Contents

- 1. Can Your OBD2 Scanner Read Fuel Pump Pressure?

- 2. Understanding the Capabilities and Limitations of OBD2 Scanners

- 2.1. Capabilities of OBD2 Scanners

- 2.2. Why Are These Devices Limited in Their Capabilities?

- 3. Alternative Methods to Monitor Fuel Pump Pressure

- 4. How OBD2 Scanners Work: A Deep Dive

- 4.1. Understanding OBD2 Protocols

- 4.2. The Role of the ECU in Fuel Pressure Monitoring

- 5. The Fuel System and Its Components

- 5.1. The Fuel Pump: Heart of the System

- 5.2. The Fuel Pressure Regulator: Maintaining Consistency

- 5.3. The Fuel Injectors: Precise Delivery

- 6. Diagnosing Fuel Pressure Issues with OBD2 Scanners

- 6.1. Interpreting Diagnostic Trouble Codes (DTCs)

- 6.2. Using Live Data for Diagnosis

- 7. Advanced Diagnostic Tools for Fuel Pressure Monitoring

- 7.1. Examples of Advanced OBD2 Scanners

- 7.2. Using Manual Fuel Pressure Gauges

- 8. Maintaining Optimal Fuel Pressure: Best Practices

- 9. Case Studies: Real-World Examples

- 9.1. Case Study 1: Diagnosing a Lean Condition

- 9.2. Case Study 2: Diagnosing a Rough Idle

- 10. The Future of OBD2 Technology and Fuel Pressure Monitoring

- 10.1. The Role of Telematics

- 10.2. The Impact of Electric Vehicles (EVs)

- Conclusion

- FAQ

- Can you read fuel pressure with a scanner?

- Will a fuel pump show up on a code reader?

- How to test your fuel pump pressure?

1. Can Your OBD2 Scanner Read Fuel Pump Pressure?

Knowing the capabilities and limitations of your diagnostic tools is crucial for effective car maintenance. Most basic OBD2 scanners aren’t designed to read fuel pump pressure directly. These scanners excel at reading error codes and identifying issues that trigger the check engine light, but they often lack the specialized capabilities needed to monitor specific parameters like fuel pump pressure.

Fuel pump pressure indicates how efficiently your car’s fuel delivery system functions. Insufficient pressure can lead to your engine not receiving enough fuel, resulting in poor performance or stalling. Conversely, excessive pressure can cause rough idling or misfires.

Monitoring fuel pump pressure helps prevent more significant and costly engine problems later on.

Complete Systems Diagnostic Car Scanner | Foxwell

Complete Systems Diagnostic Car Scanner | Foxwell

Alt: NT710 Full Systems Diagnostic Scanner displaying comprehensive vehicle health information, aiding in automotive diagnostics.

2. Understanding the Capabilities and Limitations of OBD2 Scanners

OBD2 scanners are invaluable for keeping your car running smoothly. These devices read and clear trouble codes, monitor engine parameters, and perform emissions tests, offering a mini diagnostic lab in your glovebox. However, while OBD2 scanners have immense potential, they also have limitations, particularly in displaying specific data like fuel pump pressure readings.

2.1. Capabilities of OBD2 Scanners

Most OBD2 scanners are built to perform specific tasks effectively:

- Read and Clear Diagnostic Trouble Codes (DTCs): DTCs help identify issues that trigger the check engine light, such as malfunctioning oxygen sensors or misfiring engines. Using an OBD2 scanner to assess these codes is essential for diagnosing vehicle problems.

- Monitor Real-time Information: Scanners provide real-time data such as engine RPM, coolant temperature, and fuel system status, offering insight into your vehicle’s performance at any moment. This data is essential for understanding overall performance.

- Emissions Testing: OBD2 scanners can also assist in checking whether your car meets emissions standards required by state inspections in various locations, making them essential for passing these inspections.

OBD2 scanners have proven their worth as essential tools in routine vehicle maintenance and troubleshooting common issues. However, their capabilities may be limited when dealing with more specific parameters like fuel pump pressure.

