?

- 8. Understanding the OBD2 Bus in Electric Vehicles (EVs)

- 8.1 What types of data can be accessed from an EV through the OBD2 bus?

- 8.2 Are there differences in OBD2 functionality between EVs and gasoline vehicles?

- 8.3 What are the limitations of using OBD2 scanners with EVs?

- 9. The Future of OBD and Automotive Diagnostics

- 9.1 How will enhanced connectivity impact OBD diagnostics?

- 9.2 What is predictive maintenance and its role in future vehicle care?

- 9.3 How will remote diagnostics transform the automotive repair industry?

- 10. OBD2 Bus and Vehicle Security

- 10.1 What are the potential security risks associated with the OBD2 bus?

- 10.2 How can I protect my vehicle from OBD2-related security threats?

- 10.3 What security measures are being implemented by manufacturers to safeguard the OBD2 bus?

- FAQ Section

- What does OBD2 stand for?

- Is OBD2 compatible with all vehicles?

- Can I use any OBD2 scanner with my vehicle?

- How often should I scan my vehicle with an OBD2 scanner?

- Are there any risks associated with using an OBD2 scanner?

- Can I clear diagnostic trouble codes (DTCs) with an OBD2 scanner?

- Will clearing DTCs affect my vehicle’s performance?

- How can I stay updated on the latest OBD2 technologies and standards?

- Where can I find reliable information on OBD2 codes and diagnostics?

- What is the best way to learn advanced OBD2 diagnostics?

1. Understanding the Basics of the OBD2 Bus

Do you know what the OBD2 bus is and why it’s essential for modern vehicles?

The OBD2 bus, or On-Board Diagnostics II bus, is a standardized system in vehicles that provides access to a wealth of diagnostic information, and it’s crucial for monitoring and maintaining modern vehicles. According to the EPA, OBD2 was mandated in the United States for all cars manufactured after 1996 to monitor emissions-related components. This technology allows technicians and vehicle owners to quickly identify issues, monitor performance, and ensure their vehicles are running efficiently. It offers a window into the complex systems of your car, making diagnostics and repairs more straightforward than ever before.

1.1 What is the primary function of the OBD2 bus?

The primary function of the OBD2 bus is to monitor vehicle systems and provide diagnostic information, and it serves as a critical tool for both vehicle owners and technicians. The OBD2 system monitors various components, including the engine, transmission, and emissions control systems, ensuring they operate within specified parameters, as stated by the SAE. When a problem is detected, the OBD2 system stores a diagnostic trouble code (DTC), which can be accessed using an OBD2 scanner. This enables quick and accurate identification of issues, reducing diagnostic time and improving repair efficiency.

1.2 Where is the OBD2 port located in my vehicle?

The OBD2 port is typically located under the dashboard on the driver’s side, and this standardized location ensures easy access for diagnostic purposes. While the exact placement can vary slightly depending on the vehicle’s make and model, it is generally within easy reach. Websites like RepairPal provide detailed information on locating the OBD2 port in various vehicles, complete with images and diagrams. This accessibility is a key feature of the OBD2 system, allowing for quick connection of diagnostic tools.

1.3 What types of data can I access through the OBD2 bus?

Through the OBD2 bus, you can access a wide array of real-time data and diagnostic trouble codes (DTCs), which provide insights into your vehicle’s performance and issues. According to the NHTSA, the OBD2 system can provide data on parameters such as engine RPM, vehicle speed, oxygen sensor readings, and coolant temperature. Diagnostic Trouble Codes (DTCs) are standardized codes that pinpoint specific problems within the vehicle’s systems. This wealth of data enables technicians and vehicle owners to diagnose problems accurately, monitor performance, and ensure the vehicle operates efficiently.

2. Key Components of the OBD2 System

What are the essential components that make up the OBD2 system and how do they interact?

