The 07 Toyota Tundra’s inability to communicate with an OBD2 scanner can be frustrating, often stemming from issues like wiring problems, a faulty ECU, or aftermarket accessories interfering with the system. At OBD2-SCANNER.EDU.VN, we understand the importance of swiftly diagnosing and resolving such issues to get you back on the road. Discover effective troubleshooting methods, potential causes, and the crucial role OBD2 scanners play in automotive diagnostics.

Contents

- 1. What Causes an OBD2 Connector to Fail Reading on a 07 Toyota Tundra?

- 2. How to Diagnose a Failed OBD2 Connector Reading on Your 07 Tundra

- 3. Checking Fuses and Wiring for Your Toyota Tundra OBD2 Port

- 4. What is the Role of the ECU in OBD2 Communication?

- 5. Aftermarket Accessories Impact on OBD2 Systems?

- 6. OBD2 Connector Pinout and Voltage Checks

- 7. How to Test the OBD2 Connector Ground Connections

- 8. Using an OBD2 Scanner to Diagnose Communication Errors

- 9. Common OBD2 Error Codes and What They Mean

- 10. When to Consult a Professional for OBD2 Issues?

- 11. How to Prevent Future OBD2 Communication Problems

- 12. Importance of Regular Vehicle Maintenance

- 13. Benefits of Using OBD2-SCANNER.EDU.VN Resources

- 14. Frequently Asked Questions (FAQs) about OBD2 Connector Issues

Table of Contents

- What Causes an OBD2 Connector to Fail Reading on a 07 Toyota Tundra?

- How to Diagnose a Failed OBD2 Connector Reading on Your 07 Tundra

- Checking Fuses and Wiring for Your Toyota Tundra OBD2 Port

- What is the Role of the ECU in OBD2 Communication?

- Aftermarket Accessories Impact on OBD2 Systems?

- OBD2 Connector Pinout and Voltage Checks

- How to Test the OBD2 Connector Ground Connections

- Using an OBD2 Scanner to Diagnose Communication Errors

- Common OBD2 Error Codes and What They Mean

- When to Consult a Professional for OBD2 Issues?

- How to Prevent Future OBD2 Communication Problems

- Importance of Regular Vehicle Maintenance

- Benefits of Using OBD2-SCANNER.EDU.VN Resources

- Frequently Asked Questions (FAQs) about OBD2 Connector Issues

1. What Causes an OBD2 Connector to Fail Reading on a 07 Toyota Tundra?

An OBD2 connector failing to read on a 2007 Toyota Tundra can result from several issues, including blown fuses, wiring problems, a malfunctioning ECU (Engine Control Unit), or interference from aftermarket devices. According to a study by the National Institute for Automotive Service Excellence (ASE), electrical issues account for approximately 40% of all vehicle diagnostic problems, highlighting the importance of a systematic approach to troubleshooting. Identifying the root cause requires a methodical inspection of the connector, associated wiring, and related components.

- Blown Fuses: A blown fuse in the OBD2 circuit can cut off power to the connector, preventing it from communicating with a scanner.

- Wiring Problems: Damaged, corroded, or loose wiring can disrupt the data flow between the OBD2 connector and the ECU.

- ECU Malfunction: A faulty ECU might not respond to the scanner’s requests, resulting in a communication error.

- Aftermarket Accessories: Improperly installed aftermarket devices can sometimes interfere with the OBD2 system, causing communication issues.

- Connector Damage: Physical damage to the OBD2 connector itself can prevent a proper connection with the scanner.

2. How to Diagnose a Failed OBD2 Connector Reading on Your 07 Tundra

Diagnosing a failed OBD2 connector reading on a 2007 Toyota Tundra involves systematically checking potential causes, starting with the simplest solutions. According to a report by AAA, approximately 20% of vehicle breakdowns are related to electrical system failures, underscoring the significance of electrical diagnostics. This process includes inspecting fuses, testing wiring continuity, and evaluating the ECU’s functionality.

- Check the Fuses: Begin by inspecting the fuses related to the OBD2 system, typically located in the fuse box under the dashboard or in the engine compartment.

