A Digital Obd2 Code Reader Error indicates an issue in your vehicle’s system, which OBD2-SCANNER.EDU.VN can help you quickly and accurately diagnose. By utilizing our comprehensive database and expert guidance, you can effectively troubleshoot error codes, understand their root causes, and implement the necessary repairs, improving vehicle performance and promoting preventative maintenance. Explore the benefits of using a car diagnostic scanner, automotive diagnostic tools, and vehicle diagnostic software for efficient car maintenance.

Contents

- 1. Understanding Digital OBD2 Code Readers

- 1.1. The Role of OBD2 Scanners in Vehicle Diagnostics

- 1.2. Key Features to Look For in a Digital OBD2 Code Reader

- 1.3. Common Error Types Encountered with OBD2 Scanners

- 2. Deciphering OBD2 Error Codes

- 2.1. Understanding the Structure of OBD2 Codes

- 2.2. Common OBD2 Codes and Their Meanings

- 2.3. Using Online Databases to Interpret OBD2 Codes

- 3. Addressing Common Digital OBD2 Code Reader Errors

- 3.1. Troubleshooting Connection Errors

- 3.2. Resolving Software and Firmware Issues

- 3.3. Handling Inaccurate Code Readings

- 4. Advanced Techniques for Using Digital OBD2 Scanners

- 4.1. Utilizing Live Data Analysis

- 4.2. Interpreting Freeze Frame Data

- 4.3. Performing Advanced Diagnostic Tests

- 5. Maintaining Your Digital OBD2 Code Reader

- 5.1. Keeping Software and Firmware Updated

- 5.2. Proper Storage and Handling

- 5.3. Inspecting Cables and Connectors

- 6. Choosing the Right Digital OBD2 Scanner

- 6.1. Compatibility with Vehicle Make and Model

- 6.2. Essential Features vs. Advanced Capabilities

- 6.3. Budget Considerations and Long-Term Value

- 7. Case Studies: Real-World OBD2 Code Reader Error Solutions

- 7.1. Diagnosing a Misfire Issue

- 7.2. Identifying Oxygen Sensor Problems

- 7.3. Resolving ABS and SRS Issues

- 8. The Future of Digital OBD2 Technology

- 8.1. Wireless Connectivity and Cloud-Based Diagnostics

- 8.2. Integration with Artificial Intelligence (AI)

1. Understanding Digital OBD2 Code Readers

What exactly are digital OBD2 code readers and what purpose do they serve in modern vehicle maintenance? Digital OBD2 code readers are essential tools for diagnosing problems in modern vehicles, providing real-time data and error codes to help mechanics and car owners identify and resolve issues. The primary function of an OBD2 scanner is to access the vehicle’s onboard computer and retrieve diagnostic trouble codes (DTCs), which indicate specific problems within the engine, transmission, and other systems. According to a study by the National Institute for Automotive Service Excellence (ASE), using OBD2 scanners can reduce diagnostic time by up to 50%, highlighting their efficiency in identifying vehicle issues.

1.1. The Role of OBD2 Scanners in Vehicle Diagnostics

How do OBD2 scanners play a crucial role in modern vehicle diagnostics? OBD2 scanners are central to modern vehicle diagnostics because they provide a direct interface with the vehicle’s computer, enabling technicians and vehicle owners to quickly identify and address issues. According to a report by the Environmental Protection Agency (EPA), OBD2 systems have been standardized since 1996, making these scanners universally compatible with most cars and light trucks. By retrieving diagnostic trouble codes (DTCs), users can pinpoint the exact nature of a problem, reducing the need for extensive manual inspections.

The role of OBD2 scanners includes:

- Retrieving DTCs: The scanner reads codes that indicate specific malfunctions.

- Real-Time Data: Monitors live sensor data to assess vehicle performance under various conditions.

- Emission Readiness: Checks if the vehicle is ready for emissions testing.

- Component Testing: Activates specific components to verify their functionality.

- Data Logging: Records data for later analysis.