The essential components of the OBD2 system include the OBD2 connector, the diagnostic tool (scanner), and the vehicle’s computer (ECU), all of which work together to provide diagnostic information. The OBD2 connector is a standardized port in the vehicle that allows access to the vehicle’s computer. The diagnostic tool, or scanner, plugs into this port and communicates with the ECU to retrieve data and trouble codes. The ECU, or Engine Control Unit, is the vehicle’s main computer that monitors and controls various systems. Understanding these components and their interactions is crucial for effective vehicle diagnostics.

2.1 What is the role of the OBD2 connector?

The OBD2 connector serves as the physical interface for accessing the vehicle’s diagnostic data, and it’s a crucial link for any diagnostic process. This 16-pin connector is standardized across all OBD2-compliant vehicles, ensuring that any OBD2 scanner can be plugged in. As outlined in the SAE J1962 standard, the OBD2 connector provides access to the vehicle’s computer, allowing technicians to read diagnostic trouble codes (DTCs) and monitor real-time data. The OBD2 connector simplifies the diagnostic process, making it easier and more efficient to identify and resolve vehicle issues.

2.2 How does an OBD2 scanner work?

An OBD2 scanner works by connecting to the vehicle’s OBD2 port and communicating with the ECU to retrieve diagnostic information, and it’s an invaluable tool for diagnosing and resolving vehicle issues. According to Bosch, a leading manufacturer of automotive diagnostic equipment, the scanner sends requests to the ECU, which responds with data such as diagnostic trouble codes (DTCs), real-time sensor readings, and other vehicle parameters. The scanner interprets this data and presents it in a user-friendly format, allowing technicians to quickly identify and address problems.

2.3 What is the function of the Engine Control Unit (ECU) in the OBD2 system?

The Engine Control Unit (ECU) serves as the central computer in the OBD2 system, monitoring and controlling various vehicle functions, and it’s essential for maintaining optimal performance and identifying issues. The ECU collects data from numerous sensors throughout the vehicle, including those monitoring engine performance, emissions, and safety systems. As noted by the EPA, when the ECU detects a problem, it stores a diagnostic trouble code (DTC) in its memory. This code can then be accessed by an OBD2 scanner, enabling technicians to diagnose and repair the issue effectively.

3. Decoding OBD2 Protocols and Standards

Can you explain the various OBD2 protocols and standards and how they ensure compatibility?

The various OBD2 protocols and standards, including CAN, ISO, and SAE standards, ensure compatibility across different vehicle makes and models, and they are critical for standardized vehicle diagnostics. The CAN (Controller Area Network) protocol is the most common, used for communication between the ECU and other vehicle components. ISO (International Organization for Standardization) standards, such as ISO 15765, define the communication protocols for OBD2 systems. SAE (Society of Automotive Engineers) standards, like SAE J1979, specify the diagnostic test modes and parameters. These protocols and standards ensure that OBD2 scanners can effectively communicate with and retrieve data from any compliant vehicle.

3.1 What is the CAN bus protocol and its role in OBD2?

The CAN bus protocol is the primary communication standard used in OBD2 systems, and it plays a critical role in facilitating data exchange between the vehicle’s components and diagnostic tools. As defined in ISO 15765-4, CAN bus allows different electronic control units (ECUs) within the vehicle to communicate with each other without a host computer. In the context of OBD2, the CAN bus enables the diagnostic tool to request and receive data from the ECU, including diagnostic trouble codes (DTCs) and real-time sensor readings. This efficient and reliable communication is essential for accurate vehicle diagnostics.

3.2 How do ISO standards relate to OBD2 compliance?

ISO standards, such as ISO 15031 and ISO 15765, provide the framework for OBD2 compliance, and they ensure that diagnostic systems adhere to international quality and performance benchmarks. ISO 15031 specifies the communication between the vehicle and the diagnostic tool, including the format of diagnostic trouble codes (DTCs) and the diagnostic test modes. ISO 15765 defines the CAN bus protocol used for OBD2 communication. Adhering to these ISO standards ensures that OBD2 systems are consistent, reliable, and compatible across different vehicle makes and models, facilitating effective diagnostics and repairs.

