OBD2 plug functionality is a standardized system in modern vehicles that monitors performance and emissions, providing access to crucial diagnostic information. OBD2-SCANNER.EDU.VN specializes in leveraging OBD2 technology, offering in-depth insights into vehicle diagnostics and repair. Understanding the OBD2 system helps automotive experts enhance vehicle performance, streamline diagnostics, and reduce repair times, allowing for more efficient and effective vehicle maintenance.

Contents

- 1. What is OBD2 and How Does It Enhance Vehicle Diagnostics?

- 2. How Does the OBD2 Plug Work? A Detailed Technical Overview

- 3. OBD2 Port Compatibility: Ensuring Your Vehicle Can Connect

- 4. How Does an OBD2 Scanner Work? Unleashing Diagnostic Power

- 5. Beyond Basic Codes: Advanced OBD2 Data Logging Explained

- 6. How Does OBD2 Log Data? The Process of Monitoring Vehicle Health

- 7. Understanding OBD2 and CAN Bus Connection for Efficient Diagnostics

- 8. The Five OBD2 Signal Protocols: Ensuring Proper Communication

- 8.1 SAE J1850 PWM

- 8.2 SAE J1850 VPW

- 8.3 ISO 9141-2

- 8.4 ISO 14230 KWP2000

- 8.5 ISO 15765 CAN

- 9. OBD 1 vs OBD 2: Tracing the Evolution of Vehicle Diagnostics

- 10. Maximizing Vehicle Performance Through OBD2 Expertise

- FAQ: Frequently Asked Questions About OBD2 Plugs

- 1. What is an OBD2 scanner?

- 2. How do I find the OBD2 port in my car?

- 3. What types of problems can an OBD2 scanner detect?

- 4. Can I use an OBD1 scanner on an OBD2 vehicle?

- 5. Are all OBD2 scanners the same?

- 6. Do I need special training to use an OBD2 scanner?

- 7. Can an OBD2 scanner turn off the check engine light?

- 8. How often should I use an OBD2 scanner on my vehicle?

- 9. What is the CAN bus and how does it relate to OBD2?

- 10. Where can I get help with interpreting OBD2 codes?

