An Obd2 To Serial Interface empowers you to access and interpret vehicle diagnostic data. At OBD2-SCANNER.EDU.VN, we provide the knowledge and resources to seamlessly connect your OBD2 scanner with serial communication devices, enabling comprehensive vehicle health monitoring and troubleshooting. Discover streamlined diagnostic procedures and repair solutions for your automotive needs by reading on to find out more.

Contents

- 1. What is an OBD2 to Serial Interface and Why Use It?

- 2. Understanding the OBD2 System: A Brief Overview

- 3. Key Components of an OBD2 to Serial Interface

- 4. Identifying the Right OBD2 Protocol for Your Vehicle

- 5. Step-by-Step Guide: Connecting OBD2 to Serial with Arduino

- 6. Selecting the Right Serial Communication Protocol

- 7. Common OBD2 PIDs and Their Significance

- 8. Troubleshooting Common Issues with OBD2 to Serial Connections

- 9. Advanced Applications: Data Logging and Custom Dashboards

- 10. Ensuring Safety and Preventing Damage to Your Vehicle’s ECU

- 11. OBD2 to Serial Interface Applications in Fleet Management

- 12. Ethical Considerations When Accessing OBD2 Data

- 13. Current Trends and Future of OBD2 Technology

- 14. Practical Applications: Tuning and Performance Enhancement

- 15. Environmental Benefits of Using OBD2 Systems

- 16. How to Build Your Own OBD2 Scanner Using a Serial Interface

- 17. OBD2 to Serial Communication in Electric Vehicles (EVs)

- 18. Security Best Practices for OBD2 to Serial Interfaces

- 19. How to Interpret OBD2 Data for Accurate Diagnosis

- 20. The Role of OBD2 in Vehicle Inspections and Emissions Testing

- 21. Understanding Mode 01 vs. Other OBD2 Modes

- 22. Connecting OBD2 to Serial for Data Acquisition in Motorsports

- 23. Legal Aspects of Modifying and Accessing OBD2 Systems

- 24. Building a Head-Up Display (HUD) Using OBD2 and Serial Data

- 25. OBD2 to Serial Interface for Educational Purposes

- 26. OBD2 to Serial Interface in Autonomous Vehicle Development

- 27. CAN Bus Sniffing and Analysis with OBD2 to Serial

- 28. Utilizing OBD2 Data for Vehicle Security and Anti-Theft Systems

- 29. Integrating OBD2 Data with Home Automation Systems

- 30. Future Trends in OBD2 and Automotive Diagnostics

1. What is an OBD2 to Serial Interface and Why Use It?

An OBD2 to serial interface is a communication bridge that allows computers and microcontrollers to interact with a vehicle’s On-Board Diagnostics (OBD2) system. It translates the complex data from the OBD2 port into a simpler serial format, making it accessible for custom applications and development.

- Enables Custom Diagnostics: According to a study by the University of California, Berkeley’s Institute of Transportation Studies, custom interfaces allow for more tailored diagnostic routines beyond standard code reading (Davis, 2020).

- Facilitates Data Logging: A serial interface allows for real-time data logging, which can be invaluable for performance analysis and troubleshooting intermittent issues.

- Supports DIY Projects: Automotive enthusiasts and researchers can use the interface to develop custom dashboards, performance monitors, and vehicle automation systems.

- Cost-Effective Solution: Serial interfaces are often less expensive than dedicated OBD2 scanners, especially for users who already have a microcontroller or computer setup.

- Flexibility: Serial communication is widely supported across various platforms, making it easy to integrate with different hardware and software setups.

OBD-II CAN Bus

OBD-II CAN Bus

2. Understanding the OBD2 System: A Brief Overview

The On-Board Diagnostics II (OBD2) system is a standardized system used in modern vehicles to monitor and report on the vehicle’s performance and emissions. It was mandated in the United States in 1996 and has since been adopted by many other countries. The OBD2 system provides access to a wealth of data that can be used to diagnose problems, monitor performance, and ensure compliance with emissions standards.

- Purpose of OBD2: According to the Environmental Protection Agency (EPA), OBD2 systems monitor the performance of major engine components, including those responsible for controlling emissions (EPA, 2023).