3.3 What are SAE standards and their significance in OBD2?

SAE standards, particularly SAE J1979, define the diagnostic test modes and parameters used in OBD2 systems, and they are crucial for standardizing diagnostic processes across the automotive industry. SAE J1979 specifies the standardized set of diagnostic services that all OBD2-compliant vehicles must support, including reading diagnostic trouble codes (DTCs), accessing real-time data, and clearing codes. These standards ensure that technicians can use the same diagnostic procedures for any OBD2-compliant vehicle, regardless of its make or model.

4. Common OBD2 Diagnostic Trouble Codes (DTCs)

What are some common OBD2 Diagnostic Trouble Codes (DTCs) and what do they indicate about your vehicle’s health?

Common OBD2 Diagnostic Trouble Codes (DTCs) include P0300 (Random/Multiple Cylinder Misfire), P0171 (System Too Lean, Bank 1), and P0420 (Catalyst System Efficiency Below Threshold, Bank 1), all of which provide key insights into potential issues. P0300 indicates that the engine is experiencing misfires in one or more cylinders, which can be caused by faulty spark plugs, ignition coils, or fuel injectors. P0171 suggests that the engine is running lean, meaning there is too much air and not enough fuel, potentially due to a vacuum leak or a faulty oxygen sensor. P0420 indicates that the catalytic converter is not functioning efficiently, which could lead to increased emissions. Understanding these common DTCs helps vehicle owners and technicians quickly identify and address potential problems.

4.1 How do I interpret an OBD2 DTC?

To interpret an OBD2 DTC, you need to understand the code’s structure and consult a reliable DTC lookup resource, which will help you accurately diagnose and address vehicle issues. OBD2 DTCs consist of five characters: a letter indicating the system (P for powertrain, B for body, C for chassis, U for network), followed by four numbers. The first number indicates whether the code is generic (0) or manufacturer-specific (1). The remaining three numbers specify the exact fault. Websites like OBD-Codes provide detailed explanations of DTCs, including possible causes and recommended solutions.

4.2 What are the typical causes of a P0300 code?

Typical causes of a P0300 code (Random/Multiple Cylinder Misfire) include faulty spark plugs, ignition coils, fuel injectors, vacuum leaks, or issues with the engine’s compression, all of which can disrupt the combustion process. Spark plugs that are worn, fouled, or improperly gapped can cause misfires. Ignition coils that are failing or damaged may not provide sufficient spark to ignite the fuel-air mixture. Fuel injectors that are clogged or malfunctioning can disrupt the proper fuel delivery. Vacuum leaks can alter the air-fuel mixture, leading to misfires. Addressing these potential causes can help resolve the P0300 code and restore proper engine performance.

4.3 What steps should I take after reading a P0171 code?

After reading a P0171 code (System Too Lean, Bank 1), you should inspect for vacuum leaks, check the mass airflow sensor (MAF), examine the oxygen sensor, and assess the fuel pressure, all of which can help identify the cause of the lean condition. Vacuum leaks can allow unmetered air into the engine, causing a lean mixture. A malfunctioning MAF sensor can provide incorrect data to the ECU, leading to improper fuel delivery. A faulty oxygen sensor can provide inaccurate feedback, causing the ECU to misadjust the air-fuel mixture. Low fuel pressure can result in insufficient fuel delivery to the engine.

5. Utilizing OBD2 Scanners for Vehicle Diagnostics

How can I effectively use OBD2 scanners for vehicle diagnostics and what features should I look for in a scanner?

To effectively use OBD2 scanners for vehicle diagnostics, familiarize yourself with the scanner’s features, connect it properly to the OBD2 port, read and interpret the diagnostic trouble codes (DTCs), and use real-time data to diagnose issues accurately. When selecting a scanner, look for features such as DTC lookup, real-time data streaming, graphing capabilities, and bidirectional control. These features will help you accurately diagnose vehicle issues and monitor performance. Websites like Amazon offer a wide range of OBD2 scanners with detailed product descriptions and customer reviews to help you make an informed choice.

