How to use a digital CAN OBD2 diagnostic tool effectively is a crucial skill for modern car owners and mechanics alike, enabling swift identification and resolution of vehicle issues. At OBD2-SCANNER.EDU.VN, we empower you with the knowledge and tools to expertly diagnose and maintain your vehicle, ensuring peak performance and longevity. By understanding OBD II protocols, diagnostic procedures, and leveraging advanced scan tool features, you can unlock the full potential of your vehicle’s onboard diagnostics system.

Contents

- 1. Understanding OBD2 and CAN Protocols

- 1.1 Evolution of Vehicle Diagnostics

- 1.2 Key Differences Between OBD-I and OBD2

- 1.3 Understanding CAN Bus System

- 1.4 Advantages of Using CAN OBD2 Diagnostic Tools

- 2. Selecting the Right OBD2 Diagnostic Tool

- 2.1 Types of OBD2 Scanners Available

- 2.2 Key Features to Look For in an OBD2 Scanner

- 2.3 Compatibility with Different Vehicle Makes and Models

- 2.4 Budget Considerations for OBD2 Diagnostic Tools

- 3. Step-by-Step Guide to Using a Digital CAN OBD2 Diagnostic Tool

- 3.1 Locating the OBD2 Port in Your Vehicle

- 3.2 Connecting the OBD2 Scanner

- 3.3 Reading Diagnostic Trouble Codes (DTCs)

- 3.4 Interpreting OBD2 Trouble Codes

- 3.5 Clearing Trouble Codes

- 4. Advanced Features of Digital CAN OBD2 Diagnostic Tools

- 4.1 Live Data Streaming and Analysis

- 4.2 Freeze Frame Data

- 4.3 Bidirectional Control

- 4.4 Accessing Manufacturer-Specific Codes

- 5. Common OBD2 Error Codes and Their Meanings

- 5.1 P0300: Random Misfire Detected

- 5.2 P0171: System Too Lean

- 5.3 P0420: Catalyst System Efficiency Below Threshold

- 5.4 P0301: Cylinder 1 Misfire Detected

- 5.5 P0101: Mass Airflow Sensor Circuit Range/Performance Problem

- 6. Maintaining Your Vehicle Using OBD2 Diagnostics

- 6.1 Regular OBD2 Scans for Preventative Maintenance

- 6.2 Monitoring Vehicle Performance with Live Data

- 6.3 Addressing Potential Issues Early

- 6.4 Benefits of Regular Vehicle Maintenance

- 7. Troubleshooting Common Issues with OBD2 Diagnostic Tools

- 7.1 Connection Problems

- 7.2 Software Glitches

- 7.3 Compatibility Issues

- 7.4 Inaccurate Readings

- 8. Advanced Diagnostic Techniques with OBD2 Scanners

- 8.1 Performing Relative Compression Tests

- 8.2 Conducting Cylinder Balance Tests

1. Understanding OBD2 and CAN Protocols

What exactly are OBD2 and CAN, and why are they important for vehicle diagnostics?

OBD2 (On-Board Diagnostics II) is a standardized system that monitors a vehicle’s engine, transmission, and other critical components for malfunctions. CAN (Controller Area Network) is a communication protocol used by vehicles to allow different electronic control units (ECUs) to communicate with each other without a host computer. According to a study by the Society of Automotive Engineers (SAE), the OBD2 system provides standardized diagnostic trouble codes (DTCs) that can be read by any compatible scan tool, simplifying the diagnostic process. The CAN protocol, as highlighted in research from Bosch, enhances data transmission speed and reliability, which is essential for modern vehicle systems.

1.1 Evolution of Vehicle Diagnostics

How has vehicle diagnostics evolved, leading to the current OBD2 and CAN systems?

Vehicle diagnostics has significantly evolved from rudimentary methods to sophisticated electronic systems. Early diagnostic approaches involved manual inspections and mechanical tests. The introduction of OBD-I in the 1980s marked the initial step toward computerized diagnostics, but it lacked standardization. OBD2, introduced in the mid-1990s, standardized diagnostic protocols, making it easier to diagnose vehicles across different manufacturers. The CAN bus system, increasingly adopted in the 2000s, improved data communication within vehicles, enabling more comprehensive diagnostics. This evolution is detailed in a whitepaper by the Environmental Protection Agency (EPA), which emphasizes the role of OBD2 in emissions control and vehicle maintenance.

1.2 Key Differences Between OBD-I and OBD2

What are the main differences between OBD-I and OBD2 in terms of functionality and capabilities?