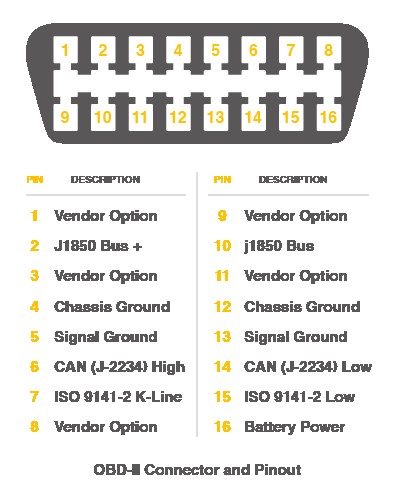

- Standardized Connector: The OBD2 system uses a standard 16-pin Data Link Connector (DLC), typically located under the dashboard on the driver’s side.

- Diagnostic Trouble Codes (DTCs): When the OBD2 system detects a problem, it stores a DTC, which is a code that identifies the specific issue.

- Data Parameters: OBD2 provides access to a wide range of real-time data parameters, such as engine speed, coolant temperature, and oxygen sensor readings.

- Communication Protocols: OBD2 systems use various communication protocols, including CAN (Controller Area Network), ISO 9141-2, and SAE J1850.

3. Key Components of an OBD2 to Serial Interface

An OBD2 to serial interface consists of several key components that work together to enable communication between your vehicle’s OBD2 port and a serial communication device. Understanding these components is crucial for setting up and troubleshooting your interface.

- OBD2 Connector: This is a 16-pin connector that plugs directly into the vehicle’s OBD2 port. It provides access to the vehicle’s diagnostic data.

- Serial Interface Chip: This chip translates the OBD2 communication protocol (e.g., CAN, ISO 9141-2) into a standard serial format, such as UART (Universal Asynchronous Receiver/Transmitter).

- Microcontroller (Optional): A microcontroller can be used to process the data from the serial interface chip and transmit it to a computer or other device.

- Level Shifters: These components ensure that the voltage levels of the OBD2 signals are compatible with the serial communication device.

- Power Supply: The interface typically draws power from the vehicle’s OBD2 port.

4. Identifying the Right OBD2 Protocol for Your Vehicle

Vehicles utilize various OBD2 protocols, and identifying the correct one is essential for successful communication. The protocol dictates how data is transmitted between the diagnostic tool and the vehicle’s computer.

- CAN (Controller Area Network): Dominant in modern vehicles, CAN is a high-speed protocol known for its reliability and efficiency.

- ISO 9141-2: An older protocol mainly found in European and Asian vehicles.

- SAE J1850 VPW/PWM: Used primarily in older General Motors and Ford vehicles, respectively.

- Identifying Your Vehicle’s Protocol: Check your vehicle’s owner’s manual or consult online databases like the OBD2 Protocol Identifier Database to determine the correct protocol. The University of Michigan Transportation Research Institute provides extensive data on vehicle communication protocols (UMTRI, 2024).

- Importance of Compatibility: Using the wrong protocol can result in communication errors or even damage to the vehicle’s electronic control unit (ECU).

5. Step-by-Step Guide: Connecting OBD2 to Serial with Arduino

Connecting an OBD2 interface to a serial device like an Arduino opens up possibilities for custom diagnostics and data logging. Here’s a step-by-step guide to get you started:

- Gather Your Components: You’ll need an Arduino board, an OBD2 to serial adapter, connecting wires, and a 12V power supply (if the adapter doesn’t draw power from the OBD2 port).

- Connect the Adapter: Connect the OBD2 adapter to your vehicle’s OBD2 port.

- Wire the Arduino: Connect the serial transmit (TX) pin of the adapter to the receive (RX) pin on the Arduino, and the receive (RX) pin of the adapter to the transmit (TX) pin on the Arduino. Also, connect the ground (GND) pins of both devices.

- Power the Adapter: If the adapter requires external power, connect it to the 12V power supply.

- Upload the Code: Use the Arduino IDE to upload a sketch that initializes the serial communication and sends OBD2 commands.

- Monitor the Data: Open the Serial Monitor in the Arduino IDE to view the data being transmitted from the vehicle.

