The Obd2 Spec serves as your vehicle’s built-in self-diagnostic system, a standardized protocol enabling the extraction of diagnostic trouble codes (DTCs) and real-time data through the OBD2 connector, and at OBD2-SCANNER.EDU.VN, we help you understand and utilize this specification to its full potential. This article explores the OBD2 spec, its history, present applications, and future trends, offering you a comprehensive guide to vehicle diagnostics, and understanding of automotive protocols, emission control systems, and vehicle telematics.

Contents

- 1. Understanding the OBD2 Spec

- 1.1. What Is the Purpose of OBD2?

- 1.2. Key Components of the OBD2 Spec

- 2. A Brief History of the OBD2 Spec

- 2.1. Early Origins

- 2.2. Standardization Efforts

- 2.3. OBD2 Mandates

- 3. Advantages of Using the OBD2 Spec

- 3.1. Improved Diagnostics

- 3.2. Cost Savings

- 3.3. Environmental Benefits

- 3.4. Standardized Data

- 4. OBD2 Connector Details

- 4.1. Location in the Vehicle

- 4.2. Pinout Configuration

- 4.3. Type A vs. Type B

- 5. OBD2 Communication Protocols

- 5.1. CAN Bus

- 5.2. ISO 15765-4 (DoCAN)

- 5.3. Other Protocols

- 6. Diagnostic Trouble Codes (DTCs)

- 6.1. Structure of DTCs

- 6.2. Common DTCs

- 6.3. DTC Lookup Tools

- 7. Parameter IDs (PIDs)

- 7.1. Standardized PIDs

- 7.2. Special PID: 0x00

- 7.3. OBD2 PID Overview Tool

- 8. How to Use an OBD2 Scanner

- 8.1. Connecting the Scanner

- 8.2. Reading DTCs

- 8.3. Interpreting the Data

- 8.4. Clearing Codes

- 9. Common OBD2 Scanner Mistakes to Avoid

- 9.1. Ignoring Freeze Frame Data

- 9.2. Clearing Codes Without Addressing the Issue

- 9.3. Using Incompatible Scanners

- 9.4. Neglecting Regular Updates

- 10. OBD2 Data Logging and Decoding

- 10.1. Using a CAN Bus Data Logger

- 10.2. Configuring PID Requests

- 10.3. DBC Decoding

- 11. The Future of OBD2 and OBD3

- 11.1. Telematics Integration

- 11.2. Alternatives to OBD2

- 11.3. Electric Vehicles and OBD2

- 12. OBD2 and Proprietary CAN Protocols

- 12.1. OEM-Specific Protocols

- 12.2. OBD2 as an Extra Layer

- 12.3. Gateway Blocking

- 13. ISO-TP and Multi-Frame Communication

- 13.1. Segmentation and Reassembly

- 13.2. Single Frame Communication

- 13.3. Multi-Frame Examples

- 14. Practical Applications of OBD2 Data Logging

- 14.1. Fuel Efficiency Optimization

- 14.2. Driver Behavior Monitoring

- 14.3. Predictive Maintenance

- 14.4. Vehicle Tracking and Telematics

- 15. Choosing the Right OBD2 Scanner for Your Needs

- 15.1. Basic Scanners

- 15.2. Advanced Scanners

- 15.3. Professional-Grade Scanners

- 15.4. Compatibility

- 16. Navigating OBD2 Modes and Services

- 16.1. Mode 0x01: Show Current Data

- 16.2. Mode 0x03: Show Stored DTCs

- 16.3. Mode 0x04: Clear DTCs

- 16.4. Other Modes

- 17. Addressing Common OBD2-Related Problems

- 17.1. Scanner Not Connecting

- 17.2. Inaccurate Data

- 17.3. Communication Errors

- 17.4. Unsupported PIDs

- 18. Optimizing Your Car’s Performance with OBD2 Data

- 18.1. Improving Fuel Economy

- 18.2. Enhancing Engine Performance

- 18.3. Reducing Emissions

- 18.4. Extending Vehicle Lifespan

- 19. OBD2 Compliance and Legal Requirements

- 19.1. Emission Standards

- 19.2. Vehicle Inspections

- 19.3. Legal Penalties

- 19.4. Consumer Protection

- 20. Frequently Asked Questions (FAQs) About OBD2 Spec

- 20.1. What is an OBD2 Scanner?