The key differences between OBD-I and OBD2 lie in standardization, diagnostic capabilities, and data accessibility. OBD-I systems were manufacturer-specific, meaning each carmaker used different diagnostic connectors, protocols, and trouble codes. This made diagnosing vehicles from different manufacturers challenging. OBD2, on the other hand, is standardized across all vehicles sold in the United States since 1996, featuring a universal diagnostic connector (SAE J1962) and a common set of diagnostic trouble codes (DTCs). OBD2 provides more comprehensive diagnostic information, including emissions-related data, live sensor readings, and freeze frame data, offering a more detailed view of the vehicle’s condition. According to research from the National Highway Traffic Safety Administration (NHTSA), OBD2 enhances vehicle safety by enabling quicker and more accurate identification of potential issues.

1.3 Understanding CAN Bus System

What is the CAN bus system, and how does it facilitate communication between vehicle components?

The CAN bus system is a robust communication network within a vehicle that allows various electronic control units (ECUs) to communicate with each other without relying on a central host computer. It operates using a two-wire system, transmitting data in a structured format that ensures reliability and speed. ECUs such as the engine control module (ECM), transmission control module (TCM), anti-lock braking system (ABS), and airbag control module can exchange information seamlessly. This enables coordinated control of vehicle systems and advanced diagnostic capabilities. A study by Robert Bosch GmbH highlights that the CAN bus system reduces wiring complexity, improves data accuracy, and supports advanced functions like electronic stability control and adaptive cruise control.

1.4 Advantages of Using CAN OBD2 Diagnostic Tools

What are the benefits of using digital CAN OBD2 diagnostic tools compared to older diagnostic methods?

Digital CAN OBD2 diagnostic tools offer numerous advantages over older diagnostic methods, including enhanced accuracy, speed, and versatility. These tools can quickly retrieve diagnostic trouble codes (DTCs), live sensor data, and freeze frame information, providing a comprehensive view of the vehicle’s health. They also support advanced functions like bidirectional control, allowing technicians to command certain vehicle components to activate for testing purposes. According to a report by the Automotive Service Association (ASA), the use of CAN OBD2 tools reduces diagnostic time by up to 50% compared to traditional methods. Furthermore, these tools are often equipped with extensive databases that provide detailed information about DTCs and repair procedures, streamlining the troubleshooting process.

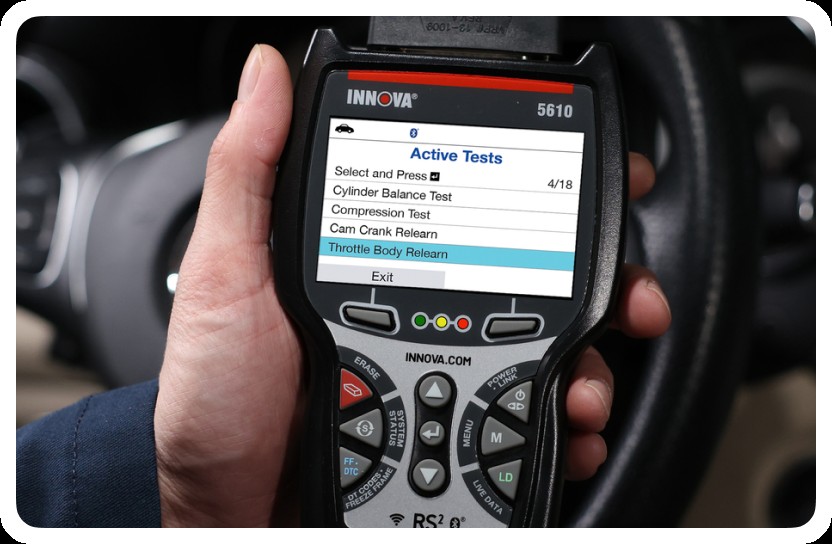

Digital CAN OBD2 diagnostic tool

Digital CAN OBD2 diagnostic tool

2. Selecting the Right OBD2 Diagnostic Tool

How do you choose the right OBD2 diagnostic tool for your specific needs and vehicle?

Selecting the right OBD2 diagnostic tool depends on your specific needs, technical expertise, and budget. For basic diagnostics, a simple code reader that retrieves and clears DTCs might suffice. For more advanced troubleshooting, consider a scan tool with features like live data streaming, bidirectional control, and access to manufacturer-specific codes. Professional mechanics may require high-end tools with advanced capabilities such as oscilloscope functions and vehicle programming. A comparison study by Consumer Reports recommends evaluating tools based on compatibility with your vehicle, ease of use, and the range of diagnostic functions offered.

2.1 Types of OBD2 Scanners Available

What are the different types of OBD2 scanners available in the market, and what are their typical features?

There are several types of OBD2 scanners available, each designed for different users and purposes. Basic code readers are simple, inexpensive devices that retrieve and clear diagnostic trouble codes (DTCs). Handheld scanners offer more advanced features such as live data streaming, freeze frame data, and enhanced code definitions. PC-based scanners connect to a laptop or desktop computer and provide comprehensive diagnostic capabilities, often with software updates and extensive databases. Professional-grade scanners are the most advanced, offering bidirectional control, oscilloscope functions, and manufacturer-specific diagnostics. According to a market analysis by Global Market Insights, the demand for advanced OBD2 scanners is increasing due to the growing complexity of modern vehicle systems.