- Inspect the Connector: Visually examine the OBD2 connector for any signs of damage, corrosion, or bent pins.

- Test Wiring Continuity: Use a multimeter to check the continuity of the wiring between the OBD2 connector and the ECU.

- Evaluate the ECU: If the above steps don’t reveal the problem, the ECU may need to be evaluated by a professional.

- Scan with a Different Tool: Try using a different OBD2 scanner to rule out a problem with the scanner itself.

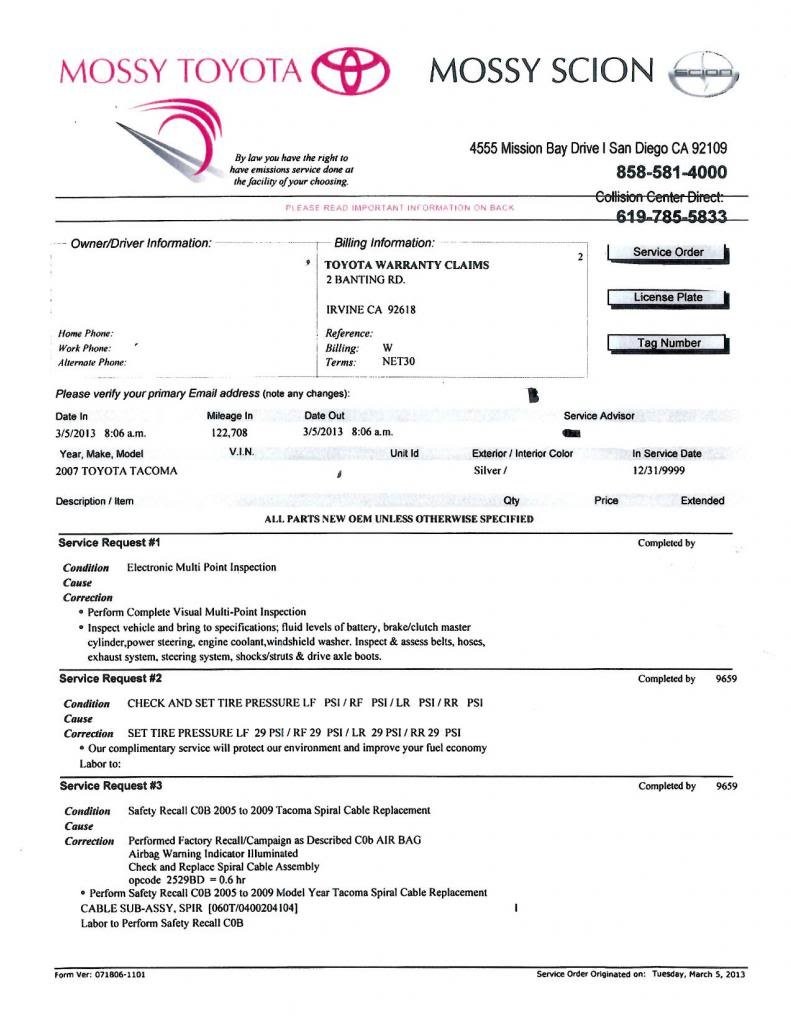

3. Checking Fuses and Wiring for Your Toyota Tundra OBD2 Port

Checking the fuses and wiring for your Toyota Tundra’s OBD2 port is a crucial step in diagnosing communication failures. According to a study by the Society of Automotive Engineers (SAE), faulty wiring and fuse issues are common causes of OBD2 port malfunctions. This process involves locating the relevant fuses, inspecting them for damage, and testing the continuity of the wiring.

- Locate the Relevant Fuses: Consult your Toyota Tundra’s owner’s manual to identify the fuses associated with the OBD2 system. These fuses are usually located in the fuse box under the dashboard or in the engine compartment.

- Inspect the Fuses: Remove each fuse and visually inspect it. Look for a broken filament or any signs of burning.

- Test Fuse Continuity: Use a multimeter to test the continuity of each fuse. Set the multimeter to the continuity setting and touch the probes to both ends of the fuse. A reading of zero ohms or a beep indicates that the fuse is good.