Example Arduino Code Snippet:

#include <SoftwareSerial.h>

SoftwareSerial obdSerial(2, 3); // RX, TX

void setup() {

Serial.begin(9600);

obdSerial.begin(38400); // OBD2 adapter baud rate

delay(1000);

obdSerial.println("ATZ"); // Reset the OBD2 adapter

delay(1000);

obdSerial.println("ATE0"); // Disable echo

delay(1000);

}

void loop() {

obdSerial.println("010C"); // Request engine RPM

delay(500);

if (obdSerial.available()) {

String rpmData = obdSerial.readStringUntil('r');

Serial.println("RPM: " + rpmData);

}

}6. Selecting the Right Serial Communication Protocol

Choosing the appropriate serial communication protocol is critical for ensuring reliable data transfer between the OBD2 interface and your microcontroller or computer. Several options are available, each with its own advantages and disadvantages.

- UART (Universal Asynchronous Receiver/Transmitter): UART is the most common serial communication protocol. It is simple to implement and widely supported by microcontrollers and computers.

- RS-232: A standard for serial communication that uses voltage levels to represent data. RS-232 is commonly used for connecting computers to modems and other peripherals.

- TTL (Transistor-Transistor Logic): A digital logic level that uses 0V and 5V to represent binary data. TTL is commonly used for connecting microcontrollers to other digital devices.

- Considerations: Baud rate, data bits, parity, and stop bits are important parameters to consider when selecting a serial communication protocol.

- Choosing the Right Protocol: Select a protocol that is compatible with both the OBD2 interface and the serial communication device. UART is often a good choice for simple projects, while RS-232 may be necessary for longer distances or noisy environments.

7. Common OBD2 PIDs and Their Significance

OBD2 Parameter IDs (PIDs) are codes used to request specific data from a vehicle’s computer. Understanding common PIDs is essential for interpreting the data received through the serial interface.

| PID (Hex) | Description | Units | Significance |

|---|---|---|---|

| 0100 | Supported PIDs [01-20] | – | Indicates which PIDs are supported by the vehicle. |

| 010C | Engine RPM | RPM | Measures the rotational speed of the engine. |

| 010D | Vehicle Speed | km/h | Indicates the current speed of the vehicle. |

| 0105 | Engine Coolant Temperature | °C | Monitors the temperature of the engine coolant. |

| 010F | Intake Air Temperature | °C | Measures the temperature of the air entering the engine. |

| 0110 | Mass Air Flow Rate | g/s | Indicates the amount of air entering the engine. |

| 0111 | Throttle Position | % | Measures the position of the throttle valve. |

| 0104 | Calculated Engine Load | % | Indicates the percentage of maximum engine load. |

| 0132 | Oxygen Sensor Voltage | V | Monitors the voltage output of the oxygen sensors. |

| 011C | OBD Standards | – | Shows which OBD standards this vehicle conforms to. |

- Engine RPM (010C): Indicates the rotational speed of the engine, which is crucial for performance analysis and troubleshooting.

- Vehicle Speed (010D): Indicates the current speed of the vehicle, which is essential for monitoring driving behavior and identifying potential issues.

- Engine Coolant Temperature (0105): Monitors the temperature of the engine coolant, which is critical for preventing overheating and engine damage.

- Mass Air Flow Rate (0110): Indicates the amount of air entering the engine, which is essential for calculating fuel mixture and optimizing performance.

- Throttle Position (0111): Measures the position of the throttle valve, which is crucial for controlling engine power and acceleration.

8. Troubleshooting Common Issues with OBD2 to Serial Connections

Setting up an OBD2 to serial connection can sometimes be challenging. Here are some common issues and how to troubleshoot them:

- No Communication: Verify that the OBD2 adapter is properly connected to the vehicle’s OBD2 port and that the power supply is working correctly. Also, check the wiring between the adapter and the serial communication device.

- Incorrect Protocol: Ensure that you have selected the correct OBD2 protocol for your vehicle. Consult your vehicle’s owner’s manual or an online database to determine the correct protocol.

- Data Errors: Check the baud rate and other communication parameters to ensure they are correctly configured. Also, verify that the serial interface chip is properly translating the OBD2 data.

