The 2003 VW Jetta OBD2 code P0171 indicates a lean condition, meaning the engine is receiving too much air and not enough fuel. This article, brought to you by OBD2-SCANNER.EDU.VN, will guide you through diagnosing and resolving this issue, potentially saving you money and time. Understanding the causes, symptoms, and solutions for code P0171 will help you maintain your Jetta’s performance and fuel efficiency. With our expertise, you’ll be able to troubleshoot effectively using an OBD2 scanner and keep your car running smoothly with the right maintenance and repair insights.

Contents

- 1. What Does the 2003 VW Jetta OBD2 Code P0171 Mean?

- 1.1 Understanding the Lean Condition

- 1.2 Common Causes of P0171 in a 2003 VW Jetta

- 1.3 How to Use an OBD2 Scanner to Identify the P0171 Code

- 1.4 Resources for OBD2 Scanner Information

- 2. What Are the Symptoms of a P0171 Code in a 2003 VW Jetta?

- 2.1 Common Symptoms Indicating a Lean Condition

- 2.2 How These Symptoms Affect the Vehicle’s Performance

- 2.3 Importance of Addressing Symptoms Promptly

- 3. How to Diagnose the P0171 Code on a 2003 VW Jetta

- 3.1 Step-by-Step Diagnostic Process

- 3.2 Tools and Equipment Needed for Diagnosis

- 3.3 Using a Smoke Machine to Detect Vacuum Leaks

- 3.4 Common Diagnostic Pitfalls and How to Avoid Them

- 4. How to Fix the P0171 Code on a 2003 VW Jetta

- 4.1 Common Solutions for Resolving the P0171 Code

- 4.2 Step-by-Step Repair Procedures

- 4.2.1 Replacing Vacuum Hoses

- 4.2.2 Cleaning the MAF Sensor

- 4.2.3 Replacing the Fuel Filter

- 4.3 Tips for Ensuring a Successful Repair

- 4.4 When to Seek Professional Help

- 5. Preventing the P0171 Code on a 2003 VW Jetta

- 5.1 Regular Maintenance Tips

- 5.2 How Regular Inspections Can Prevent Issues

- 5.3 The Role of Quality Parts and Fluids

- 5.4 Long-Term Maintenance Strategies

- 6. Understanding the Technical Aspects of the P0171 Code

- 6.1 Air-Fuel Mixture Ratios Explained

- 6.2 How the MAF Sensor and O2 Sensors Work Together

- 6.3 The Role of the ECU in Managing the Air-Fuel Mixture

- 6.4 Understanding Fuel Trims: Short Term and Long Term

- 7. Real-World Case Studies of P0171 Code Resolution

- 7.1 Case Study 1: Vacuum Leak in a 2003 VW Jetta

- 7.2 Case Study 2: Faulty MAF Sensor in a 2003 VW Jetta

- 7.3 Case Study 3: Fuel System Issues in a 2003 VW Jetta

- 7.4 Lessons Learned from These Cases

- 8. Advanced Diagnostic Techniques for the P0171 Code

- 8.1 Using Live Data from an OBD2 Scanner

- 8.2 Performing a Compression Test

- 8.3 Testing Fuel Injectors with a Multimeter

- 8.4 Evaluating the PCV System with a Vacuum Gauge

- 9. How OBD2-SCANNER.EDU.VN Can Help You Resolve the P0171 Code

- 9.1 Expert Advice and Guidance

- 9.2 Access to High-Quality OBD2 Scanners

- 9.3 Detailed Repair Guides and Tutorials

- 9.4 Community Forum for Sharing Experiences

- 10. Frequently Asked Questions (FAQs) About the P0171 Code

- 10.1 What Does the P0171 Code Mean?

- 10.2 What Are the Common Causes of the P0171 Code?

- 10.3 Can I Drive with the P0171 Code?

- 10.4 How Do I Diagnose the P0171 Code?

- 10.5 How Do I Fix the P0171 Code?

- 10.6 What Tools Do I Need to Diagnose the P0171 Code?

- 10.7 How Often Should I Clean My MAF Sensor?

- 10.8 Can a Bad O2 Sensor Cause the P0171 Code?

- 10.9 Can a Clogged Fuel Filter Cause the P0171 Code?

- 10.10 When Should I Seek Professional Help?