2.2 Key Features to Look For in an OBD2 Scanner

What are the essential features to consider when purchasing an OBD2 scanner to ensure it meets your diagnostic needs?

When purchasing an OBD2 scanner, consider key features such as compatibility, functionality, and ease of use. Ensure the scanner supports all OBD2 protocols, including CAN, and is compatible with your vehicle’s make and model. Look for features like live data streaming, freeze frame data, and enhanced code definitions. Bidirectional control allows you to command certain vehicle components for testing. A user-friendly interface, clear display, and easy navigation are essential for efficient use. Consider scanners with software updates to ensure compatibility with newer vehicles and access to the latest diagnostic information. A review by Car and Driver emphasizes the importance of selecting a scanner with the features that align with your diagnostic skills and needs.

2.3 Compatibility with Different Vehicle Makes and Models

How can you ensure that an OBD2 scanner is compatible with your specific vehicle make and model?

Ensuring compatibility with your specific vehicle make and model is crucial when selecting an OBD2 scanner. Most scanners provide a compatibility list on their product page or packaging. Check this list to confirm that your vehicle is supported. Some scanners offer vehicle-specific software or updates that enhance compatibility and diagnostic capabilities. You can also consult the scanner manufacturer’s website or customer support for compatibility information. According to a guide by the National Institute for Automotive Service Excellence (ASE), using a scanner that is not fully compatible with your vehicle may result in inaccurate readings or incomplete diagnostic information.

2.4 Budget Considerations for OBD2 Diagnostic Tools

What is the typical price range for OBD2 diagnostic tools, and how do you balance cost with functionality?

The price range for OBD2 diagnostic tools varies widely, from around $20 for basic code readers to over $5,000 for professional-grade scanners. Basic code readers offer limited functionality, retrieving and clearing diagnostic trouble codes (DTCs). Mid-range handheld scanners, priced between $100 and $500, provide more advanced features like live data streaming and freeze frame data. Professional-grade scanners, which cost several thousand dollars, offer comprehensive diagnostic capabilities, including bidirectional control and manufacturer-specific diagnostics. When balancing cost with functionality, consider your diagnostic needs and skills. If you only need to read and clear codes occasionally, a basic code reader may suffice. For more in-depth troubleshooting, a mid-range scanner offers a good balance of features and affordability. Professional mechanics should invest in high-end scanners to meet the demands of their work. A study by Consumer Reports suggests reading user reviews and comparing features before making a purchase to ensure you get the best value for your money.

Different types of OBD2 scanners

Different types of OBD2 scanners

3. Step-by-Step Guide to Using a Digital CAN OBD2 Diagnostic Tool

What is the step-by-step process for using a digital CAN OBD2 diagnostic tool to diagnose vehicle issues?

The step-by-step process involves connecting the scanner to the vehicle’s OBD2 port, turning on the ignition, navigating the scanner’s menu to read diagnostic trouble codes (DTCs), interpreting the codes, and using the scanner to access live data for further analysis. The location of the OBD2 port is typically under the dashboard on the driver’s side. Once connected, the scanner will power on and display the vehicle’s information. Select the “Read Codes” option to retrieve any stored DTCs. Each code is associated with a specific fault in the vehicle’s system. After identifying the codes, you can use the scanner to access live data, such as sensor readings and engine parameters, to further diagnose the issue. According to a guide by the Automotive Technology Program at UCLA, understanding the diagnostic process and using the scanner’s features effectively can significantly reduce diagnostic time and improve accuracy.

3.1 Locating the OBD2 Port in Your Vehicle

Where is the OBD2 port typically located in a vehicle, and how do you identify it?

The OBD2 port is typically located under the dashboard on the driver’s side of the vehicle. It is a 16-pin connector that is trapezoidal in shape. In some vehicles, the port may be hidden behind a small panel or cover. Consult your vehicle’s owner’s manual if you have difficulty locating the port. The port is standardized across all vehicles sold in the United States since 1996, making it easy to identify. According to the Society of Automotive Engineers (SAE), the standardization of the OBD2 port simplifies the diagnostic process and ensures compatibility with all OBD2 scanners.

3.2 Connecting the OBD2 Scanner

How do you properly connect the OBD2 scanner to the vehicle’s OBD2 port?

To properly connect the OBD2 scanner, first locate the OBD2 port under the dashboard on the driver’s side. Ensure that the ignition is turned off. Align the scanner’s connector with the port and firmly push it in until it clicks into place. Some scanners may require you to turn on the ignition to power them up. Once connected, the scanner’s display should light up, indicating that it is receiving power. According to a guide by the National Institute for Automotive Service Excellence (ASE), a secure connection is essential for accurate data transmission.