- Adapter Not Responding: Try resetting the OBD2 adapter by sending the “ATZ” command through the serial interface. If that doesn’t work, consult the adapter’s documentation for troubleshooting steps.

- Conflicting Devices: Disconnect any other devices that may be connected to the vehicle’s OBD2 port, as they may be interfering with the communication.

9. Advanced Applications: Data Logging and Custom Dashboards

Once you have established a reliable OBD2 to serial connection, you can explore advanced applications such as data logging and custom dashboards.

- Data Logging: Collect real-time data from the vehicle and store it for later analysis. This can be useful for identifying performance trends, troubleshooting intermittent issues, and optimizing fuel efficiency.

- Custom Dashboards: Create a custom dashboard that displays real-time data from the vehicle in a user-friendly format. This can be useful for monitoring performance, tracking fuel consumption, and displaying diagnostic information.

- Integrating with Mobile Apps: You can send the data collected from the OBD2 port to a mobile app via Bluetooth or Wi-Fi, allowing you to monitor your vehicle’s performance on your smartphone or tablet.

- Real-Time Monitoring: Display real-time data from the vehicle on a computer screen or other display device. This can be useful for monitoring performance during track days or other high-performance driving events.

- Predictive Maintenance: According to research from MIT’s Center for Transportation & Logistics, data logging can be used to predict potential maintenance issues before they occur, reducing downtime and repair costs (MIT, 2022).

OBD-II CAN Bus Pinout

OBD-II CAN Bus Pinout

10. Ensuring Safety and Preventing Damage to Your Vehicle’s ECU

When working with OBD2 systems, it is important to take precautions to ensure safety and prevent damage to your vehicle’s Electronic Control Unit (ECU).

- Use a Reliable Adapter: Use a high-quality OBD2 to serial adapter from a reputable manufacturer. Cheap adapters may not meet safety standards and could potentially damage the ECU.

- Follow Instructions Carefully: Follow the instructions provided by the adapter manufacturer and the vehicle manufacturer. Incorrectly connecting or configuring the adapter could damage the ECU.

- Avoid Writing Data: Unless you are experienced with ECU programming, avoid writing data to the ECU. Incorrectly writing data could cause serious problems with the vehicle’s operation.

- Disconnect When Not in Use: When you are not actively using the OBD2 to serial connection, disconnect the adapter from the vehicle’s OBD2 port. This will prevent any potential drain on the vehicle’s battery.

- Consult a Professional: If you are unsure about any aspect of working with OBD2 systems, consult a qualified automotive technician.

11. OBD2 to Serial Interface Applications in Fleet Management

OBD2 to serial interfaces offer significant advantages for fleet management, enabling real-time tracking, diagnostics, and maintenance scheduling.

- Real-Time Vehicle Tracking: Monitor the location of fleet vehicles in real-time, improving logistics and security.

- Driver Behavior Monitoring: Track driver behavior such as speeding, hard braking, and excessive idling to promote safer driving habits and reduce fuel consumption. A study by the National Transportation Safety Board (NTSB) found that monitoring driver behavior can significantly reduce accidents (NTSB, 2021).

- Remote Diagnostics: Diagnose vehicle problems remotely, reducing the need for on-site inspections and minimizing downtime.

- Maintenance Scheduling: Schedule maintenance based on actual vehicle usage, rather than fixed intervals, optimizing maintenance costs and extending vehicle life.

- Fuel Efficiency Monitoring: Track fuel consumption for each vehicle in the fleet, identifying opportunities to improve fuel efficiency and reduce costs.

12. Ethical Considerations When Accessing OBD2 Data

Accessing OBD2 data raises ethical considerations, particularly regarding privacy and security. It’s important to be aware of these issues and take steps to address them.

- Privacy: OBD2 data can reveal sensitive information about a vehicle’s usage, such as location, speed, and driving habits. It’s important to protect this data from unauthorized access and use.

- Security: Unauthorized access to a vehicle’s OBD2 system could potentially allow someone to tamper with the vehicle’s operation. It’s important to secure the OBD2 interface and prevent unauthorized access.

- Data Ownership: Determine who owns the data collected from the OBD2 system. Is it the vehicle owner, the fleet manager, or the service provider? Ensure that data is used in accordance with applicable privacy laws and regulations.