5.1 How do I choose the right OBD2 scanner for my needs?

To choose the right OBD2 scanner for your needs, consider factors such as the scanner’s features, compatibility, ease of use, and price, which will help you find a tool that meets your specific diagnostic requirements. Determine whether you need basic code reading capabilities or more advanced features like real-time data streaming, graphing, and bidirectional control. Check that the scanner is compatible with your vehicle’s make and model. Opt for a scanner with an intuitive interface and clear instructions. Research different brands and models to find a scanner that fits your budget and offers the best value. Reputable brands like Autel and BlueDriver are known for their quality and reliability.

5.2 What are the essential features of a good OBD2 scanner?

Essential features of a good OBD2 scanner include DTC lookup, real-time data streaming, graphing capabilities, bidirectional control, and compatibility with multiple vehicle makes and models, all of which enhance diagnostic accuracy and efficiency. DTC lookup allows you to quickly identify the meaning and potential causes of diagnostic trouble codes. Real-time data streaming provides live sensor readings, enabling you to monitor vehicle performance in real-time. Graphing capabilities allow you to visualize data trends, making it easier to identify intermittent issues. Bidirectional control enables you to send commands to the vehicle’s components, allowing you to test their functionality.

5.3 Can I use an OBD2 scanner to improve my vehicle’s performance?

Yes, you can use an OBD2 scanner to improve your vehicle’s performance by monitoring real-time data, diagnosing issues affecting performance, and ensuring all systems are functioning optimally, which contributes to better efficiency and reliability. By monitoring parameters such as engine RPM, fuel trim, and oxygen sensor readings, you can identify potential problems that may be affecting your vehicle’s performance. Addressing these issues can help improve fuel efficiency, increase horsepower, and ensure smoother operation.

6. Advanced OBD2 Diagnostics and Troubleshooting

What advanced OBD2 diagnostics and troubleshooting techniques can I use for more complex vehicle issues?

Advanced OBD2 diagnostics and troubleshooting involve using bidirectional control, performing component testing, and analyzing freeze frame data, all of which provide deeper insights into complex vehicle issues. Bidirectional control allows you to send commands to the vehicle’s components, enabling you to test their functionality. Component testing involves using the OBD2 scanner to activate and monitor specific components, such as fuel injectors or ignition coils. Freeze frame data captures the vehicle’s operating conditions at the time a diagnostic trouble code (DTC) was set, providing valuable clues for troubleshooting. These advanced techniques require a more sophisticated OBD2 scanner and a deeper understanding of vehicle systems.

6.1 What is bidirectional control and how can it help with diagnostics?

Bidirectional control is an advanced feature in OBD2 scanners that allows technicians to send commands to the vehicle’s components, and it’s invaluable for testing and diagnosing complex issues. With bidirectional control, you can activate components such as fuel injectors, ignition coils, and cooling fans to verify their functionality. For example, you can use bidirectional control to turn on a fuel injector and check if it is spraying fuel properly. This feature helps isolate problems more quickly and accurately, reducing diagnostic time and improving repair efficiency.

6.2 How can freeze frame data assist in diagnosing intermittent issues?

Freeze frame data captures the vehicle’s operating conditions at the moment a diagnostic trouble code (DTC) is set, and it’s extremely valuable for diagnosing intermittent issues that are difficult to replicate. This data includes parameters such as engine RPM, vehicle speed, coolant temperature, and fuel trim values. By analyzing the freeze frame data, you can gain insights into what was happening when the problem occurred, helping you identify the root cause. For example, if a misfire code is set at high RPM, the freeze frame data can help you determine if the issue is related to fuel delivery or ignition.

6.3 What is the role of component testing in advanced OBD2 diagnostics?

Component testing involves using an OBD2 scanner to activate and monitor specific vehicle components, and it plays a crucial role in advanced diagnostics by verifying the functionality of individual parts. This process allows technicians to assess whether components such as fuel injectors, ignition coils, and sensors are operating within their specified parameters. By activating and monitoring these components, technicians can identify whether they are functioning correctly or if they are contributing to the vehicle’s issues. Component testing helps narrow down the source of the problem, leading to more accurate and efficient repairs.