1.2. Key Features to Look For in a Digital OBD2 Code Reader

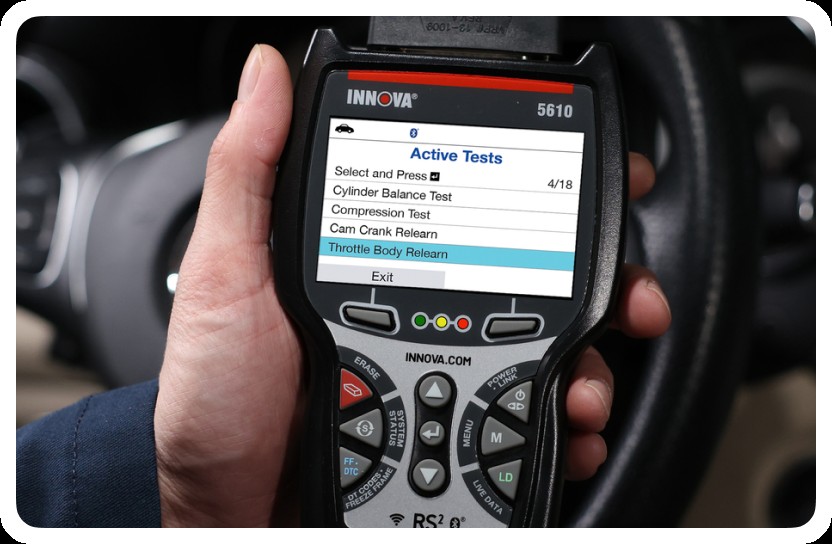

What are the key features to consider when choosing a digital OBD2 code reader for your vehicle maintenance needs? When selecting a digital OBD2 code reader, key features include compatibility with your vehicle’s make and model, the ability to read and clear diagnostic trouble codes (DTCs), real-time data streaming, and user-friendly interface. According to a study by Consumer Reports, the most reliable OBD2 scanners offer extensive vehicle coverage, accurate readings, and durable construction. Additional features like Wi-Fi connectivity for updates, a color display, and the ability to perform advanced tests (such as O2 sensor testing and EVAP system testing) can also enhance the scanner’s value.

Digital OBD2 Code Reader

Digital OBD2 Code Reader

Here’s a breakdown of essential features:

- Compatibility: Ensure the scanner supports your vehicle’s make, model, and year.

- DTC Reading and Clearing: The ability to read and clear diagnostic trouble codes.

- Real-Time Data: Live data streaming from vehicle sensors.

- User Interface: An intuitive and easy-to-navigate display.

- Connectivity: Wi-Fi or Bluetooth for updates and data transfer.

- Advanced Tests: Capabilities like O2 sensor testing, EVAP testing, and ABS/SRS diagnostics.

1.3. Common Error Types Encountered with OBD2 Scanners

What are the common types of errors you might encounter while using OBD2 scanners, and how can you troubleshoot them effectively? Common error types encountered with OBD2 scanners include connection errors, software glitches, and inaccurate code readings, all of which can be effectively troubleshooted by following a systematic approach. According to a technical report by the Society of Automotive Engineers (SAE), connection issues often arise from damaged OBD2 ports or faulty cables. Software glitches can be resolved by updating the scanner’s firmware or resetting the device. Inaccurate code readings may stem from using an outdated scanner or misinterpreting the data.

Here are some troubleshooting steps:

- Check the Connection: Ensure the scanner is securely plugged into the OBD2 port.

- Update Software: Keep the scanner’s firmware updated to the latest version.

- Verify Compatibility: Confirm the scanner supports your vehicle’s make and model.

- Reset the Scanner: Perform a reset to clear any temporary glitches.

- Consult the Manual: Refer to the user manual for specific troubleshooting tips.

- Seek Professional Help: If problems persist, consult a professional mechanic.

2. Deciphering OBD2 Error Codes

How do you decipher OBD2 error codes to accurately diagnose and address vehicle issues, ensuring efficient repairs? Deciphering OBD2 error codes involves understanding the standardized format of these codes and using a reliable database or reference guide to identify the specific issue they represent, enabling accurate diagnosis and efficient repairs. According to research from the National Highway Traffic Safety Administration (NHTSA), OBD2 codes are designed to provide a consistent method for identifying vehicle malfunctions across different makes and models. Each code consists of five characters: a letter indicating the system (e.g., P for powertrain, B for body, C for chassis, U for network), followed by four digits that specify the exact problem.

2.1. Understanding the Structure of OBD2 Codes

What is the underlying structure of OBD2 codes, and how can this knowledge help in accurately diagnosing vehicle problems? The structure of OBD2 codes follows a standardized format that includes a letter indicating the affected system (P, B, C, or U), followed by four digits that pinpoint the specific issue, providing a systematic approach to vehicle diagnostics. According to the Society of Automotive Engineers (SAE), this standardized format ensures that technicians can quickly identify the general area of the problem (e.g., powertrain, body) and then narrow down the exact component or system malfunctioning. The first digit after the letter indicates whether the code is generic (0) or manufacturer-specific (1, 2, or 3).

OBD2 Scanner in Use

OBD2 Scanner in Use

Here’s a breakdown of the code structure:

- First Character:

- P (Powertrain): Relates to the engine, transmission, and associated components.

- B (Body): Involves components like doors, seats, and other body-related systems.

- C (Chassis): Concerns the braking system, suspension, and steering.