3.3 Reading Diagnostic Trouble Codes (DTCs)

How do you use the OBD2 scanner to read diagnostic trouble codes (DTCs) stored in the vehicle’s computer?

To read diagnostic trouble codes (DTCs), turn the ignition to the “ON” position without starting the engine. Navigate the scanner’s menu to find the “Read Codes” or “Diagnostic Codes” option. Select this option, and the scanner will communicate with the vehicle’s computer to retrieve any stored DTCs. The codes will be displayed on the scanner’s screen, along with a brief description. Some scanners provide more detailed information about the codes, including possible causes and repair procedures. According to a report by the Automotive Service Association (ASA), understanding the meaning of DTCs is crucial for effective diagnostics.

3.4 Interpreting OBD2 Trouble Codes

How do you interpret the diagnostic trouble codes (DTCs) retrieved by the OBD2 scanner?

Interpreting OBD2 trouble codes involves understanding the standardized coding system used to identify specific faults in the vehicle’s system. DTCs are five-character codes that provide information about the location and nature of the problem. The first character indicates the system involved (e.g., P for powertrain, B for body, C for chassis, U for network). The second character indicates whether the code is generic (0) or manufacturer-specific (1). The third character indicates the specific subsystem (e.g., fuel system, ignition system). The last two characters indicate the specific fault. For example, P0300 indicates a random misfire detected in the powertrain system. Use the scanner’s built-in code definitions or consult a reliable online database to get a detailed explanation of each code. A guide by the Society of Automotive Engineers (SAE) provides a comprehensive list of OBD2 DTCs and their meanings.

3.5 Clearing Trouble Codes

When and how do you clear trouble codes using an OBD2 scanner?

Clearing trouble codes should be done after you have diagnosed and repaired the underlying issue that triggered the code. Clearing codes without addressing the problem will only result in the code reappearing. To clear codes, turn the ignition to the “ON” position without starting the engine. Navigate the scanner’s menu to find the “Erase Codes” or “Clear Codes” option. Select this option, and the scanner will prompt you to confirm the action. Confirm the action, and the scanner will clear the stored DTCs. After clearing the codes, start the engine and monitor the vehicle to ensure that the problem has been resolved and the codes do not reappear. According to a guide by the National Institute for Automotive Service Excellence (ASE), clearing codes should be part of a comprehensive diagnostic and repair process.

Interpreting OBD2 trouble codes

Interpreting OBD2 trouble codes

4. Advanced Features of Digital CAN OBD2 Diagnostic Tools

What advanced features are available in digital CAN OBD2 diagnostic tools, and how can they enhance your diagnostic capabilities?

Advanced digital CAN OBD2 diagnostic tools offer features such as live data streaming, freeze frame data, bidirectional control, and manufacturer-specific diagnostics. Live data streaming allows you to monitor real-time sensor readings and engine parameters, helping you identify intermittent problems and diagnose performance issues. Freeze frame data captures a snapshot of sensor readings at the moment a DTC was triggered, providing valuable information about the conditions that led to the fault. Bidirectional control allows you to command certain vehicle components to activate for testing purposes, such as turning on the cooling fan or activating the fuel pump. Manufacturer-specific diagnostics provide access to enhanced codes and diagnostic routines that are specific to certain vehicle makes and models. According to a market analysis by Global Market Insights, the increasing adoption of these advanced features is driving the growth of the OBD2 scanner market.

4.1 Live Data Streaming and Analysis

How do you use live data streaming to diagnose vehicle problems in real-time?

Live data streaming allows you to monitor real-time sensor readings and engine parameters as the vehicle is running, providing valuable insights into its performance. Connect the OBD2 scanner and navigate to the “Live Data” or “Data Stream” option. Select the parameters you want to monitor, such as engine RPM, coolant temperature, oxygen sensor readings, and fuel trim values. Start the engine and observe the data as it changes. Look for unusual patterns, deviations from normal values, or erratic readings that may indicate a problem. For example, a faulty oxygen sensor may show fluctuating voltage readings, while a malfunctioning mass airflow sensor may cause incorrect fuel trim values. Use this data to pinpoint the source of the problem and guide your diagnostic efforts. A guide by the Automotive Technology Program at UCLA emphasizes the importance of understanding normal operating ranges for various sensors and parameters to effectively interpret live data.

4.2 Freeze Frame Data

What is freeze frame data, and how can it help in diagnosing intermittent issues?

Freeze frame data is a snapshot of sensor readings and engine parameters that is captured at the moment a diagnostic trouble code (DTC) is triggered. This data provides valuable information about the conditions that led to the fault, such as engine speed, load, coolant temperature, and fuel trim values. Freeze frame data is particularly useful for diagnosing intermittent issues that may not be present when you connect the scanner. To access freeze frame data, navigate to the “Freeze Frame” or “Fault Data” option on the scanner. The scanner will display the stored data, allowing you to analyze the conditions that were present when the DTC was set. By comparing the freeze frame data with live data, you can gain a better understanding of the problem and identify the underlying cause. According to a report by the Automotive Service Association (ASA), freeze frame data can significantly reduce diagnostic time for intermittent issues.