7. OBD2 Data Logging and Performance Monitoring

How can I use OBD2 data logging and performance monitoring to track my vehicle’s health and optimize its performance?

OBD2 data logging and performance monitoring involve recording real-time data, analyzing trends, and identifying areas for improvement, all of which help you track your vehicle’s health and optimize its performance. By recording parameters such as engine RPM, vehicle speed, and fuel consumption over time, you can create a detailed log of your vehicle’s performance. Analyzing this data can help you identify issues such as decreased fuel efficiency, engine misfires, or abnormal sensor readings. With this information, you can take steps to address these issues and optimize your vehicle’s performance.

7.1 What tools are needed for OBD2 data logging?

Tools needed for OBD2 data logging include an OBD2 scanner with data logging capabilities, a laptop or mobile device, and data analysis software, all of which are necessary for collecting and interpreting vehicle performance data. The OBD2 scanner connects to your vehicle’s OBD2 port and records real-time data. A laptop or mobile device is used to store and transfer the logged data. Data analysis software helps you visualize and interpret the data, allowing you to identify trends and potential issues. Popular options include ScanXL and Torque Pro.

7.2 How do I interpret OBD2 data logs?

To interpret OBD2 data logs, analyze trends in parameters such as engine RPM, vehicle speed, fuel consumption, and sensor readings, all of which provide insights into your vehicle’s performance and potential issues. Look for abnormalities such as sudden drops in performance, unusual sensor readings, or inconsistent fuel consumption. Compare the data to baseline values to identify deviations. Use data analysis software to visualize the data and make it easier to identify trends. Understanding these trends can help you diagnose problems and optimize your vehicle’s performance.

7.3 Can OBD2 data logging help improve fuel efficiency?

Yes, OBD2 data logging can help improve fuel efficiency by monitoring parameters such as fuel consumption, engine load, and air-fuel ratio, all of which provide insights into how efficiently your vehicle is running. By tracking these parameters over time, you can identify driving habits or mechanical issues that are affecting fuel efficiency. For example, you may find that excessive idling or aggressive acceleration is contributing to poor fuel economy. Addressing these issues can help you improve fuel efficiency and save money on gas.