1. What is OBD2 and How Does It Enhance Vehicle Diagnostics?

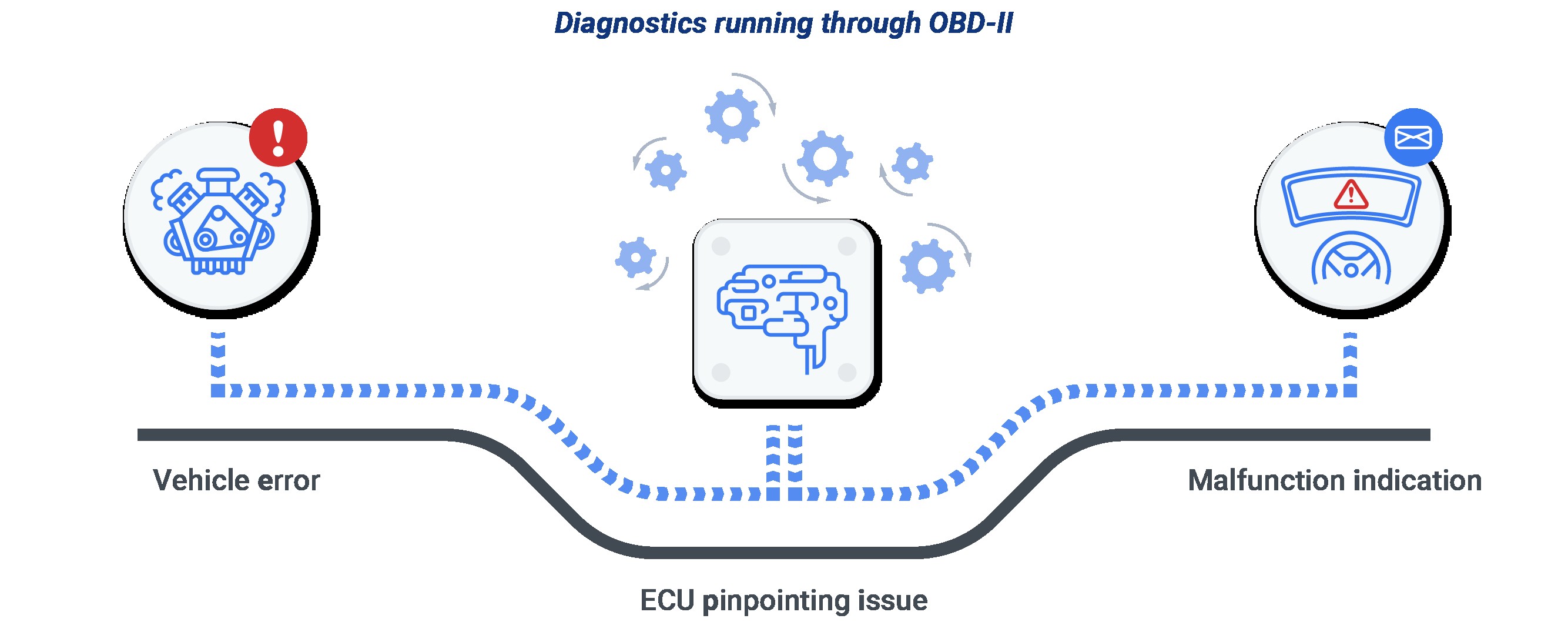

OBD2 (On-Board Diagnostics version 2) is a sophisticated diagnostic system present in virtually all cars and trucks manufactured after 1996 in the US, after 2001 in the EU, and after 2006 in Australia. It acts as the central nervous system of the vehicle, continually monitoring various components and systems for optimal performance and emissions control. When it identifies a potential issue, it alerts the driver via a check engine light on the dashboard. This proactive system is essential for early issue detection, enabling prompt repairs and preventing further damage.

The OBD2 system collects real-time data from numerous sensors located throughout the vehicle, including those in the engine, transmission, exhaust system, and more. This data is processed by the car’s Engine Control Unit (ECU), which acts as the “brain” of the vehicle. The ECU compares the sensor data against predetermined parameters, and if any discrepancies are detected, it generates Diagnostic Trouble Codes (DTCs). These codes offer valuable insights into the nature and location of the problem. According to a study by the University of California, Davis, the implementation of OBD2 systems has significantly reduced vehicle emissions by enabling faster and more accurate diagnostics.

OBD2 System Overview

OBD2 System Overview

For instance, if your vehicle experiences a sudden drop in fuel efficiency, the OBD2 system might detect a malfunctioning oxygen sensor. By identifying the issue early, you can replace the sensor before it leads to more severe engine problems or emissions violations. This proactive approach not only saves you money on potential repairs but also ensures your vehicle operates efficiently and remains compliant with environmental regulations. OBD2 systems are essential for maintaining vehicle health, reducing environmental impact, and ensuring long-term reliability.

