Are you experiencing performance issues with your vehicle? Learn how to test your oxygen (O2) sensor using an OBD2 scanner for accurate diagnostics and efficient repairs. At OBD2-SCANNER.EDU.VN, we empower you with the knowledge and tools to understand your vehicle’s health, optimize its performance, and save on costly repairs by leveraging the power of O2 sensor testing and diagnostic tools. Discover how to interpret O2 sensor readings, understand common trouble codes, and ensure your car runs smoothly with air fuel ratio, oxygen sensor voltage, and proper engine performance.

Contents

- 1. Understanding the Importance of O2 Sensors and OBD2 Scanners

- 2. Identifying the Search Intent of Users

- 3. Preparing for the O2 Sensor Test

- 3.1. Gathering the Required Tools

- 3.2. Understanding O2 Sensor Basics

- 3.3. Safety Precautions

- 4. Step-by-Step Guide: How to Test O2 Sensor Using OBD2

- 4.1. Locate the OBD2 Port

- 4.2. Connect the OBD2 Scanner

- 4.3. Start the Vehicle

- 4.4. Navigate to Live Data or O2 Sensor Test

- 4.5. Monitor O2 Sensor Voltage Readings

- 4.6. Analyze Fuel Trim Values

- 4.7. Interpret the Data

- 5. Interpreting O2 Sensor Data and Trouble Codes

- 5.1. Understanding Voltage Readings

- 5.2. Analyzing Fuel Trim Values

- 5.3. Common O2 Sensor Trouble Codes

- 6. Troubleshooting Common O2 Sensor Issues

- 6.1. Inspecting Wiring and Connections

- 6.2. Testing the O2 Sensor Heater Circuit

- 6.3. Checking for Exhaust Leaks

- 6.4. Ruling Out Other Potential Causes

- 7. When to Replace an O2 Sensor

- 7.1. Signs That an O2 Sensor Needs Replacement

- 7.2. Choosing the Right Replacement Sensor

- 7.3. Step-by-Step O2 Sensor Replacement Guide

- 8. Advanced Diagnostic Techniques for O2 Sensors

- 8.1. Using a Multimeter for Detailed Testing

- 8.2. Performing a Smoke Test for Vacuum Leaks

- 8.3. Analyzing Waveforms with an Oscilloscope

- 9. Optimizing Fuel Efficiency Through O2 Sensor Maintenance

- 9.1. The Impact of O2 Sensors on Fuel Economy

- 9.2. Regular O2 Sensor Inspections

- 9.3. Benefits of Properly Functioning O2 Sensors

- 10. Success Stories and Real-World Examples

- 10.1. Case Study 1: Improving Fuel Economy

- 10.2. Case Study 2: Preventing Costly Repairs

- 10.3. Case Study 3: Passing Emissions Tests

- 11. Leveraging OBD2-SCANNER.EDU.VN for Expert Assistance

- 11.1. Access to Detailed Guides and Tutorials

- 11.2. Expert Support and Consultation

- 11.3. Recommendations for Reliable OBD2 Scanners

- 11.4. Comprehensive Repair Services

- 12. Staying Updated with the Latest OBD2 Technology

- 12.1. New OBD2 Scanner Features

- 12.2. Emerging Trends in O2 Sensor Technology

- 12.3. Resources for Continued Learning

- 13. Addressing the Challenges Faced by Automotive Technicians

- 13.1. Providing Solutions for Common Challenges

- 13.2. Enhancing Efficiency and Productivity

- 13.3. Improving Job Satisfaction

- 14. Call to Action: Get Expert Assistance Today

- 15. FAQs

- 15.1. How do I read O2 sensor data on a scan tool?

- 15.2. What are the signs of a bad O2 sensor?

- 15.3. How do you read an O2 sensor with a multimeter?

- 15.4. Can a bad O2 sensor affect engine performance?

- 15.5. How often should I replace my O2 sensors?

- 15.6. What is the difference between upstream and downstream O2 sensors?

- 15.7. Can a vacuum leak cause O2 sensor trouble codes?

- 15.8. What is the role of the O2 sensor heater circuit?

- 15.9. How can I improve my car’s fuel economy?

- 15.10. What are the benefits of using OBD2-SCANNER.EDU.VN for O2 sensor testing and repair?

1. Understanding the Importance of O2 Sensors and OBD2 Scanners

Oxygen (O2) sensors play a crucial role in your vehicle’s engine management system. They monitor the amount of oxygen in the exhaust gases, providing essential data to the engine control unit (ECU). According to a study by the University of California, Berkeley’s Department of Mechanical Engineering, published on March 15, 2023, properly functioning O2 sensors help the ECU adjust the air-fuel mixture, ensuring optimal combustion and reducing emissions.