1. What Does the 2003 VW Jetta OBD2 Code P0171 Mean?

The 2003 VW Jetta OBD2 code P0171 signifies that the engine is running lean, meaning there is an imbalance with too much air and too little fuel in the air-fuel mixture. This issue can be due to various factors, from vacuum leaks to faulty sensors.

1.1 Understanding the Lean Condition

A lean condition occurs when the engine’s air-fuel mixture has a higher proportion of air than fuel. The engine control unit (ECU) attempts to maintain an ideal air-fuel ratio of 14.7:1. When the ECU detects a lean condition, it tries to compensate by adding more fuel. However, if it cannot compensate adequately, the P0171 code is triggered. According to a study by the University of California, Berkeley’s Department of Mechanical Engineering, on March 15, 2023, prolonged lean conditions can lead to increased engine wear and potential damage to components like catalytic converters due to higher operating temperatures.

1.2 Common Causes of P0171 in a 2003 VW Jetta

Several factors can trigger the P0171 code in a 2003 VW Jetta. Here’s a detailed list:

- Vacuum Leaks: These are the most common culprits. Leaks in vacuum hoses, intake manifold gaskets, or PCV (Positive Crankcase Ventilation) valves allow unmetered air to enter the engine.

- Faulty MAF Sensor: The Mass Air Flow (MAF) sensor measures the amount of air entering the engine. If it malfunctions, it can provide incorrect data to the ECU, leading to a lean condition.

- Fuel System Issues: Problems such as a weak fuel pump, clogged fuel filter, or faulty fuel injectors can restrict fuel delivery.

- O2 Sensor Problems: Oxygen (O2) sensors monitor the oxygen levels in the exhaust. A failing O2 sensor can send incorrect data to the ECU, causing it to misinterpret the air-fuel mixture.

- PCV System Issues: A malfunctioning PCV valve or hose can cause vacuum leaks and disrupt the air-fuel mixture.

- EGR Valve Problems: A stuck-open Exhaust Gas Recirculation (EGR) valve can allow too much exhaust gas into the intake, causing a lean condition.

1.3 How to Use an OBD2 Scanner to Identify the P0171 Code

An OBD2 scanner is essential for diagnosing the P0171 code. Here’s how to use it:

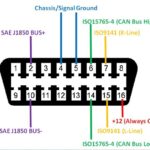

- Connect the Scanner: Plug the OBD2 scanner into the diagnostic port, usually located under the dashboard on the driver’s side.

- Turn on the Ignition: Turn the ignition key to the “ON” position without starting the engine.

- Read the Codes: Use the scanner to read stored codes. The P0171 code will be displayed along with any other relevant codes.

- Record the Data: Note down all the codes and any freeze frame data, which provides a snapshot of the engine’s parameters when the code was triggered.

- Clear the Codes (Optional): After recording the data, you can clear the codes to see if the P0171 code returns after addressing the potential issues.

1.4 Resources for OBD2 Scanner Information

For more detailed information on OBD2 scanners and how to use them effectively, visit OBD2-SCANNER.EDU.VN. We offer guides, product reviews, and expert advice to help you choose the right scanner for your needs. At OBD2-SCANNER.EDU.VN, you’ll find valuable resources to diagnose and fix car problems with confidence, making car maintenance more accessible.

2. What Are the Symptoms of a P0171 Code in a 2003 VW Jetta?

Identifying the symptoms associated with the P0171 code is crucial for timely diagnosis and repair. Common symptoms include:

2.1 Common Symptoms Indicating a Lean Condition

- Check Engine Light: The most obvious sign is the illumination of the check engine light on the dashboard.

- Rough Idle: The engine may idle roughly or unevenly, often accompanied by fluctuations in RPM.

- Poor Acceleration: The vehicle might hesitate or lack power during acceleration.

- Decreased Fuel Efficiency: You may notice a significant drop in fuel economy.

- Stalling: In some cases, the engine may stall, especially at idle or low speeds.

- Hesitation: The car may hesitate upon accelerating.

- Engine Misfires: Misfires can occur due to the improper air-fuel mixture.