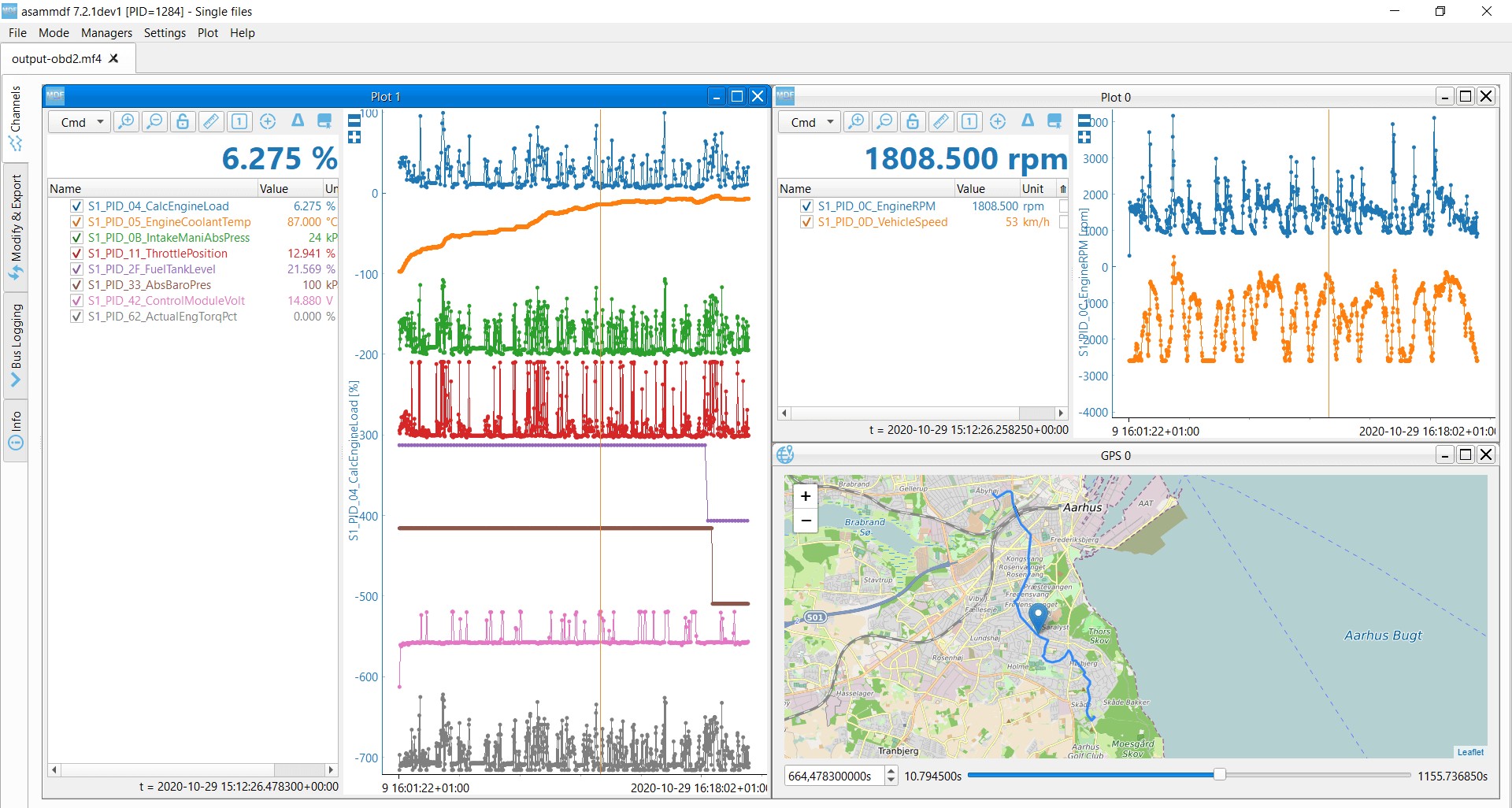

OBD2 data decoded visual plot asammdf CAN bus DBC file

OBD2 data decoded visual plot asammdf CAN bus DBC file

8. Understanding the OBD2 Bus in Electric Vehicles (EVs)

How does the OBD2 bus function in Electric Vehicles (EVs) and what unique data can be accessed?

In Electric Vehicles (EVs), the OBD2 bus provides access to data related to the battery, motor, and charging system, but its functionality is often limited compared to traditional vehicles. While EVs still use the OBD2 port for diagnostics, the data available is often different, focusing on EV-specific parameters such as battery voltage, state of charge, and motor temperature. The EPA notes that EVs are not required to support all the standard OBD2 functions related to emissions, as they do not have an internal combustion engine. Understanding these differences is crucial for effectively diagnosing and maintaining EVs.

8.1 What types of data can be accessed from an EV through the OBD2 bus?

Through the OBD2 bus in an EV, you can access data such as battery voltage, state of charge (SOC), motor temperature, and charging system status, all of which are crucial for monitoring the health and performance of the EV. Battery voltage indicates the overall health of the battery pack. The SOC provides information on the current charge level of the battery. Motor temperature helps ensure the motor is operating within safe limits. Charging system status provides data on the charging process, including voltage and current. These parameters help EV owners and technicians monitor the EV’s vital systems.

8.2 Are there differences in OBD2 functionality between EVs and gasoline vehicles?

Yes, there are differences in OBD2 functionality between EVs and gasoline vehicles, with EVs focusing on battery and motor data rather than emissions-related parameters. EVs do not have an internal combustion engine, so they do not require the same emissions monitoring as gasoline vehicles. As a result, EV OBD2 systems focus on data related to the battery, motor, and charging system. While some standard OBD2 codes may still apply, many EV-specific codes are used to diagnose and troubleshoot issues unique to electric vehicles.