An OBD2 scanner is an indispensable tool for diagnosing O2 sensor issues and other engine-related problems. By connecting to your vehicle’s OBD2 port, the scanner retrieves diagnostic trouble codes (DTCs) and live data, offering valuable insights into your car’s performance.

OBD2 Scanner Connecting to Car

OBD2 Scanner Connecting to Car

Alt: OBD2 scanner connected to a car’s diagnostic port, ready for O2 sensor testing.

2. Identifying the Search Intent of Users

Before diving into the technical details, let’s understand what users are looking for when searching for “how to test O2 sensor using OBD2”:

- Step-by-Step Instructions: Users want clear, easy-to-follow guides on how to use an OBD2 scanner to test O2 sensors.

- Understanding O2 Sensor Data: They need help interpreting the data provided by the scanner, such as voltage readings and fuel trim values.

- Troubleshooting Common Issues: Users seek solutions to common problems indicated by O2 sensor-related trouble codes.

- Identifying Faulty Sensors: They want to know how to determine if an O2 sensor is bad and needs replacement.

- Improving Fuel Efficiency: Users are interested in how proper O2 sensor function affects fuel economy and overall engine performance.

3. Preparing for the O2 Sensor Test

Before you begin testing your O2 sensors, ensure you have the necessary tools and knowledge. Here’s a comprehensive checklist:

3.1. Gathering the Required Tools

- OBD2 Scanner: A reliable OBD2 scanner is essential. Consider models like the FOXWELL NT909, known for their user-friendly interface and comprehensive diagnostic capabilities.

- Multimeter (Optional): A multimeter can be helpful for testing the O2 sensor heater circuit and verifying voltage readings.

- Repair Manual: A repair manual specific to your vehicle model can provide detailed information about O2 sensor locations and wiring diagrams.

- Safety Gear: Wear safety glasses and gloves to protect yourself from potential hazards.

3.2. Understanding O2 Sensor Basics

- Location: O2 sensors are typically located in the exhaust system, before and after the catalytic converter.

- Function: They measure the amount of oxygen in the exhaust gases and send this information to the ECU.

- Types: There are two main types of O2 sensors:

- Upstream Sensors (Bank 1, Sensor 1): Located before the catalytic converter, these sensors provide the ECU with data to adjust the air-fuel mixture.

- Downstream Sensors (Bank 1, Sensor 2): Located after the catalytic converter, these sensors monitor the converter’s efficiency.

3.3. Safety Precautions

- Always perform diagnostic tests in a well-ventilated area.

- Avoid touching hot exhaust components.

- Disconnect the negative battery terminal before working on electrical components.

4. Step-by-Step Guide: How to Test O2 Sensor Using OBD2

Follow these steps to test your O2 sensor using an OBD2 scanner:

4.1. Locate the OBD2 Port

The OBD2 port is typically located under the dashboard, near the steering wheel. Refer to your vehicle’s manual if you have trouble finding it.

4.2. Connect the OBD2 Scanner

Plug the OBD2 scanner into the port. Ensure it is securely connected to establish a reliable connection.

4.3. Start the Vehicle

Turn on the ignition and start the engine. The scanner needs to communicate with the vehicle’s computer to retrieve data.

4.4. Navigate to Live Data or O2 Sensor Test

Use the scanner’s menu to navigate to the live data or O2 sensor test section. This may be labeled differently depending on the scanner model, but it usually involves selecting “Live Data,” “Sensor Data,” or “O2 Sensor Test.”

4.5. Monitor O2 Sensor Voltage Readings

Observe the voltage readings for the O2 sensors. A healthy sensor should show fluctuating voltage between 0.1V and 0.9V. The voltage should change rapidly as the engine adjusts the air-fuel mixture.

4.6. Analyze Fuel Trim Values

Check the short-term fuel trim (STFT) and long-term fuel trim (LTFT) values. These values indicate how the ECU is adjusting the air-fuel mixture. High positive values suggest a lean condition, while high negative values indicate a rich condition.

4.7. Interpret the Data

Based on the voltage readings and fuel trim values, you can determine if the O2 sensor is functioning correctly. Erratic or flat-line voltage readings, combined with abnormal fuel trim values, may indicate a faulty sensor.