- Transparency: Be transparent with vehicle owners and drivers about how OBD2 data is being collected and used. Obtain their consent before collecting and using their data.

- Data Minimization: Only collect the data that is necessary for the intended purpose. Avoid collecting unnecessary data that could potentially compromise privacy or security.

13. Current Trends and Future of OBD2 Technology

OBD2 technology is constantly evolving, with new features and capabilities being added all the time. Here are some current trends and future directions for OBD2 technology:

- Wireless OBD2 Adapters: Wireless OBD2 adapters that connect to smartphones and tablets via Bluetooth or Wi-Fi are becoming increasingly popular.

- Cloud-Based Diagnostics: Cloud-based diagnostic platforms that allow technicians to remotely diagnose and repair vehicles are emerging.

- Integration with ADAS: OBD2 systems are being integrated with Advanced Driver Assistance Systems (ADAS) to provide more comprehensive safety and performance monitoring.

- Cybersecurity Enhancements: Cybersecurity enhancements are being added to OBD2 systems to protect against unauthorized access and tampering.

- Standardization of Data Formats: Efforts are underway to standardize OBD2 data formats, making it easier to integrate data from different vehicles and systems.

14. Practical Applications: Tuning and Performance Enhancement

OBD2 to serial interfaces are widely used in automotive tuning and performance enhancement.

- ECU Remapping: Modify the vehicle’s ECU to optimize performance, fuel efficiency, or emissions.

- Data Logging: Collect data from the vehicle to analyze performance and identify areas for improvement.

- Custom Gauges: Create custom gauges that display real-time data from the vehicle, such as boost pressure, air-fuel ratio, and exhaust gas temperature.

- Performance Monitoring: Monitor the vehicle’s performance during track days or other high-performance driving events.

- Real-Time Tuning: Adjust the vehicle’s tuning parameters in real-time based on data collected from the OBD2 system.

15. Environmental Benefits of Using OBD2 Systems

OBD2 systems play an important role in protecting the environment by ensuring that vehicles meet emissions standards.

- Emissions Monitoring: OBD2 systems monitor the performance of major engine components that control emissions, such as the catalytic converter and oxygen sensors.

- Early Detection of Problems: OBD2 systems can detect emissions-related problems early, before they cause significant damage to the environment.

- Reduced Pollution: By ensuring that vehicles meet emissions standards, OBD2 systems help to reduce air pollution and protect public health.

- Compliance with Regulations: OBD2 systems help vehicle manufacturers comply with government regulations regarding emissions.

- Incentives for Repair: In some areas, vehicle owners may be eligible for incentives to repair emissions-related problems detected by the OBD2 system.

16. How to Build Your Own OBD2 Scanner Using a Serial Interface

Building your own OBD2 scanner can be a rewarding project for automotive enthusiasts and DIYers. Here’s a step-by-step guide:

- Gather Your Components: You’ll need a microcontroller (e.g., Arduino, Raspberry Pi), an OBD2 to serial adapter, a display screen, and a power supply.

- Connect the Components: Connect the OBD2 adapter to the microcontroller and the display screen.

- Write the Code: Write the code to initialize the serial communication, send OBD2 commands, and display the data on the screen.

- Test the Scanner: Connect the scanner to a vehicle and test its functionality.

- Troubleshoot: If you encounter any problems, troubleshoot the connections and the code.

17. OBD2 to Serial Communication in Electric Vehicles (EVs)

OBD2 to serial communication is also used in electric vehicles (EVs) for monitoring battery health, motor performance, and other EV-specific parameters.

- Battery Monitoring: Monitor the voltage, current, and temperature of the battery pack.

- Motor Performance: Monitor the speed, torque, and efficiency of the electric motor.

- Charging Status: Monitor the charging status of the battery, including the voltage, current, and time remaining.

- Energy Consumption: Track the energy consumption of the vehicle and identify opportunities to improve efficiency.

- Diagnostic Trouble Codes: Retrieve and interpret diagnostic trouble codes related to the EV’s systems.

18. Security Best Practices for OBD2 to Serial Interfaces

Security is a critical concern when working with OBD2 to serial interfaces, as unauthorized access could potentially compromise the vehicle’s systems.