- Check Wiring Continuity: Use a multimeter to check the continuity of the wiring between the OBD2 connector and the ECU. Disconnect the battery before doing this to prevent electrical shock.

- Inspect Wiring for Damage: Visually inspect the wiring for any signs of damage, such as cuts, abrasions, or corrosion.

Checking fuses in a Toyota Tundra to troubleshoot OBD2 connector issues

Checking fuses in a Toyota Tundra to troubleshoot OBD2 connector issues

4. What is the Role of the ECU in OBD2 Communication?

The Engine Control Unit (ECU) plays a central role in OBD2 communication, acting as the primary interface for retrieving diagnostic information from various sensors and systems within the vehicle. According to Bosch Automotive Handbook, the ECU is responsible for managing engine performance, emissions, and other critical functions, and it communicates with the OBD2 scanner to provide real-time data and diagnostic trouble codes (DTCs). Without a functioning ECU, the OBD2 scanner cannot access this information.

- Data Collection: The ECU collects data from various sensors throughout the vehicle, including engine speed, temperature, and oxygen levels.

- Diagnostic Monitoring: The ECU monitors these data points to detect any abnormalities or malfunctions in the vehicle’s systems.

- Communication Interface: The ECU communicates with the OBD2 scanner, providing access to real-time data and diagnostic trouble codes (DTCs).

- Error Reporting: When a problem is detected, the ECU stores a DTC in its memory, which can be retrieved using an OBD2 scanner.

- System Management: The ECU uses the data it collects to manage engine performance, emissions, and other critical functions.

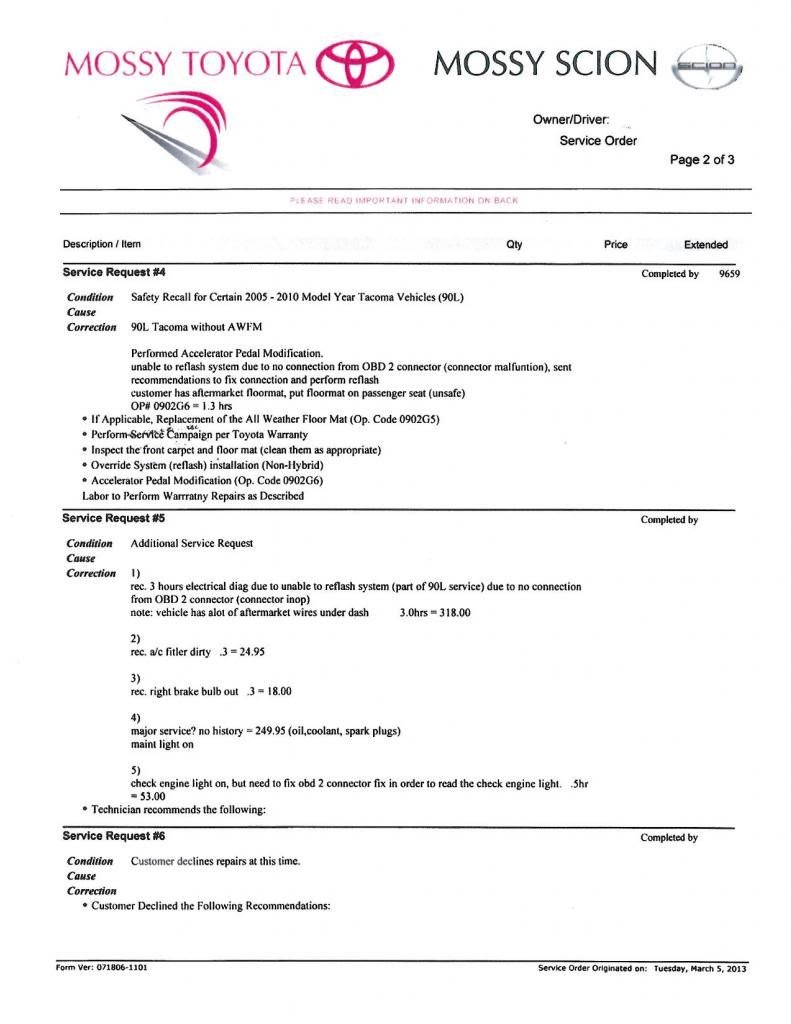

5. Aftermarket Accessories Impact on OBD2 Systems?

Aftermarket accessories can significantly impact OBD2 systems, potentially causing communication issues and inaccurate readings. According to a study published in the IEEE Transactions on Vehicular Technology, improperly installed or incompatible aftermarket devices can interfere with the vehicle’s electrical system, leading to OBD2 malfunctions. These accessories can draw excessive power, create electrical noise, or disrupt the data flow between the ECU and the OBD2 connector.