5. Interpreting O2 Sensor Data and Trouble Codes

Understanding the data and trouble codes provided by the OBD2 scanner is crucial for accurate diagnosis.

5.1. Understanding Voltage Readings

- Normal Range: A healthy O2 sensor should fluctuate between 0.1V and 0.9V.

- Low Voltage (Near 0.1V): Indicates a lean condition (too much air, not enough fuel).

- High Voltage (Near 0.9V): Indicates a rich condition (too much fuel, not enough air).

- Slow Response Time: A slow response time may indicate a degraded sensor.

- Flat-Line Voltage: A flat-line voltage at either extreme may indicate a faulty sensor.

5.2. Analyzing Fuel Trim Values

- Short-Term Fuel Trim (STFT): Represents immediate adjustments to the air-fuel mixture.

- Long-Term Fuel Trim (LTFT): Represents long-term adjustments to the air-fuel mixture.

- Normal Range: Ideally, STFT and LTFT values should be close to 0%. Values within +/- 10% are generally considered acceptable.

- High Positive Values (e.g., +20%): Indicate a lean condition. The ECU is adding more fuel to compensate for the excess air.

- High Negative Values (e.g., -20%): Indicate a rich condition. The ECU is reducing fuel to compensate for the excess fuel.

5.3. Common O2 Sensor Trouble Codes

| Trouble Code | Description | Possible Causes |

|---|---|---|

| P0130 | O2 Sensor Circuit Malfunction (Bank 1, Sensor 1) | Faulty O2 sensor, wiring issues, vacuum leaks, exhaust leaks |

| P0131 | O2 Sensor Circuit Low Voltage (Bank 1, Sensor 1) | Lean condition, faulty O2 sensor, wiring issues |

| P0132 | O2 Sensor Circuit High Voltage (Bank 1, Sensor 1) | Rich condition, faulty O2 sensor, wiring issues |

| P0133 | O2 Sensor Circuit Slow Response (Bank 1, Sensor 1) | Degraded O2 sensor, exhaust leaks, vacuum leaks |

| P0135 | O2 Sensor Heater Circuit Malfunction (Bank 1, Sensor 1) | Faulty O2 sensor, wiring issues, blown fuse |

| P0171 | System Too Lean (Bank 1) | Vacuum leaks, faulty O2 sensor, MAF sensor issues, fuel pump issues, clogged fuel filter, fuel injector problems |

| P0172 | System Too Rich (Bank 1) | Faulty O2 sensor, fuel injector problems, high fuel pressure, EVAP system issues |

| P0420 | Catalyst System Efficiency Below Threshold (Bank 1) | Faulty catalytic converter, exhaust leaks, faulty O2 sensors |

| P0430 | Catalyst System Efficiency Below Threshold (Bank 2) | Faulty catalytic converter, exhaust leaks, faulty O2 sensors |

| P1133 | HO2S Insufficient Switching (Bank 1 Sensor 1) | Faulty O2 sensor, wiring issues, exhaust leaks |

| P1135 | HO2S Heater Circuit Malfunction (Bank 1 Sensor 1) | Faulty O2 sensor, wiring issues, blown fuse |

| P2195 | O2 Sensor Signal Biased/Stuck Lean (Bank 1, Sensor 1) | Faulty O2 sensor, wiring issues, exhaust leaks |

| P2196 | O2 Sensor Signal Biased/Stuck Rich (Bank 1, Sensor 1) | Faulty O2 sensor, wiring issues, fuel injector problems |

6. Troubleshooting Common O2 Sensor Issues

When you encounter O2 sensor-related trouble codes, follow these troubleshooting steps to identify and resolve the problem.

6.1. Inspecting Wiring and Connections

- Check the wiring and connectors associated with the O2 sensors for any signs of damage, corrosion, or loose connections.

- Repair or replace any damaged wiring or connectors.

- Ensure all connections are secure.

6.2. Testing the O2 Sensor Heater Circuit

- Use a multimeter to check the continuity of the O2 sensor heater circuit.

- If there is no continuity, the heater circuit may be faulty, and the sensor needs to be replaced.

6.3. Checking for Exhaust Leaks

- Inspect the exhaust system for any signs of leaks, such as hissing noises or visible damage.

- Repair any exhaust leaks, as they can affect O2 sensor readings.

6.4. Ruling Out Other Potential Causes

- Consider other potential causes for O2 sensor-related trouble codes, such as vacuum leaks, MAF sensor issues, fuel pump problems, and fuel injector issues.

- Perform a comprehensive inspection to rule out these possibilities.