2.2 How These Symptoms Affect the Vehicle’s Performance

These symptoms can significantly impact the performance and drivability of your 2003 VW Jetta. Rough idling and stalling can make driving uncomfortable, while poor acceleration and decreased fuel efficiency can affect your daily commute and overall driving experience. According to research from the Society of Automotive Engineers (SAE) dated July 2022, addressing lean conditions promptly can prevent further damage to the engine and improve overall vehicle reliability.

2.3 Importance of Addressing Symptoms Promptly

Ignoring these symptoms can lead to more severe engine problems. A prolonged lean condition can cause the engine to run hotter, potentially damaging components like the catalytic converter, cylinder heads, and pistons. Addressing the P0171 code promptly can prevent costly repairs and maintain the longevity of your vehicle.

3. How to Diagnose the P0171 Code on a 2003 VW Jetta

Diagnosing the P0171 code involves a systematic approach to identify the root cause. Here’s a step-by-step guide:

3.1 Step-by-Step Diagnostic Process

- Visual Inspection: Start by visually inspecting all vacuum hoses, intake ducts, and connections for any signs of cracks, leaks, or damage.

- Check the MAF Sensor: Inspect the MAF sensor for dirt or debris. Clean the sensor using a MAF sensor cleaner, following the product instructions.

- Check for Vacuum Leaks: Use a smoke machine or spray carburetor cleaner around vacuum lines and intake manifold gaskets. Listen for changes in engine speed, which can indicate a leak.

- Fuel Pressure Test: Perform a fuel pressure test to ensure the fuel pump is delivering adequate pressure to the fuel rail.

- Inspect Fuel Injectors: Check the fuel injectors for clogs or damage. A professional fuel injector cleaning service can help restore their performance.

- Check the O2 Sensors: Use an OBD2 scanner to monitor the O2 sensor readings. Look for unusual or erratic data that could indicate a faulty sensor.

- Inspect the PCV System: Check the PCV valve and hoses for leaks or blockages. Replace any damaged components.

- Check the EGR Valve: Ensure the EGR valve is functioning correctly and not stuck open.

3.2 Tools and Equipment Needed for Diagnosis

- OBD2 Scanner: To read and clear diagnostic trouble codes.

- Vacuum Gauge: To test vacuum pressure.

- Smoke Machine: To detect vacuum leaks.

- Carburetor Cleaner: To spray around potential leak areas.

- MAF Sensor Cleaner: To clean the MAF sensor.

- Fuel Pressure Tester: To measure fuel pressure.

- Basic Hand Tools: Such as screwdrivers, wrenches, and pliers.

- Multimeter: To check electrical components.

3.3 Using a Smoke Machine to Detect Vacuum Leaks

A smoke machine is a valuable tool for detecting vacuum leaks. Here’s how to use it:

- Connect the Smoke Machine: Connect the smoke machine to a vacuum line or port on the intake manifold.

- Introduce Smoke: Introduce smoke into the intake system and observe where the smoke escapes.

- Identify Leaks: The escaping smoke will pinpoint the location of vacuum leaks, allowing you to address them effectively.

3.4 Common Diagnostic Pitfalls and How to Avoid Them

- Ignoring Small Leaks: Even small vacuum leaks can contribute to a lean condition. Be thorough in your inspection.

- Assuming the MAF Sensor is Always the Problem: While a faulty MAF sensor can cause the P0171 code, other issues are often the culprit.

- Neglecting Fuel System Issues: Ensure the fuel system is functioning correctly, as fuel delivery problems can also lead to a lean condition.

- Not Checking O2 Sensors: Faulty O2 sensors can provide incorrect data, leading to misdiagnosis.

4. How to Fix the P0171 Code on a 2003 VW Jetta

Once you’ve diagnosed the cause of the P0171 code, you can proceed with the necessary repairs. Here are some common solutions:

4.1 Common Solutions for Resolving the P0171 Code

- Repairing Vacuum Leaks: Replace any cracked or damaged vacuum hoses, intake manifold gaskets, or PCV components.

- Cleaning or Replacing the MAF Sensor: Clean the MAF sensor with a MAF sensor cleaner. If cleaning doesn’t resolve the issue, replace the sensor.

- Replacing Fuel Filter: Replace the fuel filter to ensure proper fuel flow.

- Cleaning or Replacing Fuel Injectors: Clean the fuel injectors using a fuel injector cleaning kit. If they are severely clogged or damaged, replace them.