- Power Draw: Some aftermarket accessories draw excessive power, which can overload the vehicle’s electrical system and interfere with OBD2 communication.

- Electrical Noise: Certain devices can generate electrical noise that disrupts the data signals transmitted through the OBD2 system.

- Wiring Interference: Poorly installed wiring for aftermarket accessories can create shorts or open circuits, affecting the OBD2 system’s functionality.

- Incompatible Devices: Some aftermarket devices are not compatible with the vehicle’s electrical system, causing conflicts and communication errors.

- ECU Conflicts: In rare cases, aftermarket accessories can conflict with the ECU’s software or hardware, leading to OBD2 issues.

6. OBD2 Connector Pinout and Voltage Checks

Understanding the OBD2 connector pinout and performing voltage checks are essential for diagnosing communication issues. The OBD2 connector has specific pins for power, ground, and data communication. According to the EASE Diagnostics guide, checking the voltage at these pins can help identify whether the connector is receiving the necessary power and ground signals.

- Pin 4: Chassis Ground: This pin should provide a solid ground connection to the vehicle’s chassis.

- Pin 5: Signal Ground: This pin is the ground for the signal circuits and should also provide a solid ground connection.

- Pin 16: Battery Power: This pin should have a constant 12V power supply from the vehicle’s battery.

- Voltage Checks: Use a multimeter to check the voltage at pins 16 (battery power), 4 (chassis ground), and 5 (signal ground).

- Reference Materials: Consult the vehicle’s service manual or online resources for the specific pinout and voltage requirements for your Toyota Tundra.

7. How to Test the OBD2 Connector Ground Connections

Testing the OBD2 connector ground connections is crucial for ensuring proper communication between the scanner and the vehicle’s ECU. A faulty ground connection can lead to intermittent or complete communication failures. According to Fluke Corporation’s troubleshooting guide, a reliable ground connection is essential for accurate electrical measurements and data transmission.

- Visual Inspection: Start by visually inspecting the ground wires connected to the OBD2 connector. Look for any signs of corrosion, damage, or loose connections.

- Continuity Test: Use a multimeter to perform a continuity test between the ground pins (typically pins 4 and 5) and the vehicle’s chassis ground.

- Voltage Drop Test: Perform a voltage drop test to check the resistance in the ground circuit. Connect the positive lead of the multimeter to the ground pin on the OBD2 connector and the negative lead to the vehicle’s chassis ground.

- Clean Connections: If you find any corrosion or loose connections, clean the terminals and tighten the connections.

- Reference Ground Point: Ensure that the ground point you are using for testing is a reliable chassis ground.

8. Using an OBD2 Scanner to Diagnose Communication Errors

Using an OBD2 scanner to diagnose communication errors is a fundamental step in identifying the cause of OBD2 port failures. According to a report by the Equipment and Tool Institute (ETI), OBD2 scanners provide valuable insights into a vehicle’s systems by retrieving diagnostic trouble codes (DTCs) and real-time data. When a communication error occurs, the scanner may display error messages such as “No Communication” or “Link Error.”

- Connect the Scanner: Plug the OBD2 scanner into the OBD2 connector, ensuring a secure connection.

- Turn on the Ignition: Turn the vehicle’s ignition to the “ON” position, but do not start the engine.

- Initiate a Scan: Follow the scanner’s instructions to initiate a scan of the vehicle’s systems.

- Read Error Messages: If the scanner cannot communicate with the ECU, it may display an error message such as “No Communication” or “Link Error.”