- 20.2. How Do I Know If My Car Is OBD2 Compliant?

- 20.3. Can I Use an OBD2 Scanner on Any Car?

- 20.4. What Do DTCs Mean?

- 20.5. Is It Safe to Clear DTCs Myself?

- 20.6. What Is the Difference Between OBD2 and OBD1?

- 20.7. How Often Should I Use an OBD2 Scanner?

- 20.8. Do Electric Vehicles Use OBD2?

- 20.9. What Are PIDs?

- 20.10. Can OBD2 Data Help Improve Fuel Efficiency?

1. Understanding the OBD2 Spec

What does the OBD2 specification actually entail? The OBD2 (On-Board Diagnostics II) specification is a set of standards and protocols implemented in vehicles to monitor and report on their performance.

It’s your car’s way of communicating potential issues, offering a standardized method for accessing diagnostic information. Imagine the OBD2 spec as a universal translator for your car, allowing mechanics and car owners alike to understand what’s happening under the hood.

1.1. What Is the Purpose of OBD2?

The main purpose is to monitor vehicle emissions and engine performance. The OBD2 spec was initially introduced to ensure vehicles met specific emission standards, it has evolved to offer a wealth of data points beyond emissions, helping to diagnose a wide range of issues. Think of it as a health monitor for your car, constantly checking vital signs and alerting you to potential problems.

1.2. Key Components of the OBD2 Spec

The key components include:

- OBD2 Connector: The physical interface used to access the vehicle’s diagnostic data.

- Diagnostic Trouble Codes (DTCs): Standardized codes used to identify specific issues within the vehicle.

- Parameter IDs (PIDs): Identifiers for specific data parameters that can be requested and read from the vehicle’s computer.

- Communication Protocols: The language used to communicate between the diagnostic tool and the vehicle.

2. A Brief History of the OBD2 Spec

Where did the OBD2 spec originate and how has it evolved over time? The OBD2 spec’s history is rooted in the need for better emission control and diagnostics.

2.1. Early Origins

The story begins in California, where the California Air Resources Board (CARB) mandated OBD systems in new cars from 1991 onward for emission control.

2.2. Standardization Efforts

The Society of Automotive Engineers (SAE) played a crucial role in standardizing DTCs and the OBD connector, resulting in SAE J1962. This standardization was essential for ensuring compatibility across different vehicle manufacturers.

2.3. OBD2 Mandates

The OBD2 spec was gradually rolled out:

- 1996: Mandatory in the USA for cars and light trucks.

- 2001: Required in the EU for gasoline cars.

- 2003: Also required in the EU for diesel cars (EOBD).

- 2005: Required in the US for medium-duty vehicles.

- 2008: US cars must use ISO 15765-4 (CAN) as the OBD2 basis.

- 2010: Finally required in US heavy-duty vehicles.

3. Advantages of Using the OBD2 Spec

Why should car owners and mechanics use the OBD2 spec? The advantages are numerous, offering benefits to both vehicle owners and service professionals.

3.1. Improved Diagnostics

The OBD2 spec allows for more accurate and comprehensive diagnostics, leading to faster and more effective repairs. By providing standardized codes and data parameters, it simplifies the process of identifying and resolving vehicle issues.

3.2. Cost Savings

By enabling early detection of problems, the OBD2 spec can help prevent costly repairs down the line. Regular diagnostic checks can catch minor issues before they escalate into major problems.

3.3. Environmental Benefits

The OBD2 spec helps ensure that vehicles meet emission standards, contributing to a cleaner environment. By monitoring emissions-related components, it helps identify and resolve issues that could lead to increased pollution.

3.4. Standardized Data

The OBD2 spec provides standardized data across different vehicle models and manufacturers, making it easier for mechanics to work on a wide range of vehicles. This standardization reduces the learning curve and simplifies the diagnostic process.

4. OBD2 Connector Details

What are the specifics of the OBD2 connector? The OBD2 connector, also known as the Data Link Connector (DLC), is a standardized 16-pin interface that provides access to the vehicle’s diagnostic data.

4.1. Location in the Vehicle

The connector is typically located near the steering wheel but may be hidden. Its standardized location ensures easy access for diagnostic tools.

4.2. Pinout Configuration

The OBD2 pinout depends on the communication protocol, but pin 16 always supplies battery power. The most common lower-layer protocol is CAN bus, with pins 6 (CAN-H) and 14 (CAN-L) typically connected.