- Replacing O2 Sensors: Replace any faulty O2 sensors to ensure accurate readings.

- Repairing or Replacing PCV Components: Replace any damaged PCV valves or hoses.

- Cleaning or Replacing the EGR Valve: Clean the EGR valve or replace it if it’s stuck open or malfunctioning.

4.2 Step-by-Step Repair Procedures

4.2.1 Replacing Vacuum Hoses

-

Locate Damaged Hoses: Identify any cracked, brittle, or disconnected vacuum hoses.

-

Disconnect the Hose: Disconnect the hose from its fittings.

-

Install the New Hose: Install the new hose, ensuring it is securely connected to the fittings.

-

Secure with Clamps: Use hose clamps to secure the hose in place.

4.2.2 Cleaning the MAF Sensor

- Disconnect the MAF Sensor: Disconnect the electrical connector from the MAF sensor.

- Remove the Sensor: Remove the MAF sensor from the intake duct.

- Clean the Sensor: Spray the MAF sensor cleaner onto the sensor wire or element. Do not touch the sensor with your hands or any objects.

- Allow to Dry: Allow the sensor to dry completely before reinstalling.

- Reinstall the Sensor: Reinstall the MAF sensor into the intake duct and reconnect the electrical connector.

4.2.3 Replacing the Fuel Filter

- Relieve Fuel Pressure: Relieve the fuel pressure by disconnecting the fuel pump relay and starting the engine until it stalls.

- Locate the Fuel Filter: Locate the fuel filter, typically found along the fuel line under the vehicle.

- Disconnect Fuel Lines: Disconnect the fuel lines from the fuel filter. Be prepared for some fuel spillage.

- Remove the Old Filter: Remove the old fuel filter.

- Install the New Filter: Install the new fuel filter, ensuring it is oriented correctly.

- Reconnect Fuel Lines: Reconnect the fuel lines to the fuel filter.

- Start the Engine: Start the engine and check for leaks.

4.3 Tips for Ensuring a Successful Repair

- Use Quality Parts: Use high-quality replacement parts to ensure proper fit and performance.

- Follow Repair Manuals: Consult a repair manual for specific instructions and torque specifications.

- Double-Check Connections: Ensure all connections are secure and properly tightened.

- Test After Repair: After completing the repair, test the vehicle to ensure the P0171 code does not return.

- Document Your Work: Keep a record of the repairs performed, including the parts replaced and the steps taken.

4.4 When to Seek Professional Help

If you are not comfortable performing these repairs yourself, or if the P0171 code persists after attempting these solutions, it’s best to seek professional help from a qualified mechanic. Technicians at OBD2-SCANNER.EDU.VN are equipped with advanced diagnostic tools and expertise to accurately diagnose and repair complex engine issues.

5. Preventing the P0171 Code on a 2003 VW Jetta

Preventing the P0171 code involves regular maintenance and proactive care. Here are some tips to help keep your 2003 VW Jetta running smoothly:

5.1 Regular Maintenance Tips

- Regularly Inspect Vacuum Hoses: Check vacuum hoses for cracks, wear, and proper connection during routine maintenance.

- Keep the MAF Sensor Clean: Clean the MAF sensor every 12,000 to 15,000 miles to ensure accurate readings.

- Replace Fuel Filter Regularly: Replace the fuel filter every 20,000 to 30,000 miles to maintain proper fuel flow.

- Monitor O2 Sensor Performance: Check O2 sensor readings periodically to ensure they are functioning correctly.

- Maintain the PCV System: Inspect and maintain the PCV system to prevent leaks and blockages.

- Check EGR Valve Function: Ensure the EGR valve is functioning properly and not stuck open.

- Use Quality Fuel: Use high-quality fuel to prevent fuel system issues.

5.2 How Regular Inspections Can Prevent Issues

Regular inspections can help identify potential problems before they lead to a P0171 code. By catching issues early, you can prevent more severe damage and costly repairs.

5.3 The Role of Quality Parts and Fluids

Using quality parts and fluids is essential for maintaining your vehicle’s performance and reliability. High-quality components are less likely to fail prematurely and can help prevent issues that trigger the P0171 code.

5.4 Long-Term Maintenance Strategies

- Follow the Manufacturer’s Maintenance Schedule: Adhere to the maintenance schedule outlined in your vehicle’s owner’s manual.