4.3 Bidirectional Control

What is bidirectional control, and how can it be used to test vehicle components?

Bidirectional control is an advanced feature that allows you to command certain vehicle components to activate for testing purposes. This can be useful for verifying the functionality of components such as the cooling fan, fuel pump, injectors, and solenoids. To use bidirectional control, navigate to the “Bidirectional Control” or “Actuator Test” option on the scanner. Select the component you want to test, and follow the scanner’s instructions to activate it. Observe the component’s response to verify that it is functioning correctly. For example, you can use bidirectional control to turn on the cooling fan and check that it is operating at the correct speed. If the component does not respond as expected, it may indicate a fault that requires further investigation. A guide by the National Institute for Automotive Service Excellence (ASE) emphasizes the importance of following proper safety procedures when using bidirectional control.

4.4 Accessing Manufacturer-Specific Codes

How do you access manufacturer-specific codes using an OBD2 scanner, and why are they important?

Manufacturer-specific codes, also known as enhanced codes, are diagnostic trouble codes (DTCs) that are specific to certain vehicle makes and models. These codes provide more detailed information about the fault than generic OBD2 codes, helping you pinpoint the exact cause of the problem. To access manufacturer-specific codes, you need a scanner that supports enhanced diagnostics for your vehicle. Connect the scanner and navigate to the “Enhanced Codes” or “Manufacturer Codes” option. The scanner will communicate with the vehicle’s computer to retrieve any stored manufacturer-specific codes. These codes are often accompanied by more detailed descriptions and diagnostic procedures, making it easier to troubleshoot the issue. According to a report by Global Market Insights, the ability to access manufacturer-specific codes is a key factor driving the demand for advanced OBD2 scanners.

Live data streaming and analysis

Live data streaming and analysis

5. Common OBD2 Error Codes and Their Meanings

What are some common OBD2 error codes, and what do they indicate about potential vehicle problems?

Common OBD2 error codes include P0300 (random misfire detected), P0171 (system too lean), P0420 (catalyst system efficiency below threshold), P0301 (misfire detected in cylinder 1), and P0101 (mass airflow sensor circuit range/performance problem). P0300 indicates that the engine is experiencing random misfires, which can be caused by faulty spark plugs, ignition coils, or fuel injectors. P0171 indicates that the engine is running too lean, which can be caused by vacuum leaks, a faulty mass airflow sensor, or a clogged fuel filter. P0420 indicates that the catalytic converter is not functioning efficiently, which can lead to increased emissions. P0301 indicates that there is a misfire in cylinder 1, which can be caused by a faulty spark plug, ignition coil, or fuel injector in that cylinder. P0101 indicates that there is a problem with the mass airflow sensor circuit, which can affect the engine’s air-fuel mixture. A guide by the National Institute for Automotive Service Excellence (ASE) provides a comprehensive list of OBD2 error codes and their meanings.

5.1 P0300: Random Misfire Detected

What does the P0300 error code mean, and what are the potential causes and solutions?

The P0300 error code indicates that the engine is experiencing random misfires, meaning that one or more cylinders are not firing properly. This can result in rough idling, poor acceleration, and reduced fuel economy. Potential causes include faulty spark plugs, ignition coils, fuel injectors, vacuum leaks, low fuel pressure, and a faulty engine control module (ECM). To diagnose the problem, start by inspecting the spark plugs and ignition coils for signs of wear or damage. Check for vacuum leaks using a smoke machine or carburetor cleaner. Test the fuel injectors to ensure they are delivering the correct amount of fuel. If the problem persists, perform a compression test to check for cylinder problems. Solutions may include replacing faulty spark plugs, ignition coils, or fuel injectors, repairing vacuum leaks, cleaning or replacing the fuel filter, and replacing the ECM if necessary. According to a report by the Automotive Service Association (ASA), addressing misfires promptly can prevent further damage to the engine.

5.2 P0171: System Too Lean

What does the P0171 error code mean, and what are the common causes and fixes?

The P0171 error code indicates that the engine is running too lean, meaning that there is too much air and not enough fuel in the air-fuel mixture. This can result in poor performance, reduced fuel economy, and potential damage to the engine. Common causes include vacuum leaks, a faulty mass airflow sensor, a clogged fuel filter, low fuel pressure, faulty oxygen sensors, and a faulty fuel pump. To diagnose the problem, start by checking for vacuum leaks using a smoke machine or carburetor cleaner. Test the mass airflow sensor to ensure it is providing accurate readings. Check the fuel filter and fuel pressure to ensure the engine is receiving enough fuel. Inspect the oxygen sensors for signs of damage or contamination. Solutions may include repairing vacuum leaks, replacing the mass airflow sensor, cleaning or replacing the fuel filter, replacing the oxygen sensors, and replacing the fuel pump if necessary. A guide by the Society of Automotive Engineers (SAE) provides detailed diagnostic procedures for P0171 codes.