4.3. Type A vs. Type B

You may encounter both type A and type B OBD2 connectors. Type A is common in cars, while type B is common in medium and heavy-duty vehicles. The two types share similar pinouts but provide different power supply outputs (12V for type A and 24V for type B).

5. OBD2 Communication Protocols

What communication protocols are used in the OBD2 spec? Communication protocols are essential for the diagnostic tool and the vehicle’s computer to communicate effectively.

5.1. CAN Bus

Since 2008, CAN bus has been the mandatory lower-layer protocol for OBD2 in all cars sold in the US, as per ISO 15765. ISO 15765-4 (Diagnostics over CAN or DoCAN) standardizes the CAN interface for test equipment, focusing on the physical, data link, and network layers.

5.2. ISO 15765-4 (DoCAN)

This standard specifies that the CAN bus bit-rate must be either 250K or 500K, the CAN IDs can be 11-bit or 29-bit, specific CAN IDs are used for OBD requests/responses, the diagnostic CAN frame data length must be 8 bytes, and the OBD2 adapter cable must be max 5 meters.

5.3. Other Protocols

Before CAN bus became the standard, other protocols were used, including ISO 14230-4 (KWP2000), ISO 9141-2, SAE J1850 (VPW), and SAE J1850 (PWM). Knowing these protocols is useful when inspecting older cars (pre-2008).

6. Diagnostic Trouble Codes (DTCs)

What are Diagnostic Trouble Codes (DTCs) and how are they used? DTCs are standardized codes used to identify specific issues within the vehicle.

6.1. Structure of DTCs

The 2-byte DTC value is typically split into two parts, with the first 2 bits defining the category and the remaining 14 bits defining a 4-digit code (displayed in hexadecimal), as per ISO 15031-5/ISO 15031-6.

6.2. Common DTCs

Some common DTCs include P0300 (Random/Multiple Cylinder Misfire Detected), P0171 (System Too Lean, Bank 1), and P0420 (Catalyst System Efficiency Below Threshold, Bank 1). Each code corresponds to a specific issue that needs to be addressed.

6.3. DTC Lookup Tools

Decoded DTC values can be looked up in various OBD2 DTC lookup tools, such as repairpal.com, to understand the specific issue and how to resolve it.

7. Parameter IDs (PIDs)

What are Parameter IDs (PIDs) and how are they used? PIDs are identifiers for specific data parameters that can be requested and read from the vehicle’s computer.

7.1. Standardized PIDs

Each OBD2 mode contains PIDs. As an example, mode 0x01 contains ~200 standardized PIDs with real-time data on e.g. speed, RPM, and fuel level. However, a vehicle does not have to support all OBD2 PIDs in a mode.

7.2. Special PID: 0x00

If an emissions-related ECU supports any OBD2 services, then it must support mode 0x01 PID 0x00. In response to this PID, the vehicle ECU informs whether it supports PIDs 0x01-0x20. This makes PID 0x00 useful as a fundamental ‘OBD2 compatibility test’.

7.3. OBD2 PID Overview Tool

In the appendices of SAE J1979 and ISO 15031-5, you will find scaling info for standard OBD2 PIDs, which allows you to decode the data into physical values. Tools like the OBD2 PID overview tool can help construct OBD2 request frames and dynamically decode the OBD2 responses.

8. How to Use an OBD2 Scanner

How do you use an OBD2 scanner to retrieve diagnostic data? Using an OBD2 scanner is a straightforward process that can provide valuable insights into your vehicle’s health.

8.1. Connecting the Scanner

First, locate the OBD2 connector in your vehicle. It’s typically found under the dashboard, near the steering wheel. Plug the OBD2 scanner into the connector.

8.2. Reading DTCs

Turn on the vehicle’s ignition but don’t start the engine. The scanner should power on and begin communicating with the vehicle’s computer. Use the scanner’s interface to read any stored DTCs.

8.3. Interpreting the Data

Once you have the DTCs, use a lookup tool to understand what each code means. The scanner may also display real-time data parameters such as engine speed, coolant temperature, and oxygen sensor readings.

8.4. Clearing Codes

After addressing the issues indicated by the DTCs, you can use the scanner to clear the codes. Keep in mind that some codes may reappear if the underlying problem is not fully resolved.