2.2. Why Are These Devices Limited in Their Capabilities?

Why don’t these gadgets suffice in terms of reading fuel pump pressure accurately? It comes down to how vehicles communicate data. Standard OBD2 scanners are designed to interact with a car’s onboard diagnostic system, which focuses on emissions-related components and systems affecting its check engine light.

Not all vehicle sensors must communicate through this OBD2 system; fuel pump pressure is one such parameter that often escapes its purview. Consider OBD2 like a public broadcast channel: it provides essential, broad-reaching information for most cars. However, additional tools or channels may be necessary to capture such signals for specific, detailed data like fuel pump pressure measurements.

According to a study by the Society of Automotive Engineers (SAE), standard OBD2 protocols primarily focus on emissions-related data, with limited support for other vehicle-specific parameters. This limitation explains why OBD2 scanners designed for general diagnostics typically lack the capability to monitor fuel pump pressure.

To access more specific details, advanced diagnostic tools or gauges explicitly designed for that task may be necessary.

3. Alternative Methods to Monitor Fuel Pump Pressure

If your OBD2 scanner can’t read fuel pump pressure, there are effective and reliable ways to gain this vital information.

One direct method is using a manual fuel pressure gauge, which connects directly to your vehicle’s fuel rail or line, allowing you to manually measure pressure directly. This is similar to checking tire pressure with a gauge; it’s simple yet reliable and effective!

Referring to your vehicle service manual for attachment points will help you get an accurate reading as soon as it’s attached.

Alternatively, consider investing in an advanced OBD2 scanner or diagnostic tool capable of reading fuel pump pressure. Tools like the Foxwell NT650 Elite or Foxwell GT60 offer access to more vehicle data, including fuel pressure.

Although more costly than basic models, such scanners provide much deeper insight into your car’s performance by accessing live ECU information directly, making them invaluable investments for anyone serious about maintaining their vehicle.

Complete diagnostic kits with fuel pressure gauges and other essential tools may be ideal for accurately monitoring your engine’s fuel pump pressure and maintaining optimal engine performance. These kits typically include various adapters to fit multiple vehicle models and detailed instructions, allowing even novice mechanics to use them effectively.

According to research from the National Institute for Automotive Service Excellence (ASE), using specialized tools like fuel pressure gauges ensures accurate readings, leading to more precise diagnoses and effective repairs.

This approach allows for accurate vehicle fuel pump pressure monitoring to ensure engine health at its highest performance levels.

Car Scanner Functions | Foxwell

Car Scanner Functions | Foxwell

Alt: NT530 Advanced Maintenance Service Scanner showcasing diverse vehicle diagnostic functions, enabling comprehensive automotive care.

4. How OBD2 Scanners Work: A Deep Dive

To fully understand the role of OBD2 scanners in determining fuel pressure, it’s essential to delve into how these devices function. OBD2 scanners work by communicating with your vehicle’s Engine Control Unit (ECU), the central computer that manages various engine functions.

Here’s a breakdown of the process:

- Connection: The OBD2 scanner plugs into the OBD2 port, typically located under the dashboard.

- Communication: The scanner sends a request for data to the ECU.

- Data Retrieval: The ECU responds by sending back data related to various sensors and systems within the vehicle.

- Interpretation: The scanner interprets this data and displays it in a user-friendly format, such as error codes, live sensor readings, and diagnostic reports.

The data transmitted through the OBD2 system includes information about emissions-related components, engine performance, and other vital parameters. However, as mentioned earlier, not all parameters are accessible through the standard OBD2 protocol.

4.1. Understanding OBD2 Protocols

OBD2 (On-Board Diagnostics II) is a standardized system mandated in the United States for all cars manufactured after 1996. Its primary purpose is to monitor emissions-related components and systems, ensuring vehicles meet environmental regulations.

The OBD2 system uses various communication protocols to transmit data between the ECU and the diagnostic tool. Some common protocols include:

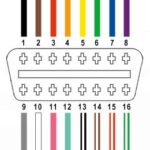

- SAE J1850 VPW: Used primarily by General Motors vehicles.