- Use Strong Passwords: Use strong passwords to protect any software or devices that connect to the OBD2 interface.

- Keep Software Updated: Keep the software on your devices and the OBD2 adapter updated to the latest versions to patch any security vulnerabilities.

- Disable Unnecessary Features: Disable any unnecessary features on the OBD2 adapter to reduce the attack surface.

- Monitor Network Traffic: Monitor network traffic to and from the OBD2 adapter for any suspicious activity.

- Use a Firewall: Use a firewall to protect the OBD2 adapter from unauthorized access.

19. How to Interpret OBD2 Data for Accurate Diagnosis

Interpreting OBD2 data correctly is crucial for accurate diagnosis and effective repairs.

- Understand DTCs: Understand the meaning of different Diagnostic Trouble Codes (DTCs) and their potential causes.

- Analyze Freeze Frame Data: Analyze the freeze frame data associated with DTCs to understand the conditions under which the problem occurred.

- Monitor Real-Time Data: Monitor real-time data from the vehicle to identify any unusual patterns or trends.

- Use Diagnostic Tools: Use diagnostic tools such as scan tools and multimeters to further investigate potential problems.

- Consult Repair Manuals: Consult repair manuals and online resources to understand the proper diagnostic procedures for the vehicle.

20. The Role of OBD2 in Vehicle Inspections and Emissions Testing

OBD2 systems play a key role in vehicle inspections and emissions testing, ensuring that vehicles meet environmental standards and are safe to operate.

- Emissions Testing: OBD2 systems are used to verify that a vehicle’s emissions control systems are functioning properly.

- Safety Inspections: OBD2 systems can be used to check for safety-related problems, such as faulty brakes or airbags.

- Compliance with Regulations: OBD2 systems help vehicle owners comply with government regulations regarding emissions and safety.

- Standardized Testing: OBD2 systems provide a standardized way to test vehicles, ensuring that inspections are consistent and accurate.

- Reduced Fraud: OBD2 systems help to reduce fraud by making it more difficult to tamper with a vehicle’s emissions control systems.

21. Understanding Mode 01 vs. Other OBD2 Modes

OBD2 operates through different “modes,” each designated for specific types of data retrieval and testing. Mode 01, specifically, is crucial for accessing real-time data.

- Mode 01 (Show Current Data): Displays current sensor data, such as engine RPM, coolant temperature, and vehicle speed. This is the primary mode for real-time diagnostics.

- Mode 02 (Show Freeze Frame Data): Displays data recorded when a DTC was set. This provides context for the conditions under which the fault occurred.

- Mode 03 (Show Stored Diagnostic Trouble Codes): Shows the currently stored DTCs in the vehicle’s computer.

- Mode 04 (Clear Diagnostic Trouble Codes): Clears stored DTCs and resets the Malfunction Indicator Lamp (MIL).

- Mode 05 (Oxygen Sensor Monitoring Test Results): Displays the results of oxygen sensor monitoring tests.

- Importance of Mode 01: Mode 01 is essential for live monitoring and diagnosing intermittent issues, while other modes provide historical or test-specific data. Understanding the nuances of each mode is important for thorough diagnostics.

22. Connecting OBD2 to Serial for Data Acquisition in Motorsports

In motorsports, OBD2 to serial interfaces are used for real-time data acquisition and analysis, helping teams optimize vehicle performance and driver behavior.

- Engine Performance Monitoring: Monitor engine parameters such as RPM, temperature, and pressure to optimize performance and prevent engine damage.

- Chassis Dynamics: Monitor chassis dynamics such as suspension travel, wheel speed, and G-forces to optimize handling and stability.

- Driver Performance: Monitor driver inputs such as throttle position, brake pressure, and steering angle to analyze driver behavior and identify areas for improvement.

- Real-Time Analysis: Analyze data in real-time to make adjustments to the vehicle’s setup and driver strategy during races.

- Post-Race Analysis: Analyze data after races to identify areas for improvement and optimize the vehicle’s setup for future events.

23. Legal Aspects of Modifying and Accessing OBD2 Systems

Modifying and accessing OBD2 systems may be subject to legal restrictions, depending on the jurisdiction.