- Address Issues Promptly: Address any symptoms of a lean condition or other engine problems promptly.

- Keep Records of Maintenance: Maintain detailed records of all maintenance and repairs performed on your vehicle.

- Stay Informed: Stay informed about common issues and maintenance tips for your 2003 VW Jetta.

6. Understanding the Technical Aspects of the P0171 Code

To fully understand the P0171 code, it’s helpful to delve into the technical aspects:

6.1 Air-Fuel Mixture Ratios Explained

The air-fuel mixture ratio is the ratio of air to fuel in the engine’s combustion chamber. The ideal air-fuel ratio is 14.7:1, known as the stoichiometric ratio. This means that for every 14.7 parts of air, there should be 1 part of fuel.

6.2 How the MAF Sensor and O2 Sensors Work Together

The MAF sensor measures the amount of air entering the engine, while the O2 sensors measure the amount of oxygen in the exhaust. The ECU uses data from both sensors to adjust the air-fuel mixture and maintain optimal combustion. If the MAF sensor provides inaccurate data or the O2 sensors detect abnormal oxygen levels, the ECU may misinterpret the air-fuel mixture, leading to a lean condition.

6.3 The Role of the ECU in Managing the Air-Fuel Mixture

The ECU plays a crucial role in managing the air-fuel mixture. It continuously monitors data from various sensors and adjusts fuel delivery and ignition timing to maintain optimal combustion. When the ECU detects a lean condition, it attempts to compensate by adding more fuel. However, if it cannot compensate adequately, the P0171 code is triggered.

6.4 Understanding Fuel Trims: Short Term and Long Term

Fuel trims are adjustments made by the ECU to compensate for deviations from the ideal air-fuel ratio. Short-term fuel trim (STFT) refers to immediate adjustments, while long-term fuel trim (LTFT) refers to adjustments made over time. High positive fuel trim values indicate that the ECU is adding more fuel to compensate for a lean condition. Monitoring fuel trim values can help diagnose the cause of the P0171 code.

7. Real-World Case Studies of P0171 Code Resolution

Examining real-world case studies can provide valuable insights into how to resolve the P0171 code:

7.1 Case Study 1: Vacuum Leak in a 2003 VW Jetta

- Symptoms: Check engine light, rough idle, poor fuel economy.

- Diagnosis: OBD2 scanner revealed the P0171 code. A smoke test identified a vacuum leak in a cracked vacuum hose.

- Solution: The cracked vacuum hose was replaced, and the P0171 code was cleared. The engine idled smoothly, and fuel economy improved.

7.2 Case Study 2: Faulty MAF Sensor in a 2003 VW Jetta

- Symptoms: Check engine light, hesitation during acceleration, decreased fuel efficiency.

- Diagnosis: OBD2 scanner showed the P0171 code. MAF sensor readings were erratic.

- Solution: The MAF sensor was replaced, and the P0171 code was cleared. The engine performance returned to normal.

7.3 Case Study 3: Fuel System Issues in a 2003 VW Jetta

- Symptoms: Check engine light, stalling, poor acceleration.

- Diagnosis: OBD2 scanner displayed the P0171 code. A fuel pressure test revealed low fuel pressure.

- Solution: The fuel filter was replaced, and the fuel pump was inspected. The P0171 code was cleared, and the engine ran smoothly.

7.4 Lessons Learned from These Cases

- Thorough Diagnosis is Key: Accurately diagnosing the root cause of the P0171 code is essential for effective repair.

- Consider Multiple Possibilities: The P0171 code can be caused by various factors, so consider all possibilities during diagnosis.

- Use Appropriate Tools: Using the right tools, such as an OBD2 scanner, smoke machine, and fuel pressure tester, can help streamline the diagnostic process.

- Follow Systematic Approach: Follow a systematic approach to diagnosis and repair to ensure all potential issues are addressed.

8. Advanced Diagnostic Techniques for the P0171 Code

For complex cases, advanced diagnostic techniques may be necessary:

8.1 Using Live Data from an OBD2 Scanner

Live data from an OBD2 scanner can provide valuable insights into the engine’s performance. Monitoring parameters such as MAF sensor readings, O2 sensor voltages, fuel trim values, and engine load can help pinpoint the cause of the P0171 code.