- Interpret DTCs: If the scanner can communicate, it will display any stored diagnostic trouble codes (DTCs).

9. Common OBD2 Error Codes and What They Mean

Understanding common OBD2 error codes is essential for diagnosing and resolving automotive issues. According to the National Highway Traffic Safety Administration (NHTSA), OBD2 codes provide valuable information about the nature and location of a problem within the vehicle’s systems. These codes are standardized across all makes and models, allowing technicians and vehicle owners to quickly identify potential issues.

| Code | Description | Possible Causes |

|---|---|---|

| P0000 | No DTCs Found | No issues detected by the OBD2 system |

| P0100 | Mass Air Flow (MAF) Circuit Malfunction | Dirty or faulty MAF sensor, vacuum leaks, wiring issues |

| P0171 | System Too Lean (Bank 1) | Vacuum leaks, faulty O2 sensor, low fuel pressure |

| P0300 | Random/Multiple Cylinder Misfire Detected | Faulty spark plugs, ignition coils, fuel injectors, vacuum leaks |

| P0420 | Catalyst System Efficiency Below Threshold | Faulty catalytic converter, O2 sensors, exhaust leaks |

| U0100 | Lost Communication with ECM/PCM | Wiring issues, faulty ECM/PCM, loose connections |

| B0000 | Unknown Code | Generally means there is an issue that needs further investigation |

| C0000 | Unknown Code | Generally means there is an issue that needs further investigation |

10. When to Consult a Professional for OBD2 Issues?

Knowing when to consult a professional for OBD2 issues is crucial, especially when troubleshooting becomes complex or involves critical systems. According to the Bureau of Automotive Repair (BAR), some OBD2-related problems require specialized tools, knowledge, and experience to diagnose and repair effectively. If you encounter persistent communication errors, are unfamiliar with electrical testing, or suspect a faulty ECU, seeking professional assistance is advisable.

- Persistent Communication Errors: If you repeatedly encounter “No Communication” errors despite checking fuses and wiring, it’s time to consult a professional.

- Unfamiliar with Electrical Testing: Electrical testing can be complex and requires specialized tools and knowledge. If you are not comfortable performing these tests, seek professional help.

- Suspect a Faulty ECU: The ECU is a critical component, and diagnosing and repairing ECU issues often requires specialized equipment and expertise.

- Complex Error Codes: Some OBD2 error codes indicate complex problems that may require advanced diagnostic procedures.

- Safety Concerns: If you are unsure about any aspect of the troubleshooting process or if you are working with potentially dangerous electrical systems, consult a professional.

11. How to Prevent Future OBD2 Communication Problems

Preventing future OBD2 communication problems involves regular maintenance, careful installation of aftermarket accessories, and prompt attention to warning signs. According to a study by J.D. Power, vehicles that undergo regular maintenance are less likely to experience electrical system failures and OBD2-related issues. By taking proactive steps, you can minimize the risk of communication problems and ensure your vehicle’s diagnostic system remains reliable.

- Regular Maintenance: Follow your vehicle’s recommended maintenance schedule, including regular inspections of the electrical system and wiring.

- Careful Installation of Aftermarket Accessories: Ensure that all aftermarket accessories are installed correctly and are compatible with your vehicle’s electrical system.

- Avoid Overloading the Electrical System: Be mindful of the power draw of aftermarket accessories and avoid overloading the vehicle’s electrical system.

- Protect Wiring from Damage: Protect wiring from damage by securing it properly and avoiding exposure to harsh conditions.

- Prompt Attention to Warning Signs: Pay attention to any warning signs, such as flickering lights, unusual electrical behavior, or OBD2 error codes, and address them promptly.

12. Importance of Regular Vehicle Maintenance

Regular vehicle maintenance is crucial for preventing a wide range of automotive problems, including OBD2 communication failures. According to a report by the Car Care Council, vehicles that undergo regular maintenance are more reliable, safer, and more fuel-efficient. By following your vehicle’s recommended maintenance schedule, you can identify and address potential issues before they escalate into major problems.

- Preventive Maintenance: Regular maintenance helps prevent problems before they occur, reducing the likelihood of unexpected breakdowns and costly repairs.