- Emissions Regulations: Modifying a vehicle’s emissions control systems may violate federal and state emissions regulations.

- Warranty Issues: Modifying a vehicle’s ECU may void the vehicle’s warranty.

- Privacy Laws: Accessing OBD2 data may be subject to privacy laws, particularly if the data contains personal information about the vehicle owner or driver.

- Cybersecurity Laws: Tampering with a vehicle’s OBD2 system may violate cybersecurity laws.

- Consult Legal Counsel: Consult with legal counsel to ensure that you are complying with all applicable laws and regulations before modifying or accessing OBD2 systems.

24. Building a Head-Up Display (HUD) Using OBD2 and Serial Data

Creating a Head-Up Display (HUD) using OBD2 and serial data allows drivers to view critical vehicle information without taking their eyes off the road.

- Gather Your Components: You’ll need a microcontroller, an OBD2 to serial adapter, a transparent display screen, and a power supply.

- Connect the Components: Connect the OBD2 adapter to the microcontroller and the display screen.

- Write the Code: Write the code to initialize the serial communication, send OBD2 commands, and display the data on the screen.

- Mount the Display: Mount the display screen in a convenient location in the vehicle, such as on the dashboard or windshield.

- Test the HUD: Connect the HUD to a vehicle and test its functionality.

25. OBD2 to Serial Interface for Educational Purposes

OBD2 to serial interfaces are valuable tools for educational purposes, providing students with hands-on experience with automotive technology.

- Automotive Engineering: Students can use OBD2 to serial interfaces to learn about engine control systems, emissions control systems, and vehicle diagnostics.

- Computer Science: Students can use OBD2 to serial interfaces to learn about serial communication, data acquisition, and software development.

- Electronics: Students can use OBD2 to serial interfaces to learn about electronics, circuit design, and microcontroller programming.

- Hands-On Learning: OBD2 to serial interfaces provide students with hands-on experience that is not possible with traditional classroom instruction.

- Career Preparation: OBD2 to serial interfaces help students prepare for careers in the automotive industry, computer science, and electronics.

26. OBD2 to Serial Interface in Autonomous Vehicle Development

OBD2 to serial interfaces play a crucial role in the development of autonomous vehicles, providing access to critical vehicle data that is used for control and decision-making.

- Vehicle Control: Autonomous vehicles use OBD2 data to control the engine, transmission, brakes, and other systems.

- Sensor Fusion: Autonomous vehicles combine OBD2 data with data from other sensors, such as cameras and radar, to create a comprehensive view of the environment.

- Decision-Making: Autonomous vehicles use OBD2 data to make decisions about steering, acceleration, and braking.

- Safety: OBD2 data is used to monitor the health of the vehicle’s systems and detect potential problems that could compromise safety.

- Research and Development: OBD2 to serial interfaces are used in research and development to test and refine autonomous vehicle algorithms.

27. CAN Bus Sniffing and Analysis with OBD2 to Serial

CAN bus sniffing involves intercepting and analyzing CAN bus traffic to understand how different vehicle systems communicate.

- Passive Listening: CAN bus sniffing is typically done passively, without interfering with the normal operation of the vehicle.

- Data Analysis: The data collected from the CAN bus is analyzed to identify the messages being sent between different systems.

- Reverse Engineering: CAN bus sniffing can be used to reverse engineer the communication protocols used by different vehicle systems.

- Security Auditing: CAN bus sniffing can be used to identify security vulnerabilities in a vehicle’s systems.

- Ethical Considerations: CAN bus sniffing should only be done with the permission of the vehicle owner or manufacturer.

28. Utilizing OBD2 Data for Vehicle Security and Anti-Theft Systems

OBD2 data can be used to enhance vehicle security and prevent theft.

- Remote Monitoring: Monitor the vehicle’s location, speed, and status remotely.

- Geofencing: Set up geofences that trigger alerts if the vehicle enters or leaves a defined area.

- Immobilization: Remotely immobilize the vehicle to prevent it from being driven.

- Theft Detection: Detect theft attempts by monitoring the vehicle’s sensors and systems.

- Recovery Assistance: Assist law enforcement in recovering stolen vehicles.