2. How Does the OBD2 Plug Work? A Detailed Technical Overview

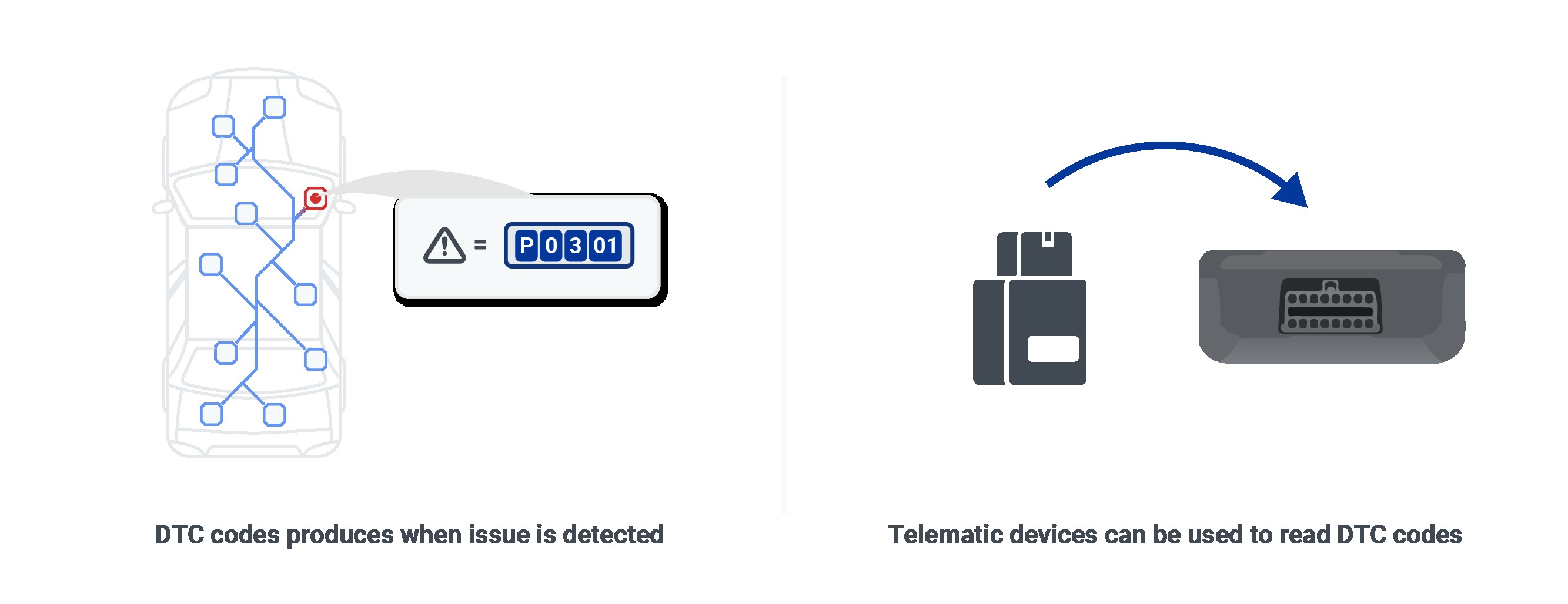

The OBD2 plug serves as the physical interface between a vehicle’s onboard computer and external diagnostic tools, enabling the extraction of critical performance and diagnostic data. When a diagnostic tool, such as an OBD2 scanner or data logger, is connected to the OBD2 port, it establishes a communication link with the vehicle’s ECU. This connection allows technicians and vehicle owners to read DTCs, monitor real-time sensor data, and perform various diagnostic tests. The OBD2 port, typically located under the dashboard, provides a standardized connection point, ensuring compatibility across different vehicle makes and models.

The OBD2 system operates by continuously monitoring data from various sensors throughout the vehicle. When the system detects a problem, it generates DTCs, which are specific codes that correspond to the detected issue. These codes can range from engine misfires and faulty sensors to problems with the transmission or emissions system. The OBD2 scanner reads these DTCs, providing a description of the problem and helping technicians pinpoint the root cause. According to research from the Society of Automotive Engineers (SAE), the standardization of OBD2 systems has significantly improved the accuracy and efficiency of vehicle diagnostics.

DTC Codes Displayed

DTC Codes Displayed

For example, if the OBD2 system detects a problem with the vehicle’s catalytic converter, it might generate a DTC such as P0420. This code indicates that the catalytic converter’s efficiency is below the acceptable threshold. A technician can then use this information to inspect the catalytic converter and related components, such as oxygen sensors and exhaust pipes, to determine the cause of the problem. Once the issue is resolved, the technician can use the OBD2 scanner to clear the DTC and reset the check engine light. The OBD2 plug’s functionality ensures that vehicles operate efficiently, meet emissions standards, and provide timely alerts for potential problems.

3. OBD2 Port Compatibility: Ensuring Your Vehicle Can Connect

Determining OBD2 compatibility is crucial for effectively diagnosing and maintaining modern vehicles. The primary factors influencing compatibility are the vehicle’s model year and the regulations in the country where it was initially sold. While the location of manufacture is irrelevant, the compliance with specific standards is paramount. In the United States, all vehicles manufactured from 1996 onwards are OBD2 compliant. In the European Union, petrol vehicles from 2001 and diesel vehicles from 2004 are OBD2 compatible. Australia followed suit in 2006, mandating OBD2 compliance for most passenger vehicles.

To quickly verify your vehicle’s OBD2 status, consult the following guidelines:

- United States: If your vehicle was manufactured in 1996 or later, it is OBD2 compliant.

- European Union: Petrol vehicles from 2001 and diesel vehicles from 2004 are OBD2 compatible.

- Japan: Most Japanese Domestic Market (JDM) vehicles comply with OBD2 standards from 2002 onwards.

- Australia: Passenger vehicles from 2006 onwards are generally OBD2 compliant.

- Canada: Vehicles in Canada align closely with US standards, adopting OBD2 in 1998 for gasoline vehicles.

However, these are general guidelines. Specific models or manufacturer practices may influence compatibility. Always consult your vehicle’s manual or contact a dealership for the most accurate information. For example, some early hybrid vehicles might have unique diagnostic protocols that require specialized equipment. Similarly, certain luxury brands may incorporate proprietary diagnostic features that are not accessible through standard OBD2 scanners. By verifying OBD2 compatibility, you ensure the proper functioning of diagnostic tools, facilitating accurate and efficient vehicle maintenance.

4. How Does an OBD2 Scanner Work? Unleashing Diagnostic Power

An OBD2 scanner is a vital tool for modern automotive diagnostics, allowing technicians and vehicle owners to access and interpret data from a vehicle’s onboard computer. This device connects to the OBD2 port, typically located under the dashboard, and communicates with the vehicle’s Engine Control Unit (ECU) to retrieve Diagnostic Trouble Codes (DTCs), monitor real-time sensor data, and perform various diagnostic tests. Understanding how to effectively use an OBD2 scanner can significantly improve your ability to diagnose and address vehicle issues, preventing major repairs and keeping your vehicle in optimal condition.

When connected, the OBD2 scanner sends a request to the vehicle’s ECU for diagnostic information. The ECU responds by transmitting DTCs, which are codes that correspond to specific issues detected by the vehicle’s sensors. The scanner displays these codes along with a brief description of the problem. Some advanced scanners also provide additional information, such as possible causes of the issue, repair tips, and access to technical service bulletins. According to a report by the National Institute for Automotive Service Excellence (ASE), technicians who use OBD2 scanners are able to diagnose and repair vehicles more quickly and accurately.