5.3 P0420: Catalyst System Efficiency Below Threshold

What does the P0420 error code signify, and how do you troubleshoot it effectively?

The P0420 error code indicates that the catalyst system efficiency is below the threshold, meaning that the catalytic converter is not functioning properly. The catalytic converter is responsible for reducing harmful emissions from the exhaust system. When it is not functioning efficiently, it can lead to increased emissions and potential damage to the engine. Common causes include a faulty catalytic converter, exhaust leaks, faulty oxygen sensors, and engine problems that are causing excessive emissions. To diagnose the problem, start by checking for exhaust leaks. Test the oxygen sensors to ensure they are providing accurate readings. Inspect the catalytic converter for signs of damage or deterioration. If the problem persists, the catalytic converter may need to be replaced. According to a report by the Environmental Protection Agency (EPA), maintaining a properly functioning catalytic converter is essential for reducing vehicle emissions and protecting the environment.

5.4 P0301: Cylinder 1 Misfire Detected

What does the P0301 error code indicate, and what steps should be taken to resolve it?

The P0301 error code indicates that there is a misfire detected in cylinder 1, meaning that the cylinder is not firing properly. This can result in rough idling, poor performance, and reduced fuel economy. Potential causes include a faulty spark plug, ignition coil, fuel injector, vacuum leak, low compression, and a faulty engine control module (ECM) in cylinder 1. To diagnose the problem, start by inspecting the spark plug and ignition coil for signs of wear or damage. Test the fuel injector to ensure it is delivering the correct amount of fuel. Check for vacuum leaks using a smoke machine or carburetor cleaner. Perform a compression test to check for cylinder problems. Solutions may include replacing the spark plug, ignition coil, or fuel injector in cylinder 1, repairing vacuum leaks, and replacing the ECM if necessary. A guide by the National Institute for Automotive Service Excellence (ASE) provides detailed diagnostic procedures for P0301 codes.

5.5 P0101: Mass Airflow Sensor Circuit Range/Performance Problem

What does the P0101 error code mean, and how do you address issues related to the mass airflow sensor?

The P0101 error code indicates that there is a problem with the mass airflow (MAF) sensor circuit range or performance, meaning that the sensor is not providing accurate readings to the engine control module (ECM). The MAF sensor measures the amount of air entering the engine, which is used to calculate the correct air-fuel mixture. Common causes include a dirty or faulty MAF sensor, vacuum leaks, a faulty air filter, wiring problems, and a faulty ECM. To diagnose the problem, start by inspecting the MAF sensor for signs of dirt or contamination. Clean the sensor using a MAF sensor cleaner. Check for vacuum leaks using a smoke machine or carburetor cleaner. Inspect the air filter to ensure it is clean and free of debris. Check the wiring and connectors for damage or corrosion. If the problem persists, the MAF sensor may need to be replaced. According to a report by the Automotive Service Association (ASA), maintaining a clean and properly functioning MAF sensor is essential for optimal engine performance.

Common OBD2 error codes

Common OBD2 error codes

6. Maintaining Your Vehicle Using OBD2 Diagnostics

How can you use OBD2 diagnostics to maintain your vehicle and prevent future problems?

OBD2 diagnostics can be used to monitor your vehicle’s performance, identify potential problems early, and perform preventative maintenance. Regularly scanning your vehicle for diagnostic trouble codes (DTCs) can help you detect issues before they become major problems. Use live data streaming to monitor sensor readings and engine parameters, identifying any deviations from normal values. Pay attention to maintenance reminders and perform recommended services on time. By using OBD2 diagnostics as part of your regular maintenance routine, you can keep your vehicle running smoothly and extend its lifespan. A guide by the National Institute for Automotive Service Excellence (ASE) provides detailed information on using OBD2 diagnostics for vehicle maintenance.

6.1 Regular OBD2 Scans for Preventative Maintenance

How often should you perform OBD2 scans for preventative maintenance, and what should you look for?

Performing regular OBD2 scans is a proactive way to maintain your vehicle and catch potential issues early. It is recommended to perform an OBD2 scan at least once a month, or more frequently if you notice any unusual symptoms such as rough idling, poor performance, or reduced fuel economy. When performing an OBD2 scan, look for any stored diagnostic trouble codes (DTCs), even if the check engine light is not illuminated. These pending codes can indicate developing problems that need to be addressed. Use live data streaming to monitor sensor readings and engine parameters, looking for any deviations from normal values. By regularly scanning your vehicle, you can identify potential problems early and take corrective action before they become major issues. A guide by the Automotive Technology Program at UCLA emphasizes the importance of regular OBD2 scans for preventative maintenance.