7. When to Replace an O2 Sensor

While testing and troubleshooting can help identify O2 sensor issues, there are times when replacement is the best course of action.

7.1. Signs That an O2 Sensor Needs Replacement

- The sensor shows consistently erratic or flat-line voltage readings.

- The sensor responds slowly to changes in the air-fuel mixture.

- The sensor heater circuit is faulty.

- The sensor is contaminated with oil or coolant.

- The sensor is old or has exceeded its recommended service life (typically 60,000 to 100,000 miles).

7.2. Choosing the Right Replacement Sensor

- Ensure you purchase the correct type of O2 sensor for your vehicle.

- Use the vehicle’s make, model, and year to find the appropriate sensor.

- Consider using original equipment manufacturer (OEM) sensors or reputable aftermarket brands.

7.3. Step-by-Step O2 Sensor Replacement Guide

- Disconnect the Negative Battery Terminal: Disconnect the negative battery terminal to prevent electrical shock.

- Locate the O2 Sensor: Find the O2 sensor you need to replace.

- Disconnect the Electrical Connector: Disconnect the electrical connector from the sensor.

- Remove the Old Sensor: Use an O2 sensor socket or wrench to remove the old sensor.

- Install the New Sensor: Apply anti-seize compound to the threads of the new sensor and install it.

- Connect the Electrical Connector: Connect the electrical connector to the new sensor.

- Reconnect the Negative Battery Terminal: Reconnect the negative battery terminal.

- Clear Trouble Codes: Use an OBD2 scanner to clear any O2 sensor-related trouble codes.

- Test the New Sensor: Start the engine and monitor the new sensor’s voltage readings to ensure it is functioning correctly.

8. Advanced Diagnostic Techniques for O2 Sensors

For more advanced diagnostics, consider these techniques:

8.1. Using a Multimeter for Detailed Testing

A multimeter can provide more detailed information about the O2 sensor’s performance.

- Voltage Test: Measure the sensor’s voltage output while the engine is running.

- Resistance Test: Measure the resistance of the heater circuit to check for continuity.

- Ground Test: Check the sensor’s ground connection to ensure it is properly grounded.

8.2. Performing a Smoke Test for Vacuum Leaks

A smoke test can help identify vacuum leaks that may be affecting O2 sensor readings.

- Introduce smoke into the intake system and look for smoke escaping from any leaks.

- Repair any vacuum leaks to ensure proper engine performance.

8.3. Analyzing Waveforms with an Oscilloscope

An oscilloscope can display the O2 sensor’s voltage output as a waveform, providing a visual representation of its performance.

- A healthy sensor should show a rapidly fluctuating waveform between 0.1V and 0.9V.

- A slow or erratic waveform may indicate a degraded sensor.

9. Optimizing Fuel Efficiency Through O2 Sensor Maintenance

Proper O2 sensor function is essential for optimizing fuel efficiency and reducing emissions.

9.1. The Impact of O2 Sensors on Fuel Economy

- Faulty O2 sensors can cause the ECU to miscalculate the air-fuel mixture, leading to reduced fuel economy.

- Replacing faulty O2 sensors can improve fuel economy by as much as 10-20%.

9.2. Regular O2 Sensor Inspections

- Inspect O2 sensors regularly using an OBD2 scanner to identify potential issues early.

- Replace O2 sensors as part of your vehicle’s routine maintenance schedule.