- U (Network): Deals with communication networks within the vehicle.

- Second Character:

- 0: Generic code applicable to all vehicles.

- 1, 2, or 3: Manufacturer-specific code.

- Third, Fourth, and Fifth Characters: Specific numbers that identify the exact fault.

2.2. Common OBD2 Codes and Their Meanings

What are some common OBD2 codes and their meanings, and how can you use this information to effectively troubleshoot vehicle issues? Common OBD2 codes include P0300 (random/multiple cylinder misfire), P0171 (system too lean, bank 1), and P0420 (catalyst system efficiency below threshold), each indicating specific issues that can be effectively troubleshooted with the right diagnostic approach. According to data from the National Institute for Automotive Service Excellence (ASE), understanding these common codes can significantly reduce diagnostic time and improve the accuracy of repairs. For instance, P0300 often points to problems with ignition, fuel, or compression, while P0171 typically indicates a vacuum leak or a faulty oxygen sensor.

Here’s a list of common OBD2 codes and their meanings:

| Code | Meaning | Possible Causes |

|---|---|---|

| P0300 | Random/Multiple Cylinder Misfire Detected | Faulty spark plugs, ignition coils, fuel injectors, vacuum leaks |

| P0171 | System Too Lean (Bank 1) | Vacuum leaks, faulty oxygen sensor, fuel pump issues, clogged fuel filter |

| P0420 | Catalyst System Efficiency Below Threshold | Faulty catalytic converter, oxygen sensor issues, exhaust leaks |

| P0101 | Mass Air Flow (MAF) Sensor Range/Performance | Dirty or faulty MAF sensor, vacuum leaks, intake air restrictions |

| P0301 | Cylinder 1 Misfire Detected | Faulty spark plug, ignition coil, fuel injector |

| P0113 | Intake Air Temperature Sensor Circuit High | Faulty IAT sensor, wiring issues |

| P0011 | “A” Camshaft Position – Timing Over-Advanced or System Performance (Bank 1) | Faulty camshaft position sensor, oil control valve, timing chain issues |

| P0401 | Exhaust Gas Recirculation Flow Insufficient Detected | Clogged EGR valve, faulty EGR solenoid, vacuum leaks |

| P0442 | Evaporative Emission Control System Leak Detected (Small Leak) | Loose fuel cap, damaged fuel tank, faulty purge valve |

| P0505 | Idle Air Control System Malfunction | Dirty or faulty IAC valve, vacuum leaks |

2.3. Using Online Databases to Interpret OBD2 Codes

How can online databases assist in interpreting OBD2 codes, and what are some reliable resources available for accurate code definitions and troubleshooting tips? Online databases provide a wealth of information for interpreting OBD2 codes, offering accurate code definitions, troubleshooting tips, and potential solutions, making them invaluable resources for both DIYers and professional mechanics. According to a study by the Automotive Aftermarket Industry Association (AAIA), online databases like OBD-Codes.com, Autozone, and RepairPal are widely used for their comprehensive coverage and user-friendly interfaces. These resources often include detailed descriptions of the codes, possible causes, and step-by-step repair instructions.

Here are some reliable online databases:

- OBD-Codes.com: Offers a comprehensive database of OBD2 codes with detailed descriptions and troubleshooting tips.

- AutoZone: Provides code definitions and potential solutions, along with access to repair manuals and parts.

- RepairPal: Features a database of OBD2 codes and repair estimates, as well as a forum for discussing vehicle issues.

- NHTSA (National Highway Traffic Safety Administration): Offers safety information and technical service bulletins related to OBD2 codes.

- SAE International: Provides access to technical papers and standards related to automotive diagnostics and OBD2 systems.

3. Addressing Common Digital OBD2 Code Reader Errors

What are the most common errors encountered when using digital OBD2 code readers, and how can you effectively address and resolve these issues? Common errors with digital OBD2 code readers include connection problems, software glitches, and inaccurate readings, but these can be effectively addressed through systematic troubleshooting steps and ensuring proper scanner maintenance. According to a survey by the Equipment and Tool Institute (ETI), connection issues are often due to damaged OBD2 ports or faulty cables, while software glitches can be resolved by updating the scanner’s firmware. Inaccurate readings may result from outdated scanner databases or incorrect usage.

3.1. Troubleshooting Connection Errors

How do you troubleshoot connection errors with digital OBD2 code readers to ensure reliable communication with your vehicle’s computer system? Troubleshooting connection errors with digital OBD2 code readers involves checking the OBD2 port for damage, ensuring the cable is securely connected, and verifying the scanner’s compatibility with your vehicle, all of which help establish reliable communication. According to a technical bulletin from Bosch Automotive, connection issues are frequently caused by corrosion or damage to the OBD2 port pins. Additionally, incorrect cable insertion or a faulty cable can prevent the scanner from establishing a proper connection.