9. Common OBD2 Scanner Mistakes to Avoid

What are some common mistakes to avoid when using an OBD2 scanner? Avoiding these mistakes can help ensure accurate diagnostics and prevent potential issues.

9.1. Ignoring Freeze Frame Data

Freeze frame data provides a snapshot of the vehicle’s operating conditions when a DTC was triggered. Ignoring this data can make it harder to diagnose the underlying problem.

9.2. Clearing Codes Without Addressing the Issue

Clearing codes without fixing the problem is a temporary solution that can lead to more severe issues down the road. Always address the root cause of the DTC before clearing the code.

9.3. Using Incompatible Scanners

Using an OBD2 scanner that is not compatible with your vehicle’s make, model, and year can result in inaccurate data or communication errors. Always verify compatibility before using a scanner.

9.4. Neglecting Regular Updates

OBD2 scanners require regular software updates to stay current with new vehicle models and DTCs. Neglecting these updates can result in outdated or inaccurate information.

10. OBD2 Data Logging and Decoding

How can you log and decode OBD2 data for more in-depth analysis? Logging and decoding OBD2 data can provide a more detailed understanding of your vehicle’s performance.

10.1. Using a CAN Bus Data Logger

Tools like the CANedge can be used to log OBD2 data. The CANedge allows you to configure custom CAN frames to be transmitted, making it suitable for OBD2 logging.

10.2. Configuring PID Requests

Configure your transmit list with PIDs of interest. Consider using Physical Addressing request IDs to avoid multiple responses, adding spacing between requests to prevent ECU overload, using triggers to stop transmitting when the vehicle is inactive, and adding filters to only record OBD2 responses.

10.3. DBC Decoding

To analyze/visualize your data, you need to decode the raw OBD2 data into physical values. Use an OBD2 DBC file to DBC decode raw OBD2 data in most CAN bus software tools.