6.2 Monitoring Vehicle Performance with Live Data

How can you use live data to monitor your vehicle’s performance and identify potential issues?

Live data streaming allows you to monitor real-time sensor readings and engine parameters as the vehicle is running, providing valuable insights into its performance. Connect the OBD2 scanner and navigate to the “Live Data” or “Data Stream” option. Select the parameters you want to monitor, such as engine RPM, coolant temperature, oxygen sensor readings, and fuel trim values. Start the engine and observe the data as it changes. Look for unusual patterns, deviations from normal values, or erratic readings that may indicate a problem. For example, a faulty oxygen sensor may show fluctuating voltage readings, while a malfunctioning mass airflow sensor may cause incorrect fuel trim values. Use this data to identify potential issues and guide your diagnostic efforts. A guide by the National Institute for Automotive Service Excellence (ASE) provides detailed information on interpreting live data.

6.3 Addressing Potential Issues Early

Why is it important to address potential issues identified by OBD2 scans early, and what are the benefits?

Addressing potential issues identified by OBD2 scans early is crucial for preventing minor problems from escalating into major repairs. By addressing these issues promptly, you can avoid costly repairs, extend the lifespan of your vehicle, and improve its overall performance. Early detection and repair can also prevent further damage to other components, saving you time and money in the long run. Furthermore, addressing potential issues early can improve your vehicle’s fuel economy and reduce emissions, contributing to a cleaner environment. According to a report by the Environmental Protection Agency (EPA), regular maintenance and timely repairs can significantly reduce vehicle emissions and improve fuel efficiency.

6.4 Benefits of Regular Vehicle Maintenance

What are the overall benefits of performing regular vehicle maintenance using OBD2 diagnostics?

Performing regular vehicle maintenance using OBD2 diagnostics offers numerous benefits, including improved reliability, extended lifespan, enhanced performance, increased fuel economy, reduced emissions, and lower repair costs. Regular maintenance can help you identify and address potential problems early, preventing them from escalating into major repairs. It can also ensure that your vehicle is running at its optimal performance level, providing a smoother and more enjoyable driving experience. Furthermore, regular maintenance can improve your vehicle’s fuel economy and reduce emissions, saving you money and contributing to a cleaner environment. By using OBD2 diagnostics as part of your regular maintenance routine, you can keep your vehicle running smoothly and reliably for years to come. A guide by the National Institute for Automotive Service Excellence (ASE) emphasizes the importance of regular vehicle maintenance for ensuring vehicle safety and reliability.

7. Troubleshooting Common Issues with OBD2 Diagnostic Tools

What are some common issues that users may encounter with OBD2 diagnostic tools, and how can they be resolved?

Common issues with OBD2 diagnostic tools include connection problems, software glitches, compatibility issues, and inaccurate readings. Connection problems can be caused by a loose or damaged connector, a faulty OBD2 port, or a problem with the scanner’s cable. Software glitches can result in error messages, frozen screens, or incorrect data. Compatibility issues can occur if the scanner is not compatible with the vehicle’s make, model, or year. Inaccurate readings can be caused by faulty sensors, wiring problems, or a malfunctioning scanner. To troubleshoot these issues, start by checking the connection between the scanner and the vehicle. Ensure that the connector is securely plugged into the OBD2 port and that the cable is not damaged. Restart the scanner and update the software to the latest version. Check the scanner’s compatibility list to ensure that it supports your vehicle. If the problem persists, consult the scanner’s user manual or contact the manufacturer’s customer support for assistance. A guide by the Automotive Technology Program at UCLA provides detailed troubleshooting tips for OBD2 diagnostic tools.

7.1 Connection Problems

What are the common causes of connection problems with OBD2 scanners, and how can they be fixed?

Common causes of connection problems with OBD2 scanners include a loose or damaged connector, a faulty OBD2 port in the vehicle, a damaged scanner cable, and insufficient power supply to the scanner. To troubleshoot connection problems, start by inspecting the scanner connector and the OBD2 port for any signs of damage or corrosion. Ensure that the connector is securely plugged into the port. Check the scanner cable for any cuts, frays, or breaks. If the scanner is powered by the vehicle’s battery, check the battery voltage and ensure that it is sufficient to power the scanner. If the scanner is powered by an external power source, ensure that the power source is functioning correctly. If the problem persists, try using a different scanner or a different vehicle to isolate the issue. According to a guide by the National Institute for Automotive Service Excellence (ASE), a secure and reliable connection is essential for accurate data transmission.

7.2 Software Glitches

How can you troubleshoot software glitches in OBD2 diagnostic tools?