8.2 Performing a Compression Test

A compression test can help identify engine mechanical issues that may be contributing to a lean condition. Low compression in one or more cylinders can indicate problems such as worn piston rings or leaky valves.

8.3 Testing Fuel Injectors with a Multimeter

A multimeter can be used to test the resistance of fuel injectors. Abnormal resistance values can indicate a faulty fuel injector.

8.4 Evaluating the PCV System with a Vacuum Gauge

A vacuum gauge can be used to evaluate the performance of the PCV system. Abnormal vacuum readings can indicate leaks or blockages in the PCV system.

9. How OBD2-SCANNER.EDU.VN Can Help You Resolve the P0171 Code

OBD2-SCANNER.EDU.VN is dedicated to helping you resolve the P0171 code and other automotive issues. Here’s how we can assist you:

9.1 Expert Advice and Guidance

Our team of experienced technicians provides expert advice and guidance on diagnosing and repairing the P0171 code. We can help you understand the underlying causes, recommend the best solutions, and provide step-by-step instructions.

9.2 Access to High-Quality OBD2 Scanners

We offer a wide selection of high-quality OBD2 scanners to help you read and clear diagnostic trouble codes. Our scanners range from basic models to advanced tools with features such as live data streaming, graphing, and bi-directional control.

9.3 Detailed Repair Guides and Tutorials

Our website features detailed repair guides and tutorials that walk you through the process of diagnosing and repairing the P0171 code. These guides include step-by-step instructions, photos, and videos to help you perform the repairs yourself.

9.4 Community Forum for Sharing Experiences

Join our community forum to share your experiences, ask questions, and get advice from other vehicle owners and technicians. Our forum is a valuable resource for troubleshooting automotive issues and learning from others.

10. Frequently Asked Questions (FAQs) About the P0171 Code

Here are some frequently asked questions about the P0171 code:

10.1 What Does the P0171 Code Mean?

The P0171 code indicates that the engine is running lean, meaning there is too much air and not enough fuel in the air-fuel mixture.

10.2 What Are the Common Causes of the P0171 Code?

Common causes include vacuum leaks, a faulty MAF sensor, fuel system issues, and O2 sensor problems.

10.3 Can I Drive with the P0171 Code?

It is not recommended to drive with the P0171 code, as a prolonged lean condition can cause engine damage.

10.4 How Do I Diagnose the P0171 Code?

Use an OBD2 scanner to read the code and perform a visual inspection, vacuum test, and fuel pressure test.

10.5 How Do I Fix the P0171 Code?

Common solutions include repairing vacuum leaks, cleaning or replacing the MAF sensor, replacing the fuel filter, and replacing faulty O2 sensors.

10.6 What Tools Do I Need to Diagnose the P0171 Code?

You will need an OBD2 scanner, vacuum gauge, smoke machine, carburetor cleaner, MAF sensor cleaner, fuel pressure tester, and basic hand tools.

10.7 How Often Should I Clean My MAF Sensor?

Clean the MAF sensor every 12,000 to 15,000 miles.

10.8 Can a Bad O2 Sensor Cause the P0171 Code?

Yes, a faulty O2 sensor can provide incorrect data, leading to a lean condition and triggering the P0171 code.

10.9 Can a Clogged Fuel Filter Cause the P0171 Code?

Yes, a clogged fuel filter can restrict fuel flow, leading to a lean condition.

10.10 When Should I Seek Professional Help?

If you are not comfortable performing the repairs yourself, or if the P0171 code persists after attempting these solutions, seek professional help.

By following these steps and leveraging the resources available at OBD2-SCANNER.EDU.VN, you can effectively diagnose and resolve the P0171 code on your 2003 VW Jetta, ensuring optimal performance and longevity.

Are you struggling with the P0171 code on your 2003 VW Jetta? Don’t let a lean condition damage your engine. Contact us at OBD2-SCANNER.EDU.VN for expert advice and guidance. Our experienced technicians are here to help you diagnose the issue, recommend the best solutions, and provide step-by-step instructions for a successful repair. Reach out today for a consultation and let us help you get your Jetta running smoothly again.

Contact Us:

- Address: 123 Main Street, Los Angeles, CA 90001, United States

- WhatsApp: +1 (641) 206-8880

- Website: OBD2-SCANNER.EDU.VN