8.3 What are the limitations of using OBD2 scanners with EVs?

Limitations of using OBD2 scanners with EVs include limited access to proprietary data, variations in data availability between manufacturers, and the need for EV-specific diagnostic tools, all of which can complicate the diagnostic process. Many EV manufacturers use proprietary diagnostic protocols that are not accessible through standard OBD2 scanners. The data available through the OBD2 port can vary significantly between different EV makes and models. Some EV-specific diagnostic tools are required to access and interpret the full range of data available from the vehicle’s systems.

9. The Future of OBD and Automotive Diagnostics

What does the future hold for OBD and automotive diagnostics, and how will technology advancements shape this field?

The future of OBD and automotive diagnostics includes enhanced connectivity, predictive maintenance, and remote diagnostics, all of which will be driven by technological advancements. Enhanced connectivity will allow vehicles to communicate with diagnostic tools and service providers in real-time. Predictive maintenance will use data analytics to identify potential issues before they lead to breakdowns. Remote diagnostics will enable technicians to diagnose and repair vehicles from a distance. These advancements will make vehicle maintenance more efficient, convenient, and cost-effective.

9.1 How will enhanced connectivity impact OBD diagnostics?

Enhanced connectivity will revolutionize OBD diagnostics by enabling real-time data streaming, remote diagnostics, and over-the-air updates, all of which will enhance the efficiency and effectiveness of vehicle maintenance. Real-time data streaming will allow technicians to monitor vehicle performance remotely. Remote diagnostics will enable technicians to diagnose and repair vehicles from a distance. Over-the-air updates will allow manufacturers to update vehicle software and diagnostic tools remotely. These advancements will make vehicle maintenance more convenient and cost-effective.

9.2 What is predictive maintenance and its role in future vehicle care?

Predictive maintenance involves using data analytics to identify potential vehicle issues before they lead to breakdowns, and it promises to revolutionize vehicle care by improving reliability and reducing downtime. By monitoring parameters such as engine performance, component health, and operating conditions, predictive maintenance systems can detect early signs of wear or malfunction. This allows technicians to address issues proactively, preventing costly repairs and improving vehicle uptime.

9.3 How will remote diagnostics transform the automotive repair industry?

Remote diagnostics will transform the automotive repair industry by enabling technicians to diagnose and repair vehicles from a distance, reducing the need for physical inspections and improving service efficiency. Remote diagnostics can provide real-time data and diagnostic information to technicians, allowing them to identify problems and recommend solutions without the vehicle being physically present. This technology can reduce diagnostic time, improve repair accuracy, and enable service providers to reach customers in remote locations. This transformative approach is set to redefine how automotive repairs are conducted.

10. OBD2 Bus and Vehicle Security

What are the security considerations related to the OBD2 bus and how can I protect my vehicle from potential threats?

Security considerations related to the OBD2 bus include the risk of unauthorized access, data theft, and vehicle hacking, all of which highlight the importance of protecting your vehicle from potential threats. The OBD2 port provides a direct connection to the vehicle’s computer systems, making it a potential entry point for malicious actors. To protect your vehicle, use reputable OBD2 scanners, keep your vehicle’s software updated, and consider using a security device that blocks unauthorized access to the OBD2 port. Staying informed and taking proactive measures can help safeguard your vehicle from security threats.

10.1 What are the potential security risks associated with the OBD2 bus?

Potential security risks associated with the OBD2 bus include unauthorized access to vehicle systems, data theft, and the potential for vehicle hacking, all of which can compromise the security and integrity of your vehicle. Unauthorized access can allow malicious actors to manipulate vehicle functions, such as disabling brakes or controlling the engine. Data theft can expose sensitive information about the vehicle and its owner. Vehicle hacking can allow attackers to take complete control of the vehicle, posing a serious safety risk.