- SAE J1850 PWM: Used primarily by Ford vehicles.

- ISO 9141-2: Used by European and Asian vehicles.

- ISO 14230 (KWP2000): Used by European and Asian vehicles.

- CAN (Controller Area Network): The most modern protocol, used by most vehicles manufactured after 2008.

Each protocol has its own set of rules and standards for transmitting data. The OBD2 scanner must be compatible with the protocol used by your vehicle to communicate effectively.

4.2. The Role of the ECU in Fuel Pressure Monitoring

The ECU plays a crucial role in monitoring and controlling fuel pressure. It receives input from various sensors, including the fuel pressure sensor, and adjusts the fuel pump’s operation to maintain the desired pressure level.

The fuel pressure sensor provides real-time feedback to the ECU, allowing it to make precise adjustments to the fuel pump’s speed and output. If the fuel pressure deviates from the specified range, the ECU can take corrective action, such as increasing or decreasing the fuel pump’s voltage.

In some vehicles, the ECU may also store diagnostic trouble codes related to fuel pressure issues. These codes can be retrieved using an OBD2 scanner, providing valuable information for diagnosing fuel system problems.

5. The Fuel System and Its Components

To fully appreciate how OBD2 scanners interact with fuel pressure, it’s essential to understand the fuel system and its key components. The fuel system is responsible for delivering fuel from the fuel tank to the engine, ensuring a consistent and adequate supply for combustion.

Here are the main components of a typical fuel system:

- Fuel Tank: Stores the fuel supply.

- Fuel Pump: Pumps fuel from the tank to the engine.

- Fuel Filter: Removes contaminants from the fuel.

- Fuel Pressure Regulator: Maintains a constant fuel pressure in the fuel rail.

- Fuel Injectors: Spray fuel into the engine’s cylinders.

- Fuel Rail: Distributes fuel to the injectors.

- Fuel Pressure Sensor: Monitors fuel pressure in the fuel rail.

5.1. The Fuel Pump: Heart of the System

The fuel pump is the heart of the fuel system, responsible for pumping fuel from the tank to the engine. It’s typically located inside the fuel tank or along the fuel line.

Fuel pumps come in various designs, including:

- Mechanical Fuel Pumps: Driven by the engine’s camshaft, used in older vehicles.

- Electric Fuel Pumps: Powered by an electric motor, used in most modern vehicles.

Electric fuel pumps are more efficient and reliable than mechanical pumps, and they can deliver fuel at a higher pressure. They’re also easier to control electronically, allowing the ECU to adjust the fuel pump’s output based on engine demand.

5.2. The Fuel Pressure Regulator: Maintaining Consistency

The fuel pressure regulator is responsible for maintaining a constant fuel pressure in the fuel rail. It’s typically located on the fuel rail or near the fuel injectors.

The fuel pressure regulator works by bleeding off excess fuel pressure back to the fuel tank. This ensures that the fuel injectors receive a consistent supply of fuel, regardless of engine speed or load.

If the fuel pressure regulator malfunctions, it can cause fuel pressure to be too high or too low, leading to various engine problems.

5.3. The Fuel Injectors: Precise Delivery

The fuel injectors are responsible for spraying fuel into the engine’s cylinders. They’re typically located in the intake manifold or directly in the cylinder head.

Fuel injectors are precisely controlled by the ECU, which determines the amount of fuel to inject based on engine demand. The ECU also controls the timing of the fuel injection, ensuring that the fuel is injected at the optimal moment for combustion.

Fuel injectors are critical components of the fuel system, and their proper operation is essential for efficient engine performance.

6. Diagnosing Fuel Pressure Issues with OBD2 Scanners

While basic OBD2 scanners may not read fuel pressure directly, they can still provide valuable information for diagnosing fuel pressure issues. By monitoring other parameters related to the fuel system, you can often narrow down the possible causes of fuel pressure problems.