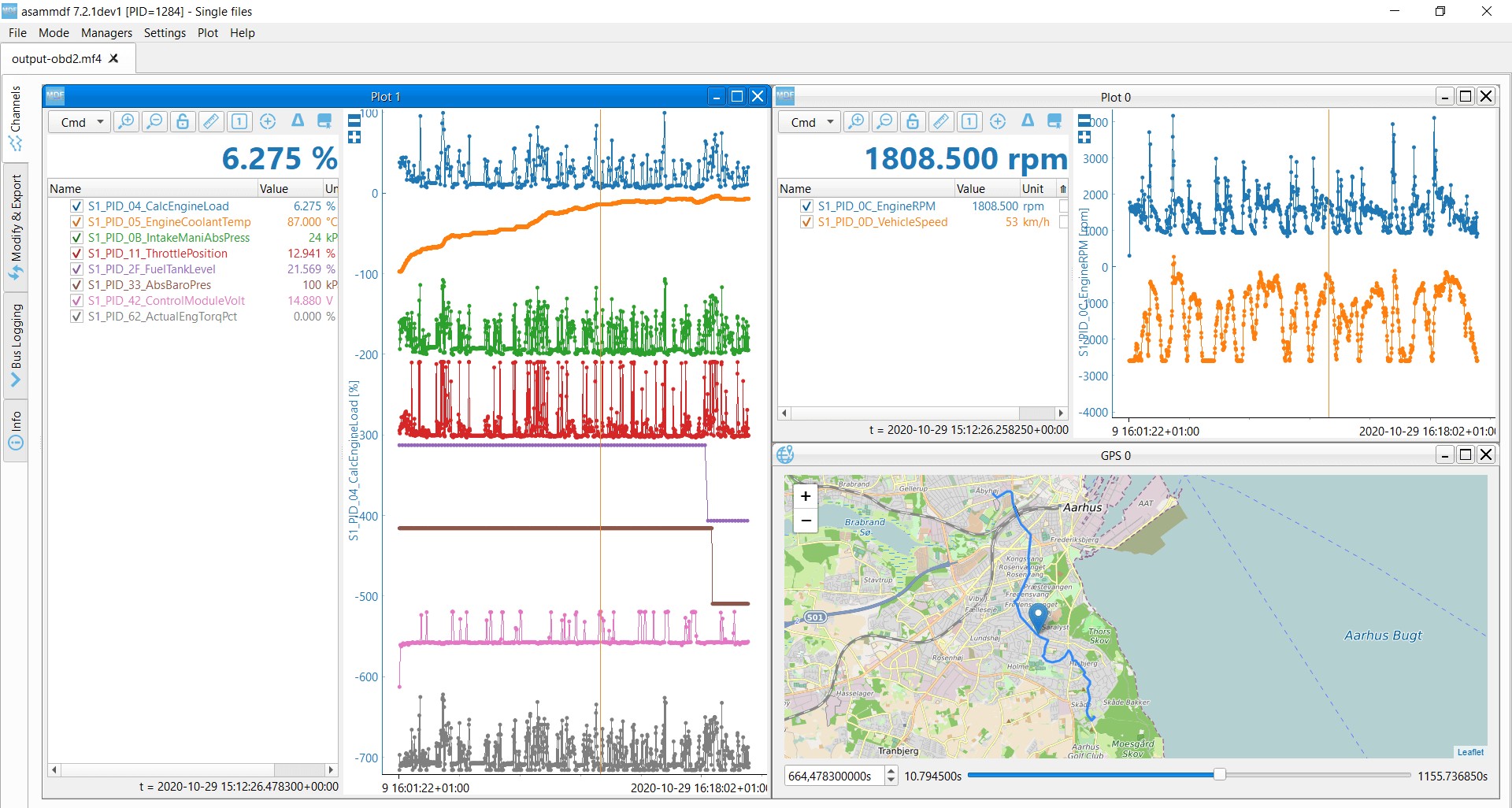

OBD2 data decoded visual plot asammdf CAN bus DBC file

OBD2 data decoded visual plot asammdf CAN bus DBC file

11. The Future of OBD2 and OBD3

What does the future hold for OBD2 and the emergence of OBD3? The future of OBD2 is evolving with advancements in automotive technology and connectivity.

11.1. Telematics Integration

OBD3 aims to add telematics to all cars, using a small radio transponder to send the VIN and DTCs via WiFi to a central server for checks. This saves cost and is convenient but also presents political challenges due to surveillance concerns.

11.2. Alternatives to OBD2

Modern alternatives have been developed, including WWH-OBD (World Wide Harmonized OBD) and OBDonUDS (OBD on UDS). Both seek to streamline and enhance OBD communication by leveraging the UDS protocol as a basis.

11.3. Electric Vehicles and OBD2

Electric vehicles are not required to support OBD2 in any shape or form. Most modern EVs utilize OEM-specific UDS communication. This generally makes it impossible to decode data from these electric vehicles, except for cases where the decoding rules have been reverse-engineered.

12. OBD2 and Proprietary CAN Protocols

What is the difference between OBD2 and proprietary CAN protocols? Understanding the distinction between OBD2 and proprietary CAN protocols is essential for advanced diagnostics.

12.1. OEM-Specific Protocols

Each Original Equipment Manufacturer (OEM) implements their own proprietary CAN protocols for their Electronic Control Units (ECUs) to function. These CAN protocols may be specific to the vehicle brand, model, and year.

12.2. OBD2 as an Extra Layer

OBD2 can be thought of as an “extra” higher-layer protocol in parallel to the OEM-specific protocol. It provides standardized access to certain diagnostic data but does not replace the OEM’s internal communication protocols.

12.3. Gateway Blocking

In many newer cars, a gateway blocks access to the OEM-specific CAN data and only enables OBD2 communication via the OBD2 connector. This is done to protect the vehicle’s internal systems and prevent unauthorized access.

13. ISO-TP and Multi-Frame Communication

How does ISO-TP facilitate multi-frame communication in OBD2? ISO-TP (ISO 15765-2) is a transport protocol used to communicate OBD2 data on the CAN bus. It enables the communication of payloads that exceed 8 bytes, which is necessary when extracting the Vehicle Identification Number (VIN) or Diagnostic Trouble Codes (DTCs).

13.1. Segmentation and Reassembly

ISO 15765-2 enables segmentation, flow control, and reassembly of larger data packets. This ensures that data is transmitted and received correctly, even when it exceeds the size limitations of a single CAN frame.

13.2. Single Frame Communication

Often, however, the OBD2 data will fit in a single CAN frame. In this case, ISO 15765-2 specifies the use of a ‘Single Frame’ (SF), where the 1st data byte (aka PCI field) contains the payload length, leaving 7 bytes for the OBD2-related communication.

13.3. Multi-Frame Examples

Multi-frame OBD2 communication requires flow control frames. Examples of multi-frame communication include extracting the VIN, requesting multiple PIDs in one request, and retrieving Diagnostic Trouble Codes (DTCs).