OBD2 Port Location

OBD2 Port Location

Here are steps to troubleshoot connection errors:

- Inspect the OBD2 Port: Check for any signs of damage or corrosion.

- Secure the Cable: Ensure the OBD2 cable is firmly plugged into both the scanner and the vehicle’s port.

- Verify Compatibility: Confirm that the scanner is compatible with your vehicle’s make, model, and year.

- Test the Cable: Use a different OBD2 cable to rule out a faulty cable.

- Check Vehicle Power: Ensure the vehicle’s ignition is turned on, but the engine is not running.

- Consult the Manual: Refer to the scanner’s user manual for specific troubleshooting tips.

3.2. Resolving Software and Firmware Issues

How can you resolve software and firmware issues with digital OBD2 code readers to ensure accurate and reliable diagnostic results? Resolving software and firmware issues with digital OBD2 code readers involves regularly updating the scanner’s software, performing a factory reset if necessary, and ensuring the device is compatible with your vehicle’s software protocols, ensuring accurate and reliable diagnostic results. According to a study by Innova Electronics, outdated software can lead to inaccurate code readings and compatibility issues, emphasizing the importance of keeping the scanner updated. A factory reset can often resolve glitches caused by corrupted data or incorrect settings.

Here’s how to resolve software and firmware issues:

- Update the Software: Regularly check for and install software updates from the manufacturer.

- Perform a Factory Reset: Reset the scanner to its default settings to clear any corrupted data.

- Verify Compatibility: Ensure the scanner supports your vehicle’s software protocols (e.g., CAN, J1850).

- Reinstall Software: If problems persist, try reinstalling the software from the manufacturer’s website.

- Check for Driver Issues: Ensure the necessary drivers are installed correctly on your computer if using a PC-based scanner.

- Contact Support: Contact the manufacturer’s support team for assistance with persistent software issues.

3.3. Handling Inaccurate Code Readings

What steps should you take when you encounter inaccurate code readings from your digital OBD2 code reader to ensure you are diagnosing the correct vehicle problems? When encountering inaccurate code readings from a digital OBD2 code reader, it is crucial to verify the code with a second scan, check for software updates, and consult vehicle-specific repair information to ensure an accurate diagnosis. A report by the National Automotive Service Task Force (NASTF) highlights that inaccurate readings can result from outdated software, faulty sensors, or misinterpretation of the data. Always cross-reference the code with multiple sources to confirm its validity.

Here are the steps to handle inaccurate code readings:

- Verify the Code: Perform a second scan to confirm the code is consistently reported.

- Check for Updates: Ensure your OBD2 scanner has the latest software and firmware updates.

- Consult Repair Information: Refer to vehicle-specific repair manuals or online databases for accurate code definitions and troubleshooting tips.

- Check Sensor Data: Review live sensor data to identify any abnormalities that may be triggering the code.

- Inspect Components: Physically inspect the components related to the code for signs of damage or wear.

- Seek Professional Advice: Consult a professional mechanic for a second opinion if you are unsure about the accuracy of the reading.

4. Advanced Techniques for Using Digital OBD2 Scanners

What advanced techniques can enhance the effectiveness of digital OBD2 scanners in diagnosing complex vehicle issues? Advanced techniques for using digital OBD2 scanners include live data analysis, freeze frame data review, and performing advanced diagnostic tests, all of which enhance diagnostic accuracy and efficiency for complex vehicle issues. According to a training manual by Delphi Automotive, live data analysis allows technicians to monitor real-time sensor readings to identify intermittent problems, while freeze frame data provides a snapshot of the vehicle’s condition when a fault code was triggered. Advanced tests, such as O2 sensor testing and EVAP system testing, can further pinpoint the source of the problem.

4.1. Utilizing Live Data Analysis

How can you effectively utilize live data analysis with digital OBD2 scanners to diagnose intermittent or performance-related vehicle issues? Effectively utilizing live data analysis with digital OBD2 scanners involves monitoring real-time sensor readings, identifying deviations from normal parameters, and correlating these deviations with specific symptoms or conditions to diagnose intermittent or performance-related issues. A technical paper from the Society of Automotive Engineers (SAE) emphasizes that live data analysis can reveal subtle issues that may not trigger a diagnostic trouble code (DTC) but still affect vehicle performance. By observing how sensors respond under different operating conditions, technicians can pinpoint the root cause of the problem.

Here are key steps for utilizing live data analysis:

- Select Relevant Parameters: Choose the sensor data that is most relevant to the issue you are investigating (e.g., engine RPM, coolant temperature, oxygen sensor readings).