For example, if your vehicle’s check engine light is illuminated, you can connect an OBD2 scanner to retrieve the DTCs. A common code is P0300, which indicates a random or multiple cylinder misfire. The scanner might also provide additional information, such as which cylinders are misfiring and the frequency of the misfires. With this information, you can inspect the ignition system, fuel injectors, and other engine components to identify the cause of the misfire. Once the issue is resolved, you can use the scanner to clear the DTC and turn off the check engine light. OBD2 scanners are indispensable tools for proactive vehicle maintenance, enabling efficient diagnostics and timely repairs.

5. Beyond Basic Codes: Advanced OBD2 Data Logging Explained

While basic OBD2 scanners are excellent for reading and clearing Diagnostic Trouble Codes (DTCs), advanced data logging capabilities offer a deeper dive into a vehicle’s performance and health. Data logging involves recording real-time data from various sensors and systems within the vehicle over a period of time. This data can then be analyzed to identify trends, diagnose intermittent problems, and optimize vehicle performance. Advanced data logging is particularly useful for diagnosing complex issues that do not trigger DTCs or for monitoring the performance of modified vehicles.

Advanced OBD2 data loggers, such as the AutoPi CAN FD Pro, connect directly to the vehicle’s CAN bus system, providing access to a wider range of data parameters than standard OBD2 scanners. These parameters can include engine RPM, vehicle speed, throttle position, fuel consumption, oxygen sensor readings, and much more. By recording and analyzing this data, technicians can gain a comprehensive understanding of the vehicle’s operation under different conditions. According to a study by the University of Michigan Transportation Research Institute, data logging can significantly improve the accuracy of vehicle diagnostics and reduce the time required to identify and resolve complex issues.

OBD2 Data Logging Interface

OBD2 Data Logging Interface

For example, if you are experiencing intermittent engine hesitation, a standard OBD2 scanner might not provide any useful information. However, by using an advanced data logger, you can record data while driving under various conditions. Analyzing the data might reveal that the engine hesitation occurs when the throttle position sensor (TPS) reaches a certain value. This information can then be used to diagnose a faulty TPS or a problem with the wiring to the TPS. Advanced data logging capabilities enable technicians to go beyond basic error codes, providing a detailed view of vehicle performance and facilitating more accurate and efficient diagnostics.

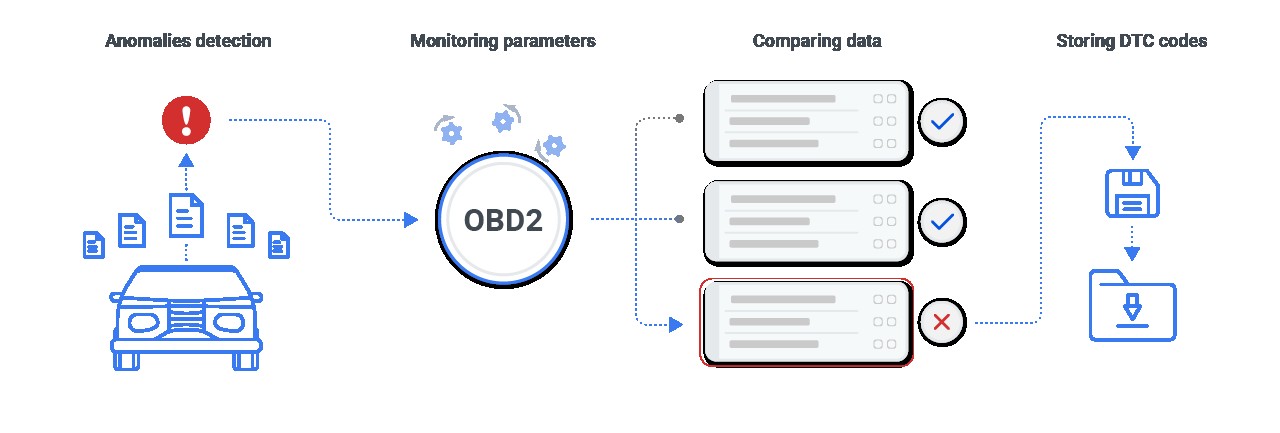

6. How Does OBD2 Log Data? The Process of Monitoring Vehicle Health

The OBD2 system continuously monitors various parameters within the vehicle to ensure optimal performance and emissions control. As it collects data from numerous sensors, it compares this information to pre-set standards. When any discrepancies or anomalies are detected, the system flags these as potential issues, translating them into Diagnostic Trouble Codes (DTCs). These codes are then stored within the onboard computer, ready to be accessed by diagnostic tools. The process of data logging involves recording and analyzing this data to identify trends, diagnose problems, and optimize vehicle performance.