14. Practical Applications of OBD2 Data Logging

What are some real-world applications of OBD2 data logging? OBD2 data logging can be used in a variety of applications to improve vehicle performance, maintenance, and diagnostics.

14.1. Fuel Efficiency Optimization

By logging data such as fuel consumption, engine speed, and throttle position, you can identify areas where fuel efficiency can be improved. This can lead to cost savings and reduced emissions.

14.2. Driver Behavior Monitoring

OBD2 data can be used to monitor driver behavior, such as speeding, hard braking, and aggressive acceleration. This information can be used to provide feedback to drivers and improve safety.

14.3. Predictive Maintenance

By analyzing OBD2 data over time, you can identify patterns and predict potential maintenance issues before they lead to breakdowns. This allows for proactive maintenance and reduces the risk of unexpected repairs.

14.4. Vehicle Tracking and Telematics

OBD2 data can be integrated with vehicle tracking and telematics systems to provide real-time information about vehicle location, performance, and diagnostics. This is useful for fleet management and vehicle security.

15. Choosing the Right OBD2 Scanner for Your Needs

How do you select the best OBD2 scanner for your specific needs? Selecting the right OBD2 scanner depends on your specific needs and budget.

15.1. Basic Scanners

Basic scanners are inexpensive and easy to use. They typically provide DTCs and basic real-time data.

15.2. Advanced Scanners

Advanced scanners offer more features, such as enhanced diagnostics, bi-directional control, and advanced data logging. These scanners are typically more expensive but provide more comprehensive capabilities.

15.3. Professional-Grade Scanners

Professional-grade scanners are designed for use in repair shops and offer the most advanced features and capabilities. These scanners are typically the most expensive but are essential for professional mechanics.

15.4. Compatibility

Ensure that the scanner is compatible with your vehicle’s make, model, and year. Some scanners are designed to work with specific vehicle types, while others are more universal.

16. Navigating OBD2 Modes and Services

How do you navigate the different OBD2 modes and services? Understanding the different OBD2 modes and services is essential for effective diagnostics.

16.1. Mode 0x01: Show Current Data

Mode 0x01 displays current real-time data, such as engine speed, coolant temperature, and oxygen sensor readings. This mode is useful for monitoring vehicle performance and identifying potential issues.

16.2. Mode 0x03: Show Stored DTCs

Mode 0x03 shows stored Diagnostic Trouble Codes (DTCs). This mode is used to retrieve any stored codes that indicate potential issues with the vehicle.

16.3. Mode 0x04: Clear DTCs

Mode 0x04 clears Diagnostic Trouble Codes (DTCs). This mode is used to clear any stored codes after addressing the underlying issues.

16.4. Other Modes

Other modes include mode 0x02 (Show Freeze Frame Data), mode 0x05 (Show Oxygen Sensor Test Results), mode 0x06 (Show On-Board Monitoring Test Results), mode 0x07 (Show Pending DTCs), mode 0x08 (Control On-Board System), mode 0x09 (Request Vehicle Information), and mode 0x0A (Show Permanent DTCs).

17. Addressing Common OBD2-Related Problems

What are some common problems encountered when using OBD2 and how can they be resolved? Addressing common OBD2-related problems can help ensure accurate diagnostics and prevent frustration.

17.1. Scanner Not Connecting

If the scanner is not connecting to the vehicle, check the OBD2 connector for damage or corrosion. Also, ensure that the scanner is compatible with the vehicle and that the ignition is turned on.

17.2. Inaccurate Data

If the scanner is displaying inaccurate data, check for software updates and verify that the scanner is properly calibrated. Also, ensure that the scanner is compatible with the vehicle and that the data parameters are being interpreted correctly.

17.3. Communication Errors

If the scanner is displaying communication errors, check the CAN bus connections and ensure that the vehicle is not experiencing any electrical issues. Also, try using a different scanner or communication protocol.

17.4. Unsupported PIDs

If the scanner is unable to read certain PIDs, it may be because the vehicle does not support those parameters. Check the vehicle’s documentation to determine which PIDs are supported.

18. Optimizing Your Car’s Performance with OBD2 Data

How can you use OBD2 data to optimize your car’s performance? OBD2 data can be used to optimize various aspects of your car’s performance.