- Monitor Data Under Various Conditions: Observe the data while the vehicle is idling, accelerating, and cruising to identify any anomalies.

- Compare to Specifications: Compare the live data readings to the manufacturer’s specifications to determine if they fall within the normal range.

- Look for Correlations: Identify any correlations between sensor readings and vehicle symptoms to pinpoint the cause of the problem.

- Use Graphing Tools: Utilize the scanner’s graphing capabilities to visualize the data and identify trends or patterns.

- Record and Review Data: Record the data for later analysis and comparison.

4.2. Interpreting Freeze Frame Data

What is freeze frame data in the context of digital OBD2 scanners, and how can you interpret it to gain insights into the conditions under which a fault code was triggered? Freeze frame data in digital OBD2 scanners is a snapshot of the vehicle’s sensor readings at the moment a fault code was triggered, providing valuable insights into the conditions that led to the malfunction and aiding in accurate diagnosis. According to a report by the Equipment and Tool Institute (ETI), freeze frame data can help technicians understand the operating conditions (e.g., engine load, RPM, coolant temperature) at the time the code was set, which can narrow down the possible causes.

Here’s how to interpret freeze frame data:

- Access Freeze Frame Data: Use your OBD2 scanner to access the freeze frame data associated with the fault code.

- Review Key Parameters: Examine the values of key parameters such as engine RPM, vehicle speed, coolant temperature, and fuel trim.

- Identify Abnormal Conditions: Look for any abnormal conditions or values that may have contributed to the fault.

- Correlate with Symptoms: Correlate the freeze frame data with the vehicle’s symptoms to gain a better understanding of the problem.

- Compare to Normal Values: Compare the freeze frame data to the manufacturer’s specifications or known good values to identify deviations.

- Use in Conjunction with Live Data: Use the freeze frame data in conjunction with live data analysis to further pinpoint the cause of the problem.

4.3. Performing Advanced Diagnostic Tests

What advanced diagnostic tests can be performed using digital OBD2 scanners to further pinpoint vehicle issues beyond basic code reading? Advanced diagnostic tests that can be performed using digital OBD2 scanners include O2 sensor testing, EVAP system testing, and ABS/SRS diagnostics, which help pinpoint vehicle issues beyond basic code reading. According to a training manual by Snap-on, these tests can provide detailed insights into the performance of specific components and systems. O2 sensor testing assesses the functionality of oxygen sensors, EVAP system testing checks for leaks in the evaporative emissions control system, and ABS/SRS diagnostics troubleshoot issues with the anti-lock braking system and supplemental restraint system.

Here are some advanced diagnostic tests:

- O2 Sensor Testing: Evaluates the performance of oxygen sensors by monitoring their voltage output and response time.

- EVAP System Testing: Checks for leaks in the evaporative emissions control system using pressure or vacuum tests.

- ABS/SRS Diagnostics: Troubleshoots issues with the anti-lock braking system and supplemental restraint system by reading and clearing ABS/SRS codes and monitoring sensor data.

- Fuel Injector Testing: Assesses the performance of fuel injectors by measuring their resistance and pulse width.

- EGR Valve Testing: Evaluates the functionality of the exhaust gas recirculation (EGR) valve by monitoring its position and flow rate.

5. Maintaining Your Digital OBD2 Code Reader

How do you properly maintain your digital OBD2 code reader to ensure it remains accurate, reliable, and in optimal working condition for years to come? Proper maintenance of a digital OBD2 code reader involves keeping the software updated, storing the device in a safe environment, and regularly inspecting the cable and connectors to ensure accuracy and reliability. According to a guide by the Equipment and Tool Institute (ETI), regular software updates ensure that the scanner has the latest code definitions and diagnostic capabilities. Storing the scanner in a clean, dry place protects it from damage, and inspecting the cable and connectors prevents connection issues.

5.1. Keeping Software and Firmware Updated

Why is it essential to keep the software and firmware of your digital OBD2 code reader updated, and how do you ensure you have the latest versions installed? Keeping the software and firmware of your digital OBD2 code reader updated is essential for ensuring accurate code readings, compatibility with newer vehicles, and access to the latest diagnostic features, all of which improve the scanner’s performance and reliability. A study by Innova Electronics highlights that outdated software can lead to inaccurate code interpretations and compatibility issues with newer vehicle models. Regularly updating the software ensures that the scanner has the latest code definitions and diagnostic algorithms.

Here’s how to keep your scanner updated:

- Check for Updates Regularly: Visit the manufacturer’s website or use the scanner’s built-in update feature to check for new software and firmware updates.

- Follow the Update Instructions: Carefully follow the manufacturer’s instructions for installing the updates.