The OBD2 system uses a variety of sensors to monitor different aspects of the vehicle’s operation. These sensors include oxygen sensors, mass airflow sensors, throttle position sensors, and many more. Each sensor provides real-time data to the vehicle’s Engine Control Unit (ECU), which compares the data against pre-set parameters. If the ECU detects that a parameter is outside of the acceptable range, it generates a DTC and stores it in memory. According to the Environmental Protection Agency (EPA), the OBD2 system is designed to detect and report any issues that could affect vehicle emissions, ensuring compliance with environmental regulations.

OBD2 Data Logging Diagram

OBD2 Data Logging Diagram

For example, if the oxygen sensor detects that the air-fuel mixture is too lean, the ECU will generate a DTC such as P0171 (System Too Lean, Bank 1). This code indicates that the engine is not receiving enough fuel, which could be caused by a variety of issues, such as a faulty fuel injector, a vacuum leak, or a problem with the fuel pump. By reading the DTC and analyzing the real-time data from the oxygen sensor, a technician can diagnose the cause of the problem and perform the necessary repairs. The OBD2 system’s data logging capabilities provide valuable insights into vehicle performance, enabling proactive maintenance and preventing more serious issues from developing.

7. Understanding OBD2 and CAN Bus Connection for Efficient Diagnostics

The connection between OBD2 and the CAN (Controller Area Network) bus is fundamental to modern vehicle diagnostics, as OBD2 serves as a higher-level protocol while CAN acts as its primary communication method. The CAN bus is a robust, high-speed communication network that allows various electronic control units (ECUs) within the vehicle to communicate with each other. Since 1996, the CAN bus has been an essential OBD2 protocol for all vehicles in the U.S. By 2001, Europe mandated all cars to be OBD2 compliant, and this became a requirement in Australia and New Zealand starting 2006.

The OBD2 standard defines a distinct connector, encompassing five main protocols, but the CAN bus has become the dominant protocol due to its speed and reliability. When a diagnostic tool connects to the OBD2 port, it communicates with the vehicle’s ECU via the CAN bus to retrieve Diagnostic Trouble Codes (DTCs), monitor real-time data, and perform diagnostic tests. According to Bosch, the CAN bus system allows for efficient and reliable communication between the various ECUs in a vehicle, improving overall vehicle performance and diagnostics.

For example, when a technician connects an OBD2 scanner to the vehicle, the scanner sends a request for DTCs to the ECU via the CAN bus. The ECU then transmits the DTCs back to the scanner, which displays them along with a description of the problem. The CAN bus also allows the scanner to monitor real-time data from various sensors, such as engine RPM, vehicle speed, and oxygen sensor readings. This real-time data can be used to diagnose a wide range of issues, from engine misfires to transmission problems. The integration of OBD2 and the CAN bus ensures that technicians have access to the data they need to diagnose and repair modern vehicles efficiently.

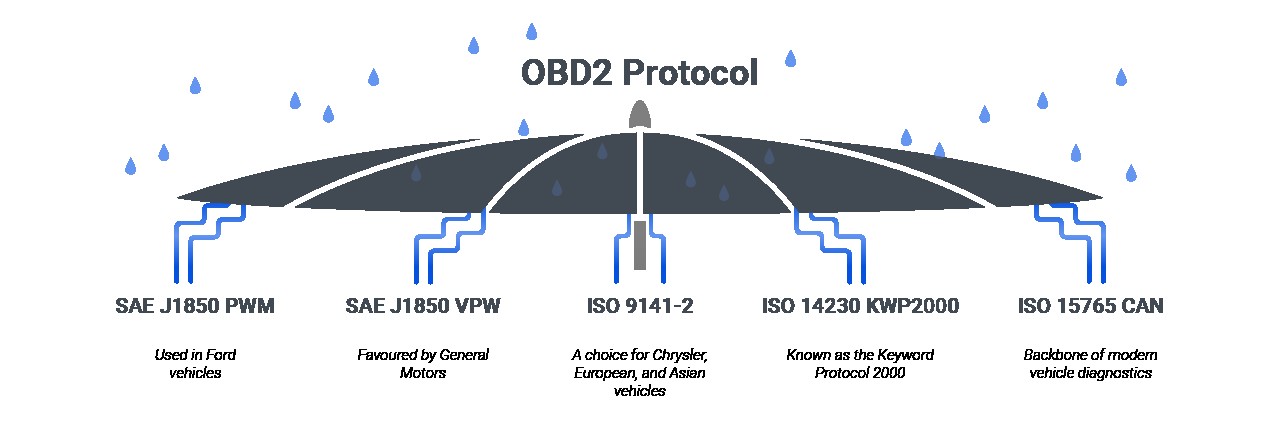

8. The Five OBD2 Signal Protocols: Ensuring Proper Communication

Diving into the world of car diagnostics, it’s essential to understand that the OBD2 system isn’t a one-size-fits-all solution. Think of the OBD2 system as the main artery of communication in your vehicle, but with five different “dialects” under the OBD2 umbrella. Each protocol has its own unique characteristics and requirements, making it crucial to select the correct protocol for proper communication between the diagnostic tool and the vehicle’s ECU. These five protocols are SAE J1850 PWM, SAE J1850 VPW, ISO 9141-2, ISO 14230 KWP2000, and ISO 15765 CAN.