Here are some parameters that can be helpful:

- Fuel Trim: Indicates whether the engine is running lean (too much air) or rich (too much fuel).

- Oxygen Sensor Readings: Provide information about the air-fuel mixture in the exhaust.

- Mass Airflow (MAF) Sensor Readings: Measure the amount of air entering the engine.

- Engine RPM: Indicates the speed of the engine.

- Engine Load: Indicates how much power the engine is producing.

By analyzing these parameters, you can often determine whether the fuel system is functioning correctly. For example, if the fuel trim is consistently positive (indicating a lean condition), it could be a sign of low fuel pressure.

6.1. Interpreting Diagnostic Trouble Codes (DTCs)

OBD2 scanners can also retrieve diagnostic trouble codes (DTCs) related to the fuel system. These codes can provide valuable clues about the nature of the problem.

Here are some common DTCs related to fuel pressure:

| DTC Code | Description | Possible Causes |

|---|---|---|

| P0087 | Fuel Rail/System Pressure Too Low | Faulty fuel pump, clogged fuel filter, faulty fuel pressure regulator, fuel leak |

| P0088 | Fuel Rail/System Pressure Too High | Faulty fuel pressure regulator, restricted fuel return line |

| P0089 | Fuel Pressure Regulator Performance | Faulty fuel pressure regulator, wiring issue |

| P0090 | Fuel Pressure Regulator Control Circuit | Faulty fuel pressure regulator, wiring issue |

| P0171 | System Too Lean (Bank 1) | Low fuel pressure, vacuum leak, faulty MAF sensor, faulty oxygen sensor |

| P0172 | System Too Rich (Bank 1) | High fuel pressure, faulty fuel injectors, faulty oxygen sensor |

| P0174 | System Too Lean (Bank 2) | Low fuel pressure, vacuum leak, faulty MAF sensor, faulty oxygen sensor |

| P0175 | System Too Rich (Bank 2) | High fuel pressure, faulty fuel injectors, faulty oxygen sensor |

By researching the specific DTCs retrieved by your OBD2 scanner, you can gain a better understanding of the potential causes of the fuel pressure problem.

6.2. Using Live Data for Diagnosis

Advanced OBD2 scanners can also display live data from various sensors in the fuel system. This can be extremely helpful for diagnosing fuel pressure issues.

By monitoring the fuel pressure sensor reading in real-time, you can see how the fuel pressure changes under different driving conditions. This can help you identify problems with the fuel pump, fuel pressure regulator, or fuel injectors.

For example, if the fuel pressure drops significantly when the engine is under heavy load, it could be a sign of a weak fuel pump.

7. Advanced Diagnostic Tools for Fuel Pressure Monitoring

While basic OBD2 scanners have limitations, advanced diagnostic tools offer more comprehensive capabilities for monitoring fuel pressure. These tools often include features such as:

- Fuel Pressure Readings: Display real-time fuel pressure data from the fuel pressure sensor.

- Fuel Pump Control: Allow you to control the fuel pump directly for testing purposes.

- Fuel Injector Testing: Allow you to test the operation of individual fuel injectors.

- Graphing Capabilities: Display fuel pressure data in a graphical format for easier analysis.

- Data Logging: Allow you to record fuel pressure data for later analysis.

These advanced features can significantly simplify the process of diagnosing fuel pressure issues.

7.1. Examples of Advanced OBD2 Scanners

Some popular advanced OBD2 scanners that offer fuel pressure monitoring capabilities include:

- Foxwell NT650 Elite: A versatile scanner with a wide range of diagnostic functions, including fuel pressure monitoring.

- Foxwell GT60: A powerful scanner with advanced features such as bi-directional control and coding capabilities.

- Snap-on Solus Edge: A professional-grade scanner with comprehensive diagnostic capabilities.

- Autel MaxiSys MS906BT: A high-end scanner with advanced features such as ECU programming and coding.

These scanners are more expensive than basic OBD2 scanners, but they offer a much wider range of capabilities.