- Backup Your Data: Before performing an update, back up any important data or settings on the scanner.

- Ensure Stable Power: Make sure the scanner has a stable power source during the update process to prevent interruptions.

- Verify Installation: After the update is complete, verify that the new software and firmware versions are installed correctly.

- Subscribe to Notifications: Subscribe to the manufacturer’s email list or other notification services to receive alerts about new updates.

5.2. Proper Storage and Handling

What are the best practices for the proper storage and handling of your digital OBD2 code reader to prevent damage and prolong its lifespan? Best practices for proper storage and handling of a digital OBD2 code reader include storing it in a protective case, keeping it away from extreme temperatures and moisture, and avoiding dropping or mishandling the device to prevent damage and prolong its lifespan. According to a guide by Snap-on, storing the scanner in a case protects it from physical damage, while avoiding extreme temperatures and moisture prevents electronic components from deteriorating.

Here are some storage and handling tips:

- Use a Protective Case: Store the scanner in a protective case to shield it from dust, dirt, and physical damage.

- Avoid Extreme Temperatures: Keep the scanner away from extreme heat and cold, as these can damage the electronic components.

- Protect from Moisture: Store the scanner in a dry environment to prevent corrosion and electrical issues.

- Handle with Care: Avoid dropping or mishandling the scanner, as this can damage the internal components.

- Clean Regularly: Clean the scanner with a soft, dry cloth to remove dust and dirt.

- Store Cables Properly: Coil the OBD2 cable neatly and store it in a way that prevents kinks or damage.

5.3. Inspecting Cables and Connectors

How often should you inspect the cables and connectors of your digital OBD2 code reader, and what signs of wear or damage should you look for? You should inspect the cables and connectors of your digital OBD2 code reader regularly, ideally before each use, looking for signs of wear, damage, or corrosion to ensure a reliable connection and accurate readings. According to a technical bulletin from Bosch Automotive, damaged cables or corroded connectors can cause intermittent connection issues or prevent the scanner from communicating with the vehicle’s computer.

Here are some signs of wear or damage to look for:

- Frays or Cuts: Check the cable for any frays, cuts, or exposed wires.

- Bent or Broken Pins: Inspect the OBD2 connector for bent or broken pins.

- Corrosion: Look for signs of corrosion on the connector pins or cable ends.

- Loose Connections: Ensure the connectors fit snugly into the OBD2 port and the scanner.

- Cracked Housings: Check the connector housings for any cracks or damage.

- Stiff or Brittle Cables: If the cable feels stiff or brittle, it may be damaged and need replacement.

6. Choosing the Right Digital OBD2 Scanner

What factors should you consider when choosing the right digital OBD2 scanner for your needs, ensuring you get the best value and functionality for your investment? When choosing a digital OBD2 scanner, consider compatibility with your vehicle, features needed (e.g., live data, ABS/SRS diagnostics), ease of use, and budget to ensure you get the best value and functionality. According to a review by Consumer Reports, the ideal scanner should offer comprehensive vehicle coverage, accurate readings, and a user-friendly interface. Additional factors to consider include the scanner’s ability to perform advanced tests, its connectivity options (e.g., Wi-Fi, Bluetooth), and the availability of software updates.

6.1. Compatibility with Vehicle Make and Model

Why is compatibility with your vehicle’s make and model a crucial factor when selecting a digital OBD2 scanner? Compatibility with your vehicle’s make and model is crucial when selecting a digital OBD2 scanner because it ensures that the scanner can properly communicate with your vehicle’s computer and accurately read diagnostic trouble codes (DTCs). According to a report by the Society of Automotive Engineers (SAE), not all OBD2 scanners are compatible with all vehicles, and using an incompatible scanner can result in inaccurate readings or a failure to connect.

Here’s how to ensure compatibility:

- Check the Scanner Specifications: Review the scanner’s specifications to confirm that it supports your vehicle’s make, model, and year.

- Consult the Manufacturer’s Website: Visit the scanner manufacturer’s website to check for a compatibility list or vehicle coverage tool.

- Read User Reviews: Look for user reviews or testimonials from other vehicle owners to see if the scanner has been tested with your specific vehicle.

- Ask the Seller: If purchasing from a retailer, ask the seller to verify compatibility before making a purchase.

- Look for Generic and Enhanced Codes: Ensure the scanner supports both generic OBD2 codes and manufacturer-specific enhanced codes for your vehicle.

- Consider Future Vehicles: If you plan to use the scanner on multiple vehicles in the future, choose a model with broad compatibility.