18.1. Improving Fuel Economy

By monitoring fuel consumption, engine speed, and throttle position, you can identify areas where fuel economy can be improved. Adjusting driving habits and performing regular maintenance can help optimize fuel efficiency.

18.2. Enhancing Engine Performance

By monitoring engine parameters such as air-fuel ratio, ignition timing, and boost pressure, you can identify potential issues and optimize engine performance. Tuning the engine and replacing worn components can help enhance performance.

18.3. Reducing Emissions

By monitoring emissions-related components such as oxygen sensors and catalytic converters, you can identify potential issues and reduce emissions. Performing regular maintenance and replacing faulty components can help reduce emissions.

18.4. Extending Vehicle Lifespan

By monitoring various vehicle parameters and performing regular maintenance, you can extend the lifespan of your vehicle. Addressing potential issues early can prevent more severe problems down the road.

19. OBD2 Compliance and Legal Requirements

What are the legal requirements related to OBD2 compliance? OBD2 compliance is essential for ensuring that vehicles meet emission standards and safety regulations.

19.1. Emission Standards

OBD2 compliance is required to meet emission standards set by regulatory agencies such as the Environmental Protection Agency (EPA) in the United States and the European Union.

19.2. Vehicle Inspections

Many states and countries require OBD2 testing as part of their vehicle inspection programs. Vehicles that fail OBD2 testing may not be allowed to operate on public roads.

19.3. Legal Penalties

Failure to comply with OBD2 regulations can result in legal penalties, such as fines and vehicle impoundment.

19.4. Consumer Protection

OBD2 compliance helps protect consumers by ensuring that vehicles meet certain standards of performance and safety.

20. Frequently Asked Questions (FAQs) About OBD2 Spec

What are some frequently asked questions about the OBD2 spec? Here are some frequently asked questions about the OBD2 spec, along with their answers.

20.1. What is an OBD2 Scanner?

An OBD2 scanner is a diagnostic tool used to read and interpret data from a vehicle’s onboard computer system, helping to identify issues and potential problems.

20.2. How Do I Know If My Car Is OBD2 Compliant?

Most cars manufactured after 1996 in the US are OBD2 compliant. Check your vehicle’s documentation or look for the OBD2 port, typically located under the dashboard.

20.3. Can I Use an OBD2 Scanner on Any Car?

While OBD2 is a standardized protocol, compatibility can vary. Ensure the scanner supports your car’s make, model, and year for accurate diagnostics.

20.4. What Do DTCs Mean?

DTCs (Diagnostic Trouble Codes) are standardized codes that identify specific issues within a vehicle’s system, helping mechanics diagnose and repair problems efficiently.

20.5. Is It Safe to Clear DTCs Myself?

Clearing DTCs is safe, but ensure the underlying issue is resolved. Clearing codes without fixing the problem is a temporary solution.

20.6. What Is the Difference Between OBD2 and OBD1?

OBD2 is a more advanced, standardized system compared to OBD1, offering enhanced diagnostics and a wider range of data parameters.

20.7. How Often Should I Use an OBD2 Scanner?

Use an OBD2 scanner whenever you notice a warning light or suspect an issue with your vehicle. Regular checks can help prevent costly repairs.

20.8. Do Electric Vehicles Use OBD2?

Most modern EVs do not support standard OBD2 protocols, instead relying on OEM-specific UDS communication for diagnostics.

20.9. What Are PIDs?

PIDs (Parameter IDs) are identifiers for specific data parameters that can be requested and read from a vehicle’s computer, providing real-time performance data.

20.10. Can OBD2 Data Help Improve Fuel Efficiency?

Yes, by monitoring data such as fuel consumption, engine speed, and throttle position, you can identify areas where fuel efficiency can be improved.

Understanding the OBD2 spec is essential for effective vehicle diagnostics and maintenance. By leveraging the OBD2 spec, you can identify potential issues early, prevent costly repairs, and optimize your vehicle’s performance. At OBD2-SCANNER.EDU.VN, we’re dedicated to providing you with the tools and knowledge you need to make the most of your vehicle’s diagnostic capabilities.

Ready to take control of your vehicle’s diagnostics? Contact us at OBD2-SCANNER.EDU.VN, located at 123 Main Street, Los Angeles, CA 90001, United States, or reach out via WhatsApp at +1 (641) 206-8880. Let us help you understand and utilize the OBD2 spec to its full potential.