10.2 How can I protect my vehicle from OBD2-related security threats?

To protect your vehicle from OBD2-related security threats, use reputable OBD2 scanners, keep your vehicle’s software updated, and consider using a security device that blocks unauthorized access to the OBD2 port, all of which enhance your vehicle’s security. Reputable OBD2 scanners are less likely to contain malicious software. Keeping your vehicle’s software updated ensures that it has the latest security patches. A security device that blocks unauthorized access to the OBD2 port can prevent hackers from gaining control of your vehicle.

10.3 What security measures are being implemented by manufacturers to safeguard the OBD2 bus?

Manufacturers are implementing security measures such as encryption, authentication protocols, and intrusion detection systems to safeguard the OBD2 bus, all of which aim to protect vehicles from unauthorized access and cyber threats. Encryption helps protect data transmitted over the OBD2 bus. Authentication protocols verify the identity of diagnostic tools and technicians. Intrusion detection systems monitor the OBD2 bus for suspicious activity. These measures help ensure the security and integrity of vehicle systems.

FAQ Section

What does OBD2 stand for?

OBD2 stands for On-Board Diagnostics II, a standardized system used in vehicles to monitor and diagnose various components, including the engine, transmission, and emissions control systems.

Is OBD2 compatible with all vehicles?

OBD2 is generally compatible with most vehicles manufactured after 1996 in the United States, 2001 for gasoline cars in the EU, and 2003 for diesel cars in the EU.

Can I use any OBD2 scanner with my vehicle?

While OBD2 is a standardized system, it is essential to check that the scanner is compatible with your vehicle’s make and model. Some advanced features may not be supported on all vehicles.

How often should I scan my vehicle with an OBD2 scanner?

You should scan your vehicle with an OBD2 scanner whenever the check engine light comes on or if you notice any unusual performance issues. Regular scanning can also help identify potential problems early.

Are there any risks associated with using an OBD2 scanner?

When used correctly, there are minimal risks associated with using an OBD2 scanner. However, it is essential to use a reputable scanner and follow the manufacturer’s instructions to avoid damaging your vehicle’s systems.

Can I clear diagnostic trouble codes (DTCs) with an OBD2 scanner?

Yes, you can clear diagnostic trouble codes (DTCs) with an OBD2 scanner, but it is essential to understand the underlying issue first. Clearing the code without addressing the problem may result in the code reappearing.

Will clearing DTCs affect my vehicle’s performance?

Clearing DTCs will not typically affect your vehicle’s performance, but it will reset the check engine light and any associated performance adaptations. The vehicle may need to relearn certain parameters after the codes are cleared.

How can I stay updated on the latest OBD2 technologies and standards?

To stay updated on the latest OBD2 technologies and standards, follow industry publications, attend automotive conferences, and consult with reputable diagnostic tool manufacturers like OBD2-SCANNER.EDU.VN.

Where can I find reliable information on OBD2 codes and diagnostics?

You can find reliable information on OBD2 codes and diagnostics on websites like OBD-Codes, RepairPal, and through resources provided by reputable diagnostic tool manufacturers like OBD2-SCANNER.EDU.VN.

What is the best way to learn advanced OBD2 diagnostics?

The best way to learn advanced OBD2 diagnostics is through hands-on experience, combined with training courses, industry certifications, and guidance from experienced technicians.

Understanding the OBD2 bus is crucial for maintaining and optimizing your vehicle’s performance. By utilizing the information and services provided by OBD2-SCANNER.EDU.VN, you can effectively diagnose and address automotive issues, ensuring your vehicle runs smoothly and efficiently.

Don’t let vehicle problems slow you down. Contact OBD2-SCANNER.EDU.VN today for expert guidance and top-notch services in OBD2 diagnostics and vehicle repair. Call us at +1 (641) 206-8880 or visit our location at 123 Main Street, Los Angeles, CA 90001, United States. You can also reach us via Whatsapp or explore our website at OBD2-SCANNER.EDU.VN for more information. Let us help you keep your vehicle in peak condition.