6.2. Essential Features vs. Advanced Capabilities

What are the essential features every digital OBD2 scanner should have, and what advanced capabilities might be worth considering based on your diagnostic needs? Essential features for every digital OBD2 scanner include the ability to read and clear diagnostic trouble codes (DTCs), view live data, and perform basic system tests, while advanced capabilities like ABS/SRS diagnostics, O2 sensor testing, and bidirectional control may be worth considering based on your diagnostic needs. According to a survey by the Automotive Aftermarket Industry Association (AAIA), the most commonly used features are DTC reading and clearing, followed by live data analysis. However, advanced capabilities can provide more in-depth diagnostic information for complex issues.

Here’s a breakdown of essential vs. advanced features:

Essential Features:

- DTC Reading and Clearing: The ability to read and clear diagnostic trouble codes.

- Live Data Streaming: Real-time data from vehicle sensors.

- Basic System Tests: Tests for basic vehicle systems like the engine and transmission.

- Vehicle Information: Access to vehicle identification number (VIN) and calibration information.

- User-Friendly Interface: An intuitive and easy-to-navigate display.

Advanced Capabilities:

- ABS/SRS Diagnostics: Diagnostics for the anti-lock braking system and supplemental restraint system.

- O2 Sensor Testing: Tests for oxygen sensor performance.

- EVAP System Testing: Tests for leaks in the evaporative emissions control system.

- Bidirectional Control: The ability to send commands to vehicle components for testing purposes.

- Graphing Capabilities: Graphing of live data for easier analysis.

- Wi-Fi/Bluetooth Connectivity: Wireless connectivity for updates and data transfer.

6.3. Budget Considerations and Long-Term Value

How should you balance budget considerations with the long-term value and functionality when selecting a digital OBD2 scanner, ensuring you make a wise investment? When selecting a digital OBD2 scanner, balance budget considerations with long-term value by assessing your diagnostic needs, comparing features across different price points, and considering the potential cost savings from DIY repairs. According to a study by Consumer Reports, while cheaper scanners may offer basic functionality, investing in a higher-quality scanner with advanced features and reliable software updates can save money in the long run by enabling more accurate diagnoses and preventing costly repairs.

Here are some tips for balancing budget and value:

- Assess Your Needs: Determine what features are essential for your diagnostic needs and what features are nice to have but not critical.

- Compare Scanners: Compare scanners across different price points, looking at their features, compatibility, and user reviews.

- Consider Long-Term Costs: Factor in the potential cost savings from DIY repairs that the scanner will enable, as well as the cost of software updates and potential repairs to the scanner itself.

- Read Reviews: Look for reviews from other users to get an idea of the scanner’s reliability and performance.

- Check Warranty: Check the warranty offered by the manufacturer to protect against defects or malfunctions.

- Look for Value Bundles: Consider purchasing a scanner as part of a value bundle that includes additional accessories or software.

7. Case Studies: Real-World OBD2 Code Reader Error Solutions

Can you provide some real-world case studies where digital OBD2 code readers were used to successfully diagnose and resolve vehicle issues, showcasing their practical applications? Real-world case studies demonstrate the practical applications of digital OBD2 code readers in diagnosing and resolving vehicle issues, such as identifying a faulty oxygen sensor causing poor fuel economy or diagnosing a misfire due to a faulty ignition coil. According to case studies from the National Institute for Automotive Service Excellence (ASE), OBD2 scanners can significantly reduce diagnostic time and improve the accuracy of repairs.

7.1. Diagnosing a Misfire Issue

How can a digital OBD2 code reader be used to diagnose a misfire issue in a vehicle, and what steps should be taken to identify and resolve the root cause? A digital OBD2 code reader can effectively diagnose a misfire issue by identifying specific cylinder misfire codes (e.g., P0301, P0302) and providing live data to assess engine performance, enabling technicians to pinpoint and resolve the root cause. According to a case study by Delphi Automotive, misfires can be caused by a variety of factors, including faulty spark plugs, ignition coils, fuel injectors, or vacuum leaks. The OBD2 scanner helps narrow down the possibilities by providing specific codes and real-time data.

Here are the steps to diagnose a misfire issue:

- Read the Codes: Use the OBD2 scanner to read and record any misfire codes (e.g., P0300, P0301, P0302).

- Check Live Data: Monitor live data parameters such as engine RPM, coolant temperature, and fuel trim to identify any abnormalities.

- Inspect Spark Plugs: Check the spark plugs for signs of wear, damage, or fouling.

- Test Ignition Coils: Test the ignition coils using a multimeter or spark tester to ensure they are functioning properly.

- Check Fuel Injectors: Inspect the fuel injectors for clogs or leaks, and test their resistance and pulse width.

- Look for Vacuum Leaks: Check for vacuum leaks using a smoke machine or carburetor cleaner.