Software glitches in OBD2 diagnostic tools can manifest as error messages, frozen screens, incorrect data, or a failure to communicate with the vehicle’s computer. To troubleshoot software glitches, start by restarting the scanner. This can often resolve minor software issues. Check for software updates and install the latest version. Software updates often include bug fixes and performance improvements. Clear the scanner’s cache and data to remove any corrupted files. If the problem persists, try resetting the scanner to its factory settings. This will erase all user data and settings, so be sure to back up any important information before proceeding. If none of these steps resolve the issue, contact the scanner manufacturer’s customer support for assistance. A guide by the Automotive Technology Program at UCLA provides detailed troubleshooting tips for software glitches in OBD2 diagnostic tools.

7.3 Compatibility Issues

What should you do if your OBD2 scanner is not compatible with your vehicle?

If your OBD2 scanner is not compatible with your vehicle, there are several steps you can take to resolve the issue. First, check the scanner’s compatibility list to ensure that your vehicle’s make, model, and year are supported. Some scanners require specific software or adapters to work with certain vehicles. Ensure that you have the correct software and adapters installed. Update the scanner’s software to the latest version. Software updates often include compatibility improvements. Contact the scanner manufacturer’s customer support for assistance. They may be able to provide additional information or troubleshooting tips. If none of these steps resolve the issue, you may need to purchase a different scanner that is compatible with your vehicle. According to a guide by the Society of Automotive Engineers (SAE), using a scanner that is not fully compatible with your vehicle may result in inaccurate readings or incomplete diagnostic information.

7.4 Inaccurate Readings

What are the potential causes of inaccurate readings from an OBD2 scanner, and how can you ensure accurate results?

Potential causes of inaccurate readings from an OBD2 scanner include faulty sensors, wiring problems, a malfunctioning scanner, and incorrect data interpretation. To ensure accurate results, start by verifying that the scanner is properly connected to the vehicle and that the connection is secure. Check the scanner’s software to ensure that it is up to date. Inspect the vehicle’s sensors and wiring for any signs of damage or corrosion. Use a reliable source to interpret the diagnostic trouble codes (DTCs) and live data readings. Compare the readings with known good values to identify any discrepancies. If you suspect that the scanner is malfunctioning, try using a different scanner to verify the results. According to a guide by the National Institute for Automotive Service Excellence (ASE), accurate data is essential for effective diagnostics.

8. Advanced Diagnostic Techniques with OBD2 Scanners

What are some advanced diagnostic techniques that can be performed using OBD2 scanners, and how do they enhance your diagnostic capabilities?

Advanced diagnostic techniques with OBD2 scanners include performing relative compression tests, cylinder balance tests, and fuel injector tests. A relative compression test measures the cranking speed of each cylinder to identify cylinders with low compression. A cylinder balance test measures the contribution of each cylinder to the engine’s overall power output. A fuel injector test measures the fuel flow and spray pattern of each injector. These tests can help you pinpoint the source of engine problems and guide your diagnostic efforts. According to a guide by the Automotive Technology Program at UCLA, mastering these advanced techniques can significantly enhance your diagnostic capabilities.

8.1 Performing Relative Compression Tests

How do you perform a relative compression test using an OBD2 scanner, and what does it reveal?

A relative compression test is a diagnostic procedure used to assess the mechanical condition of an engine’s cylinders without physically removing the spark plugs and using a compression gauge. It measures the cranking speed of the engine as each cylinder comes up on its compression stroke. This test is performed using an OBD2 scanner that has the capability to monitor engine RPM and measure the voltage drop during cranking. To perform a relative compression test, disable the fuel injection system to prevent fuel from entering the cylinders during the test. Connect the OBD2 scanner to the vehicle and select the option to monitor engine RPM and voltage drop. Crank the engine and observe the readings. A cylinder with lower compression will cause the engine to crank faster, resulting in a lower voltage drop. By comparing the voltage drop for each cylinder, you can identify cylinders with low compression. This test can help diagnose problems such as worn piston rings, leaky valves, or cylinder head gasket failures. A guide by the National Institute for Automotive Service Excellence (ASE) provides detailed instructions on performing relative compression tests.

8.2 Conducting Cylinder Balance Tests

What is a cylinder balance test, and how can it help diagnose engine performance issues?

A cylinder balance test is a diagnostic procedure used to assess the contribution of each cylinder to the engine’s overall power output. This test can help identify cylinders that are not firing properly, which can result in rough idling, poor performance, and reduced fuel economy. To perform a cylinder balance test, connect the OBD2 scanner to the vehicle and select the option to perform a cylinder balance test. The scanner will temporarily disable each cylinder and measure the change in engine RPM. A cylinder that is not contributing its fair share of power will cause a greater drop in engine RPM when it is disabled. By comparing the RPM drop for each cylinder, you can identify cylinders that are not firing properly. This test can help diagnose problems such as faulty spark plugs, ignition coils, fuel injectors, or compression issues. A guide by the Automotive Technology Program at UCLA provides detailed information on conducting cylinder balance tests.