7.2. Using Manual Fuel Pressure Gauges

In addition to advanced OBD2 scanners, manual fuel pressure gauges are another option for monitoring fuel pressure. These gauges connect directly to the fuel rail and provide a direct reading of the fuel pressure.

Manual fuel pressure gauges are relatively inexpensive and easy to use. They don’t require any special tools or software, and they can provide accurate fuel pressure readings.

However, manual fuel pressure gauges do have some limitations. They can be messy to use, as fuel can spill when connecting and disconnecting the gauge. They also require you to access the fuel rail, which can be difficult on some vehicles.

8. Maintaining Optimal Fuel Pressure: Best Practices

Maintaining optimal fuel pressure is essential for ensuring efficient engine performance and preventing fuel system problems. Here are some best practices for maintaining optimal fuel pressure:

- Regular Fuel Filter Replacement: A clogged fuel filter can restrict fuel flow and reduce fuel pressure. Replace the fuel filter according to the manufacturer’s recommendations.

- Fuel System Cleaning: Over time, deposits can build up in the fuel system, restricting fuel flow and reducing fuel pressure. Consider using a fuel system cleaner periodically to remove these deposits.

- Fuel Pump Inspection: If you suspect a fuel pump problem, have it inspected by a qualified mechanic. A weak fuel pump can cause low fuel pressure and various engine problems.

- Fuel Pressure Regulator Inspection: A faulty fuel pressure regulator can cause fuel pressure to be too high or too low. Have it inspected by a qualified mechanic if you suspect a problem.

- Use Quality Fuel: Using high-quality fuel can help prevent deposits from building up in the fuel system.

By following these best practices, you can help ensure that your fuel system operates at peak performance and that your engine receives the fuel it needs.

9. Case Studies: Real-World Examples

To illustrate how OBD2 scanners can be used to diagnose fuel pressure issues, here are a couple of case studies:

9.1. Case Study 1: Diagnosing a Lean Condition

A customer complained of poor fuel economy and a lack of power in their 2010 Honda Civic. The check engine light was on, and the OBD2 scanner retrieved a P0171 code (System Too Lean, Bank 1).

The mechanic used the OBD2 scanner to monitor live data, including fuel trim, oxygen sensor readings, and MAF sensor readings. The fuel trim was consistently positive, indicating a lean condition. The oxygen sensor readings were also fluctuating rapidly, suggesting that the engine was trying to compensate for the lean condition.

The mechanic suspected a fuel pressure problem and used a manual fuel pressure gauge to check the fuel pressure at the fuel rail. The fuel pressure was significantly lower than the specified range.

The mechanic diagnosed a faulty fuel pump and replaced it. After replacing the fuel pump, the fuel pressure returned to normal, and the engine ran smoothly. The P0171 code was cleared, and the customer reported improved fuel economy and performance.

9.2. Case Study 2: Diagnosing a Rough Idle

A customer complained of a rough idle and occasional stalling in their 2005 Ford F-150. The check engine light was not on, and the OBD2 scanner did not retrieve any diagnostic trouble codes.

The mechanic used the OBD2 scanner to monitor live data, including engine RPM, engine load, and fuel pressure (using an advanced scanner). The engine RPM was fluctuating erratically at idle, and the engine load was also unstable. The fuel pressure was slightly higher than the specified range.

The mechanic suspected a faulty fuel pressure regulator and used a manual fuel pressure gauge to confirm the fuel pressure reading. The fuel pressure was indeed higher than the specified range.

The mechanic replaced the fuel pressure regulator. After replacing the fuel pressure regulator, the fuel pressure returned to normal, and the engine idled smoothly. The stalling problem was also resolved.

These case studies demonstrate how OBD2 scanners can be valuable tools for diagnosing fuel pressure issues, even when they don’t read fuel pressure directly.

10. The Future of OBD2 Technology and Fuel Pressure Monitoring

The future of OBD2 technology is bright, with ongoing advancements promising even more comprehensive diagnostic capabilities. As vehicles become increasingly complex, the role of OBD2 scanners will become even more critical.