- Perform Compression Test: Perform a compression test to rule out any issues with the engine’s cylinders.

7.2. Identifying Oxygen Sensor Problems

How can a digital OBD2 code reader assist in identifying oxygen sensor problems affecting fuel efficiency and emissions? A digital OBD2 code reader assists in identifying oxygen sensor problems by displaying specific codes related to O2 sensor performance (e.g., P0131, P0137) and providing live data to monitor sensor voltage and response time, which directly affect fuel efficiency and emissions. According to a case study by Bosch Automotive, faulty oxygen sensors can cause a vehicle to run rich or lean, leading to poor fuel economy and increased emissions. The OBD2 scanner helps diagnose these issues by providing real-time data and fault codes.

Here are the steps to identify oxygen sensor problems:

- Read the Codes: Use the OBD2 scanner to read and record any oxygen sensor codes (e.g., P0131, P0137).

- Check Live Data: Monitor live data parameters such as O2 sensor voltage, fuel trim, and air-fuel ratio to identify any abnormalities.

- Test Sensor Response: Use the scanner to perform an O2 sensor test, which measures the sensor’s response time and voltage output.

- Inspect Sensor Wiring: Check the oxygen sensor wiring for any damage or corrosion.

- Look for Exhaust Leaks: Check for exhaust leaks near the oxygen sensor, as these can affect its readings.

- Replace Faulty Sensor: Replace the faulty oxygen sensor with a new one, and clear the codes using the OBD2 scanner.

7.3. Resolving ABS and SRS Issues

How can a digital OBD2 code reader be utilized to diagnose and resolve issues related to the anti-lock braking system (ABS) and supplemental restraint system (SRS) in a vehicle? A digital OBD2 code reader can diagnose and resolve ABS and SRS issues by reading specific ABS and SRS codes, accessing live data from wheel speed sensors and airbag modules, and allowing for system resets after repairs, ensuring proper functionality. According to a case study by Snap-on, ABS and SRS issues can range from faulty wheel speed sensors to airbag module malfunctions. The OBD2 scanner helps pinpoint the problem by providing specific codes and data.

Here are the steps to resolve ABS and SRS issues:

- Read the Codes: Use the OBD2 scanner to read and record any ABS or SRS codes.

- Check Live Data: Monitor live data parameters such as wheel speed sensor readings and airbag module status to identify any abnormalities.

- Inspect Wheel Speed Sensors: Check the wheel speed sensors for damage, and test their resistance and output voltage.

- Check Airbag Module Connections: Inspect the airbag module connections for corrosion or loose wires.

- Perform System Reset: After making repairs, use the OBD2 scanner to perform a system reset and clear the codes.

- Test the System: Test the ABS and SRS systems to ensure they are functioning properly.

8. The Future of Digital OBD2 Technology

What emerging trends and advancements can we expect to see in digital OBD2 technology in the coming years, and how will these innovations impact vehicle diagnostics? Emerging trends in digital OBD2 technology include enhanced wireless connectivity, cloud-based diagnostics, and integration with artificial intelligence (AI), which will significantly impact vehicle diagnostics by enabling more accurate, efficient, and proactive maintenance. According to a report by McKinsey & Company, the automotive industry is rapidly adopting connected car technologies, and OBD2 scanners are evolving to leverage these advancements.

8.1. Wireless Connectivity and Cloud-Based Diagnostics

How will wireless connectivity and cloud-based diagnostics transform the capabilities of digital OBD2 scanners in the future? Wireless connectivity and cloud-based diagnostics will transform digital OBD2 scanners by enabling real-time data sharing, remote diagnostics, and access to comprehensive vehicle databases, leading to faster and more accurate diagnoses. According to a study by the Automotive Aftermarket Suppliers Association (AASA), cloud-based diagnostics can provide technicians with access to a vast amount of data, including repair histories, diagnostic tips, and software updates, all of which enhance their ability to troubleshoot complex issues.

Here are some ways wireless connectivity and cloud-based diagnostics will transform OBD2 scanners:

- Real-Time Data Sharing: Allows technicians to share diagnostic data with remote experts or access cloud-based databases for assistance.

- Remote Diagnostics: Enables remote technicians to diagnose and troubleshoot vehicle issues from anywhere in the world.

- Over-the-Air Updates: Provides automatic software and firmware updates via a wireless connection.

- Access to Comprehensive Databases: Gives technicians access to a vast amount of vehicle-specific information, including repair histories, diagnostic tips, and technical service bulletins.

- Predictive Maintenance: Uses data analytics to predict potential vehicle issues and schedule maintenance proactively.

8.2. Integration with Artificial Intelligence (AI)

How will the integration of artificial intelligence (AI)