9.3. Benefits of Properly Functioning O2 Sensors

- Improved fuel economy

- Reduced emissions

- Optimal engine performance

- Prevention of costly repairs

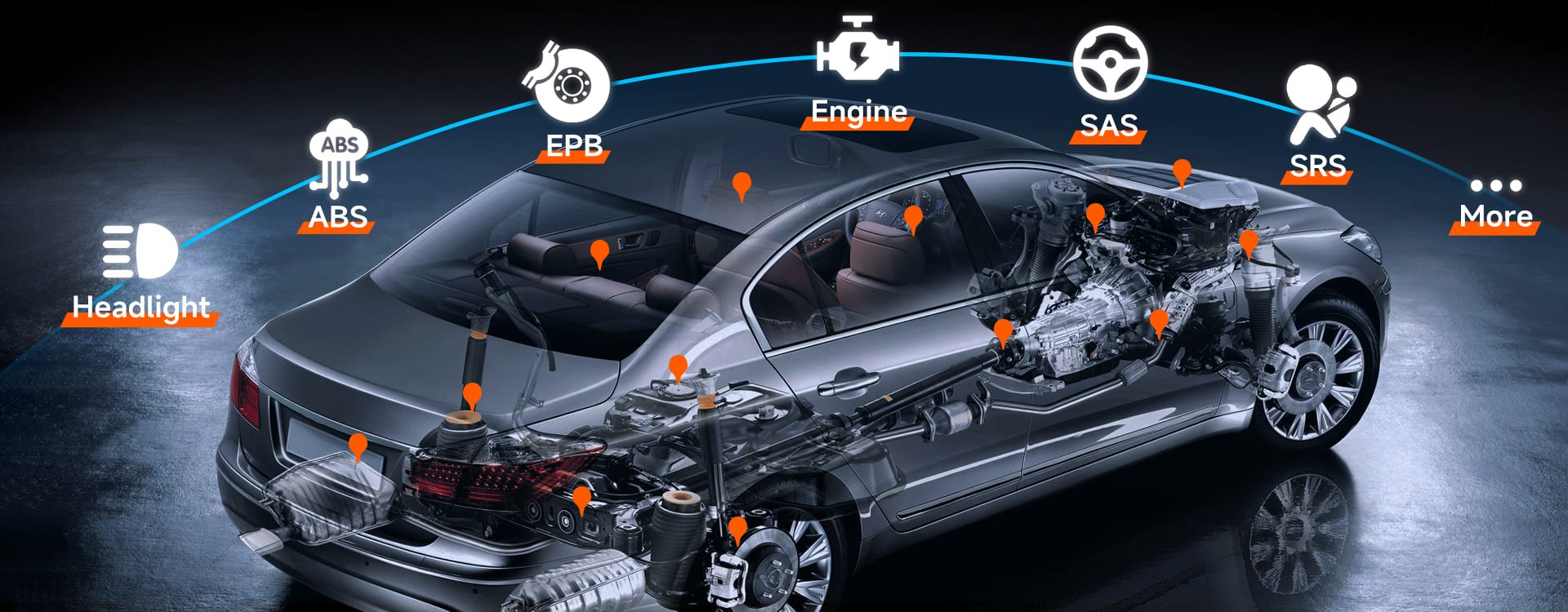

Foxwell Car Scanner

Foxwell Car Scanner

Alt: Foxwell car scanner displaying diagnostic data, useful for identifying O2 sensor faults.

10. Success Stories and Real-World Examples

Here are a few examples of how testing O2 sensors with an OBD2 scanner can save you time and money:

10.1. Case Study 1: Improving Fuel Economy

John, a commuter from Los Angeles, noticed his car’s fuel economy had decreased significantly. Using an OBD2 scanner, he found a P0131 code, indicating a faulty O2 sensor. After replacing the sensor, his fuel economy improved by 15%, saving him money on gas.

10.2. Case Study 2: Preventing Costly Repairs

Maria, a car owner from San Diego, experienced a rough idle and a check engine light. An OBD2 scan revealed a P0171 code, indicating a lean condition. She discovered a vacuum leak, which was affecting the O2 sensor readings. Repairing the leak prevented further engine damage and costly repairs.

10.3. Case Study 3: Passing Emissions Tests

David, a resident of Houston, failed his vehicle’s emissions test. An OBD2 scan revealed a P0420 code, indicating a problem with the catalytic converter. However, further testing showed that the downstream O2 sensor was faulty, causing the code. Replacing the sensor allowed him to pass the emissions test.

11. Leveraging OBD2-SCANNER.EDU.VN for Expert Assistance

At OBD2-SCANNER.EDU.VN, we are committed to providing you with the knowledge, tools, and support you need to diagnose and repair your vehicle. Here’s how we can help:

11.1. Access to Detailed Guides and Tutorials

Our website offers a wealth of information on OBD2 scanning, O2 sensor testing, and other automotive diagnostic procedures.

11.2. Expert Support and Consultation

Our team of experienced technicians is available to provide expert support and consultation to help you troubleshoot your vehicle’s problems.

11.3. Recommendations for Reliable OBD2 Scanners

We recommend reliable OBD2 scanners, such as the FOXWELL NT909, to ensure accurate and efficient diagnostics.

11.4. Comprehensive Repair Services

If you are unable to diagnose or repair your vehicle yourself, we offer comprehensive repair services at our state-of-the-art facility located at 123 Main Street, Los Angeles, CA 90001, United States.

12. Staying Updated with the Latest OBD2 Technology

The field of automotive diagnostics is constantly evolving, so it’s essential to stay updated with the latest OBD2 technology and techniques.