Some of the key trends in OBD2 technology include:

- Enhanced Data Access: Future OBD2 scanners will likely have access to a wider range of vehicle parameters, including more detailed fuel system data.

- Wireless Connectivity: Wireless OBD2 scanners will become more common, allowing for easier data transfer and remote diagnostics.

- Cloud-Based Diagnostics: Cloud-based diagnostic platforms will provide access to vast databases of diagnostic information, making it easier to diagnose complex problems.

- Artificial Intelligence (AI): AI-powered diagnostic tools will be able to analyze vehicle data and provide more accurate diagnoses.

These advancements will make it easier for mechanics and vehicle owners to diagnose and repair fuel pressure issues and other vehicle problems.

10.1. The Role of Telematics

Telematics systems, which combine telecommunications and informatics, are also playing an increasingly important role in vehicle diagnostics. These systems can collect and transmit vehicle data in real-time, allowing for remote monitoring and diagnostics.

Telematics systems can provide valuable information about fuel pressure, including:

- Fuel Pressure Readings: Real-time fuel pressure data from the fuel pressure sensor.

- Fuel Consumption: Data on fuel consumption rates, which can be used to identify fuel system problems.

- Driving Patterns: Data on driving patterns, which can be used to identify potential fuel system issues.

This data can be used to identify potential fuel pressure issues before they cause major problems, allowing for proactive maintenance and repairs.

10.2. The Impact of Electric Vehicles (EVs)

As electric vehicles (EVs) become more popular, the role of OBD2 scanners will evolve. While EVs don’t have traditional fuel systems, they do have high-voltage battery systems that require monitoring and diagnostics.

OBD2 scanners will be used to monitor the health of the EV battery pack, including:

- Battery Voltage: The overall voltage of the battery pack.

- Cell Voltage: The voltage of individual battery cells.

- Battery Temperature: The temperature of the battery pack.

- State of Charge (SOC): The percentage of battery capacity remaining.

- State of Health (SOH): The overall health and performance of the battery pack.

These parameters will be critical for ensuring the safe and efficient operation of EVs.

Conclusion

Can an OBD2 scanner read fuel pump pressure? It depends on your chosen scanner and vehicle compatibility. While basic OBD2 scanners may not offer this capability, more advanced scanners and methods may offer insights. Monitoring fuel pump pressure is crucial to maintaining vehicle performance and avoiding potential issues. From manual gauges and scanners like Foxwell to comprehensive diagnostic kits, having the appropriate tools for this job is critical to saving time and money. Being proactive with car care can save both time and money.

At OBD2-SCANNER.EDU.VN, we understand the challenges of diagnosing and repairing modern vehicles. That’s why we offer a wide range of OBD2 scanners, diagnostic tools, and educational resources to help you keep your car running smoothly.

FAQ

Can you read fuel pressure with a scanner?

Yes, but only with advanced OBD2 scanners capable of accessing live data streams, like the Foxwell NT650 Elite or GT60. Basic OBD2 scanners typically can’t read fuel pressure. According to Bosch Automotive, advanced scanners provide access to more specific data parameters.

Will a fuel pump show up on a code reader?

Not directly. A standard code reader might detect issues related to the fuel system, such as lean or rich fuel conditions, but it won’t specifically identify fuel pump pressure issues. The National Institute for Automotive Service Excellence (ASE) confirms that code readers detect system-related issues rather than direct component failures.

How to test your fuel pump pressure?

You can test fuel pump pressure using a manual fuel pressure gauge that connects to your fuel system or by using an advanced diagnostic tool that can read this data from your vehicle’s ECU. According to a study by SAE International, both methods provide accurate readings for fuel pump pressure testing.

Ready to take control of your car’s diagnostics? Contact us at OBD2-SCANNER.EDU.VN today! Our experts are available to answer your questions and help you choose the right tools for your needs. Call us at +1 (641) 206-8880 or visit us at 123 Main Street, Los Angeles, CA 90001, United States. Let us help you unlock your vehicle’s full potential!