The reason for having multiple protocols is rooted in the evolution of automotive technology and the need to support different vehicle makes and models. Each protocol has its own pin configuration, voltage levels, and data transmission speeds. Using the wrong protocol can result in communication errors or even damage to the vehicle’s ECU. According to the Society of Automotive Engineers (SAE), understanding these protocols is essential for automotive technicians to effectively diagnose and repair modern vehicles.

8.1 SAE J1850 PWM

Primarily used in Ford vehicles, this protocol communicates at 41.6 kbps, using Pulse Width Modulation to ensure reliable data transmission between the vehicle’s systems and diagnostic tools.

| Feature | Description |

|---|---|

| SAE J1850 PWM (Ford) | Bus +: Pin 2, Bus -: Pin 10, 12V: Pin 16, GND: Pins 4, 5, State: Active when BUS + HIGH, BUS – LOW, Voltage: Max 5V, Min 0V, Bytes: 12, Bit Timing: ‘1’ bit – 8uS, ‘0’ bit – 16uS, Start of Frame – 48uS |

8.2 SAE J1850 VPW

Favored by General Motors, it operates at speeds of 10.4/31.6 kbps with a Variable Pulse Width, offering a unique method for data exchange that enhances diagnostic efficiency.

| Feature | Description |

|---|---|

| SAE J1850 VPW (GM) | Bus +: Pin 2, 12V: Pin 16, GND: Pins 4, 5, State: Idles low, Voltage: Max +7V, Decision +3.5V, Min 0V, Bytes: 12, Bit Timing: ‘1’ bit – HIGH 64uS, ‘0’ bit – HIGH 128uS, Start of Frame – HIGH 200uS |

8.3 ISO 9141-2

A choice for Chrysler, European, and Asian vehicles, this protocol facilitates asynchronous serial communication at 10.4 kbps, similar to RS-232, but with automotive-specific signal levels for broad compatibility.

| Feature | Description |

|---|---|

| ISO 9141-2 (Chrysler, Euro, Asian) | K Line: Pin 7, L Line (optional): Pin 15, 12V: Pin 16, GND: Pins 4, 5, State: K Line idles HIGH, active when LOW, Voltage: Max +12V, Min 0V, Bytes: Message 260, Data 255, Bit Timing: UART 10400bps, 8-N-1 |

8.4 ISO 14230 KWP2000

Also known as the Keyword Protocol 2000, it extends the capabilities of ISO 9141-2 by offering speeds up to 10.4 kbps and supports a wide range of vehicle diagnostic operations, especially in Chrysler, European, and Asian models.

| Feature | Description |

|---|---|

| ISO 14230 KWP2000 (Chrysler, Euro, Asian) | K Line: Pin 7, L Line (optional): Pin 15, 12V: Pin 16, GND: Pins 4, 5, State: Active when LOW, Voltage: Max +12V, Min 0V, Bytes: Data 255, Bit Timing: UART 10400bps, 8-N-1 |

8.5 ISO 15765 CAN

The backbone of modern vehicle diagnostics, this protocol is mandatory for all vehicles sold in the US from 2008 onwards. Operating at 250 kbit/s or 500 kbit/s, it leverages the CAN bus system for high-speed, robust data communication across the vehicle’s network.

| Feature | Description |

|---|---|

| ISO 15765 CAN (US 2008+, Euro 2003+) | CAN HIGH (H): Pin 6, CAN LOW (L): Pin 14, 12V: Pin 16, GND: Pins 4, 5, State: Active CANH HIGH, CANL LOW, Idle floating, Voltage: CANH Max +4.5V, Min +2.75V; CANL Max +2.25V, Min +0.5V, Bit Timing: 250kbit/sec or 500kbit/sec |

For example, if you are working on a Ford vehicle from the early 2000s, you would need to use a diagnostic tool that supports the SAE J1850 PWM protocol. Similarly, if you are working on a modern vehicle from 2008 or later, you would need to use a tool that supports the ISO 15765 CAN protocol. Understanding these protocols and selecting the correct tool ensures accurate and efficient vehicle diagnostics.