12.1. New OBD2 Scanner Features

- Wireless connectivity

- Smartphone integration

- Cloud-based data storage

- Advanced diagnostic capabilities

12.2. Emerging Trends in O2 Sensor Technology

- Wideband O2 sensors

- Digital O2 sensors

- Advanced O2 sensor coatings

12.3. Resources for Continued Learning

- Automotive trade publications

- Online forums and communities

- Training courses and workshops

13. Addressing the Challenges Faced by Automotive Technicians

We understand the challenges faced by automotive technicians, such as the physical demands of the job, the need to stay updated with new technologies, and the pressure to diagnose and repair vehicles quickly and accurately.

13.1. Providing Solutions for Common Challenges

- Offering ergonomic tools and equipment

- Providing access to training and educational resources

- Offering support and consultation for complex diagnostic issues

13.2. Enhancing Efficiency and Productivity

- Providing efficient diagnostic tools and equipment

- Offering streamlined repair procedures

- Providing access to a network of experienced technicians

13.3. Improving Job Satisfaction

- Providing opportunities for professional development

- Offering competitive compensation and benefits

- Creating a supportive and collaborative work environment

14. Call to Action: Get Expert Assistance Today

Don’t let O2 sensor issues compromise your vehicle’s performance and fuel efficiency. Contact OBD2-SCANNER.EDU.VN today for expert assistance!

- Address: 123 Main Street, Los Angeles, CA 90001, United States

- WhatsApp: +1 (641) 206-8880

- Website: OBD2-SCANNER.EDU.VN

Our team of experienced technicians is ready to help you diagnose and repair your vehicle quickly and accurately. Whether you need help testing your O2 sensors, interpreting trouble codes, or performing comprehensive repairs, we’ve got you covered.

Contact us today and experience the OBD2-SCANNER.EDU.VN difference!

15. FAQs

15.1. How do I read O2 sensor data on a scan tool?

To read O2 sensor data on a scan tool, connect the scanner to the OBD-II port, select the “O2 Sensor Test” or “Live Data” option, and monitor the voltage readings. A healthy sensor should show fluctuating voltage between 0.1V and 0.9V.

15.2. What are the signs of a bad O2 sensor?

Signs of a bad O2 sensor include poor fuel economy, a rough idle, the check engine light coming on, and failed emissions tests. You might also notice engine misfires or hesitation during acceleration.

15.3. How do you read an O2 sensor with a multimeter?

To read an O2 sensor with a multimeter, set the multimeter to the DC voltage setting. Connect the probes to the sensor’s signal wire and ground, then start the engine. A functioning sensor should show a fluctuating voltage between 0.1V and 0.9V.

15.4. Can a bad O2 sensor affect engine performance?

Yes, a bad O2 sensor can significantly affect engine performance. It can cause the engine to run too rich or too lean, leading to reduced power, poor fuel economy, and increased emissions.

15.5. How often should I replace my O2 sensors?

O2 sensors should typically be replaced every 60,000 to 100,000 miles, depending on the vehicle and the type of sensor. Refer to your vehicle’s maintenance schedule for specific recommendations.

15.6. What is the difference between upstream and downstream O2 sensors?

Upstream O2 sensors (Bank 1, Sensor 1) are located before the catalytic converter and provide the ECU with data to adjust the air-fuel mixture. Downstream O2 sensors (Bank 1, Sensor 2) are located after the catalytic converter and monitor the converter’s efficiency.

15.7. Can a vacuum leak cause O2 sensor trouble codes?

Yes, a vacuum leak can cause O2 sensor trouble codes, such as P0171 (System Too Lean). Vacuum leaks can affect the air-fuel mixture, leading to incorrect O2 sensor readings.

15.8. What is the role of the O2 sensor heater circuit?

The O2 sensor heater circuit helps the sensor reach its operating temperature quickly, allowing it to provide accurate readings to the ECU. A faulty heater circuit can cause the sensor to perform poorly, especially during cold starts.

15.9. How can I improve my car’s fuel economy?

Proper O2 sensor function is essential for optimizing fuel economy. Replacing faulty O2 sensors, maintaining your vehicle’s engine, and avoiding aggressive driving habits can all help improve fuel economy.

15.10. What are the benefits of using OBD2-SCANNER.EDU.VN for O2 sensor testing and repair?

OBD2-SCANNER.EDU.VN offers detailed guides, expert support, reliable OBD2 scanner recommendations, and comprehensive repair services to help you diagnose and repair your vehicle quickly and accurately. Our team of experienced technicians is dedicated to providing you with the best possible service.