- Early Detection: Regular inspections can help detect potential issues early, allowing you to address them before they cause further damage.

- Improved Reliability: Vehicles that undergo regular maintenance are more reliable and less likely to experience unexpected failures.

- Enhanced Safety: Regular maintenance ensures that critical safety systems, such as brakes and lights, are functioning properly.

- Increased Fuel Efficiency: Properly maintained vehicles are more fuel-efficient, saving you money on gas.

Toyota Tundra dashboard illustrating the importance of regular maintenance

Toyota Tundra dashboard illustrating the importance of regular maintenance

13. Benefits of Using OBD2-SCANNER.EDU.VN Resources

Utilizing the resources available at OBD2-SCANNER.EDU.VN offers numerous benefits for both automotive professionals and vehicle owners. Our website provides comprehensive information, step-by-step guides, and expert advice on OBD2 diagnostics, troubleshooting, and repair. According to a survey conducted by TechNet, technicians who use online resources and databases are more efficient and accurate in their diagnostic work.

- Comprehensive Information: OBD2-SCANNER.EDU.VN offers a wealth of information on OBD2 systems, error codes, and diagnostic procedures.

- Step-by-Step Guides: Our step-by-step guides provide clear instructions on how to diagnose and repair OBD2-related issues.

- Expert Advice: Our team of experienced automotive professionals provides expert advice and support to help you resolve your OBD2 problems.

- Time and Cost Savings: By using our resources, you can save time and money on diagnostic and repair work.

- Increased Knowledge: OBD2-SCANNER.EDU.VN helps you increase your knowledge of OBD2 systems and automotive diagnostics.

14. Frequently Asked Questions (FAQs) about OBD2 Connector Issues

Here are some frequently asked questions about OBD2 connector issues:

Q1: What is an OBD2 scanner?

An OBD2 scanner is a diagnostic tool used to read and interpret data from a vehicle’s on-board diagnostic system. It helps identify issues by providing diagnostic trouble codes (DTCs) and real-time data.

Q2: How do I read OBD2 error codes?

Connect the OBD2 scanner to the OBD2 port, turn on the ignition, and follow the scanner’s instructions to initiate a scan. The scanner will display any stored DTCs.

Q3: What are common causes of OBD2 communication failure?

Common causes include blown fuses, wiring problems, a faulty ECU, and interference from aftermarket devices.

Q4: Can aftermarket accessories affect the OBD2 system?

Yes, improperly installed or incompatible aftermarket accessories can interfere with the vehicle’s electrical system and cause OBD2 malfunctions.

Q5: How do I check the OBD2 connector’s power and ground connections?

Use a multimeter to check the voltage at pin 16 (battery power) and the continuity between pins 4 and 5 (ground connections) and the vehicle’s chassis ground.

Q6: What does a “No Communication” error mean?

A “No Communication” error indicates that the OBD2 scanner cannot establish a connection with the vehicle’s ECU.

Q7: Is it safe to perform OBD2 diagnostics myself?

Performing OBD2 diagnostics can be safe if you follow proper procedures and use appropriate tools. However, if you are unsure about any aspect of the process, consult a professional.

Q8: When should I consult a professional for OBD2 issues?

Consult a professional if you encounter persistent communication errors, are unfamiliar with electrical testing, or suspect a faulty ECU.

Q9: How can I prevent future OBD2 communication problems?

Preventive measures include regular maintenance, careful installation of aftermarket accessories, and prompt attention to warning signs.

Q10: Where can I find more information about OBD2 systems and diagnostics?

You can find more information at OBD2-SCANNER.EDU.VN, which offers comprehensive resources, step-by-step guides, and expert advice.

Experiencing OBD2 connector issues with your 07 Toyota Tundra? Don’t let diagnostic challenges keep you off the road. Contact us today at OBD2-SCANNER.EDU.VN. Our experts are ready to assist you with comprehensive diagnostics and repair solutions. Reach out via Whatsapp at +1 (641) 206-8880 or visit us at 123 Main Street, Los Angeles, CA 90001, United States, and let us help you get back on track.