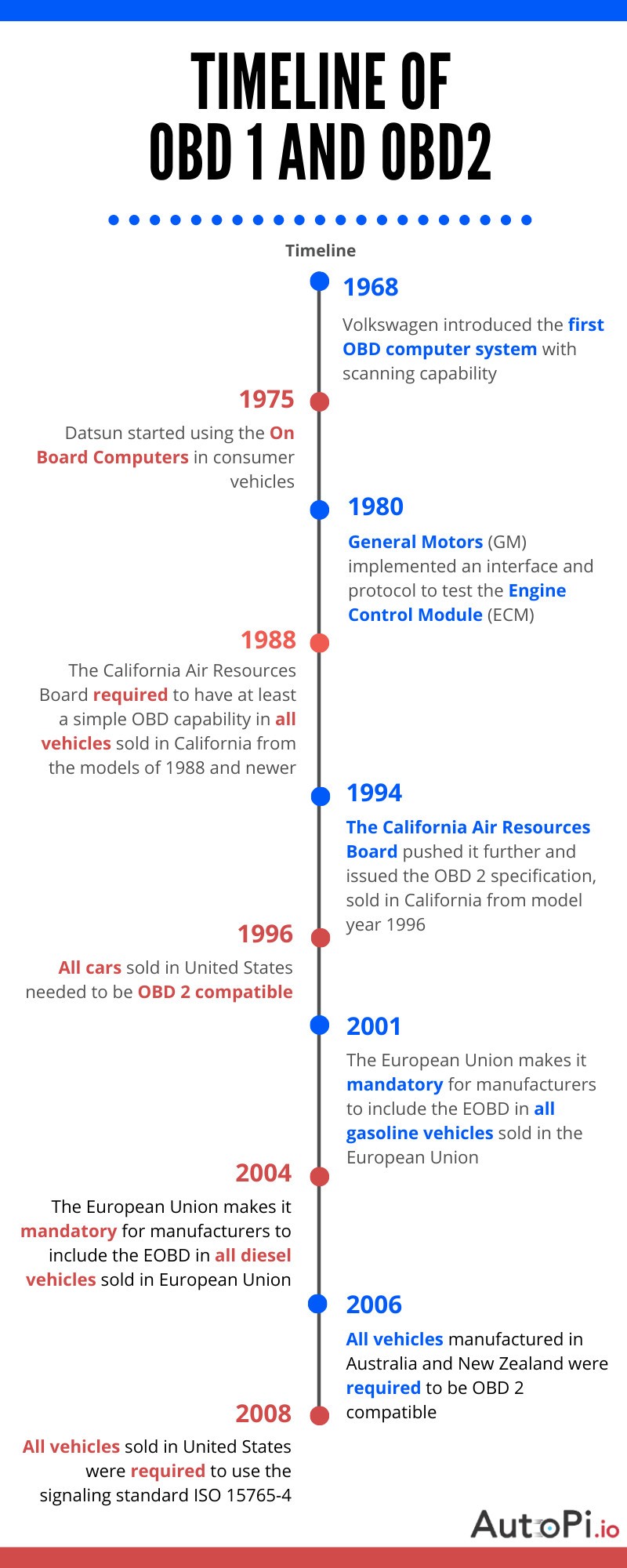

9. OBD 1 vs OBD 2: Tracing the Evolution of Vehicle Diagnostics

The evolution of On-Board Diagnostics (OBD) systems has been significant, transforming from basic, manufacturer-specific tools to standardized, comprehensive systems that monitor a wide range of vehicle functions. OBD1, developed in the 1960s, offered rudimentary diagnostics, primarily focused on emissions control. However, OBD1 systems were manufacturer-specific, meaning each car maker used different connectors, protocols, and diagnostic codes. This lack of standardization made it difficult for technicians to diagnose and repair vehicles from different manufacturers.

In contrast, OBD2, mandated in the US since 1996, provides a standardized system that enhances compatibility across manufacturers, tracks various sensor data, stores fault codes for intermittent issues, and facilitates precise real-time troubleshooting. OBD2 systems use a standard 16-pin connector and a set of standardized diagnostic codes, making it easier for technicians to diagnose and repair vehicles from different manufacturers. According to the National Highway Traffic Safety Administration (NHTSA), the standardization of OBD2 systems has improved vehicle safety and reduced emissions.

OBD1 vs OBD2 Comparison

OBD1 vs OBD2 Comparison

The advantages of OBD2 systems include enhanced fuel efficiency, early malfunction detection, cost savings through proactive maintenance, emission control compliance, and improved vehicle safety. For example, OBD2 systems can detect a malfunctioning oxygen sensor, which can reduce fuel efficiency and increase emissions. By replacing the sensor, you can improve fuel efficiency, reduce emissions, and prevent more serious engine problems. The evolution from OBD1 to OBD2 represents a significant advancement in vehicle diagnostics, providing technicians and vehicle owners with the tools they need to maintain and repair modern vehicles effectively.

10. Maximizing Vehicle Performance Through OBD2 Expertise

Understanding and utilizing OBD2 technology is crucial for maintaining vehicle health, whether you are a developer, fleet manager, or vehicle owner. OBD2 systems provide comprehensive diagnostics, monitoring a wide range of vehicle functions and offering early detection of potential issues. By leveraging OBD2, you can enhance fuel efficiency, ensure compliance with emission standards, and maintain overall vehicle safety. With tools like OBD2 scanners and vehicle telematics devices, diagnosing and addressing vehicle performance issues becomes more efficient and effective, ultimately leading to significant cost savings and extended vehicle lifespan.

OBD2 technology allows for proactive vehicle maintenance, enabling you to identify and address potential issues before they escalate into major problems. For example, by monitoring real-time data from the oxygen sensors, you can detect a lean or rich fuel mixture, which can indicate a problem with the fuel injectors, mass airflow sensor, or other engine components. By addressing these issues early, you can prevent engine damage and maintain optimal fuel efficiency. According to a study by the American Automobile Association (AAA), proactive vehicle maintenance can save drivers an average of $300 per year in repair costs.

OBD2-SCANNER.EDU.VN is dedicated to providing automotive experts with the knowledge and resources they need to maximize vehicle performance through OBD2 technology. Whether you need assistance with diagnosing a complex issue, optimizing fuel efficiency, or ensuring compliance with emission standards, our team of experts is here to help. Contact us today at 123 Main Street, Los Angeles, CA 90001, United States, or via WhatsApp at +1 (641) 206-8880, or visit our website at OBD2-SCANNER.EDU.VN. Let us help you harness the power of OBD2 technology to keep your vehicles running smoothly and reliably.

Do you want to understand how the OBD2 plug works and how it can benefit your vehicle maintenance? Contact OBD2-SCANNER.EDU.VN today for expert advice and service. Our experienced technicians are ready to assist you with all your OBD2-related questions. Reach us at 123 Main Street, Los Angeles, CA 90001, United States, or via WhatsApp at +1 (641) 206-8880, or visit our website at OBD2-SCANNER.EDU.VN.

FAQ: Frequently Asked Questions About OBD2 Plugs

1. What is an OBD2 scanner?

An OBD2 scanner is a diagnostic tool used to read and interpret data from a vehicle’s onboard computer system. It connects to the OBD2 port, typically located under the dashboard, and retrieves Diagnostic Trouble Codes (DTCs) that indicate potential issues within the vehicle. These scanners provide valuable information for diagnosing and repairing vehicle problems.

2. How do I find the OBD2 port in my car?

The OBD2 port is typically located under the dashboard on the driver’s side of the vehicle. It is usually within easy reach and may be covered by a small plastic panel. Refer to your vehicle’s owner’s manual for the exact location if you are unsure.

3. What types of problems can an OBD2 scanner detect?

An OBD2 scanner can detect a wide range of problems, including engine misfires, faulty sensors, emissions system issues, transmission problems, and more. It provides Diagnostic Trouble Codes (DTCs) that help pinpoint the source of the issue.

4. Can I use an OBD1 scanner on an OBD2 vehicle?

No, OBD1 scanners are not compatible with OBD2 vehicles. OBD2 systems use a standardized 16-pin connector and different communication protocols than OBD1 systems. Attempting to connect an OBD1 scanner to an OBD2 vehicle can result in damage to the vehicle’s computer system.

5. Are all OBD2 scanners the same?

No, OBD2 scanners vary in features and capabilities. Basic scanners can read and clear Diagnostic Trouble Codes (DTCs), while advanced scanners offer additional features such as real-time data monitoring, graphing, and access to technical service bulletins.

6. Do I need special training to use an OBD2 scanner?

While basic OBD2 scanners are relatively easy to use, advanced scanners may require some training or experience to interpret the data effectively. Many resources are available online and through automotive repair shops to help you learn how to use an OBD2 scanner.

7. Can an OBD2 scanner turn off the check engine light?

Yes, an OBD2 scanner can turn off the check engine light by clearing the Diagnostic Trouble Codes (DTCs) that triggered the light. However, if the underlying issue is not resolved, the check engine light will likely reappear.

8. How often should I use an OBD2 scanner on my vehicle?

You should use an OBD2 scanner whenever the check engine light comes on or if you suspect a problem with your vehicle’s performance. Regular use of an OBD2 scanner can help you identify and address potential issues before they become major problems.

9. What is the CAN bus and how does it relate to OBD2?

The CAN (Controller Area Network) bus is a high-speed communication network that allows various electronic control units (ECUs) within the vehicle to communicate with each other. OBD2 systems use the CAN bus to access and interpret data from these ECUs.

10. Where can I get help with interpreting OBD2 codes?

You can get help with interpreting OBD2 codes from various sources, including online forums, automotive repair shops, and diagnostic code databases. Additionally, OBD2-SCANNER.EDU.VN offers expert assistance and resources to help you understand and address OBD2 codes. Contact us at 123 Main Street, Los Angeles, CA 90001, United States, or via WhatsApp at +1 (641) 206-8880, or visit our website at OBD2-SCANNER.EDU.VN for more information.