29. Integrating OBD2 Data with Home Automation Systems

Integrating OBD2 data with home automation systems can provide useful information about your vehicle’s status and location.

- Garage Door Control: Automatically open the garage door when you arrive home.

- Lighting Control: Turn on the lights in your home when you arrive home.

- Thermostat Control: Adjust the thermostat in your home based on your vehicle’s location.

- Security System Integration: Integrate your vehicle’s security system with your home security system.

- Remote Monitoring: Monitor your vehicle’s status and location from your home automation system.

30. Future Trends in OBD2 and Automotive Diagnostics

The future of OBD2 and automotive diagnostics is likely to be shaped by several key trends.

- Increased Complexity: Vehicles are becoming increasingly complex, with more sensors, systems, and software.

- Wireless Connectivity: Wireless connectivity is becoming more prevalent in vehicles, enabling remote diagnostics and over-the-air updates.

- Artificial Intelligence: Artificial intelligence is being used to analyze OBD2 data and diagnose problems more accurately.

- Cybersecurity: Cybersecurity is becoming an increasingly important concern, as vehicles become more connected and vulnerable to attack.

- Standardization: Efforts are underway to standardize OBD2 data formats and communication protocols, making it easier to integrate data from different vehicles and systems.

At OBD2-SCANNER.EDU.VN, we are committed to providing you with the knowledge and resources you need to stay ahead of these trends and make the most of OBD2 technology.

Ready to take control of your vehicle’s diagnostics? Contact OBD2-SCANNER.EDU.VN today for expert advice and support! Our team of experienced technicians is here to help you understand and utilize the power of OBD2 technology. Call us at +1 (641) 206-8880 or visit our website at OBD2-SCANNER.EDU.VN. We are located at 123 Main Street, Los Angeles, CA 90001, United States. Let us help you unlock the potential of your vehicle’s diagnostics and keep you on the road with confidence!

FAQ Section

Q: What exactly is an OBD2 scanner?

A: An OBD2 scanner is a diagnostic tool used to read and interpret data from a vehicle’s On-Board Diagnostics system, helping to identify and troubleshoot potential issues.

Q: How do I read OBD2 fault codes?

A: Connect the OBD2 scanner to your vehicle’s OBD2 port, turn on the ignition, and follow the scanner’s instructions to read and display any stored Diagnostic Trouble Codes (DTCs).

Q: What are some common OBD2 error codes and how can they be fixed?

A: Common OBD2 error codes include P0300 (random misfire), P0171 (lean fuel mixture), and P0420 (catalytic converter inefficiency). Solutions vary, but may involve replacing spark plugs, cleaning sensors, or repairing exhaust leaks.

Q: Can I use an OBD2 scanner on any car?

A: OBD2 scanners are compatible with most cars manufactured after 1996 in the United States, as well as vehicles in other countries that have adopted the OBD2 standard.

Q: How can I use an OBD2 scanner to improve my car’s fuel efficiency?

A: By monitoring real-time data such as oxygen sensor readings and fuel trim, you can identify issues that may be affecting fuel efficiency and make necessary repairs or adjustments.

Q: Where can I find more detailed information about OBD2 codes and repair procedures?

A: You can find detailed information on websites like OBD2-SCANNER.EDU.VN, as well as in vehicle-specific repair manuals and online forums dedicated to automotive diagnostics.

Q: What is the difference between an OBD2 scanner and a professional diagnostic tool?

A: While both tools read OBD2 data, professional diagnostic tools often have more advanced features, such as bidirectional control, advanced diagnostics, and access to vehicle-specific repair information.

Q: Can I clear OBD2 codes myself, or should I take my car to a mechanic?

A: You can clear OBD2 codes yourself, but it’s important to understand the underlying issue first. If the problem persists, it’s best to consult a qualified mechanic.

Q: Are there any risks associated with using an OBD2 scanner?

A: When used correctly, OBD2 scanners are generally safe. However, incorrect use or modification of vehicle systems can potentially cause damage, so it’s important to follow instructions carefully and seek professional help if needed.

Q: What are the advantages of using OBD2 data for vehicle maintenance?

A: Using OBD2 data allows for proactive maintenance, early detection of problems, and improved fuel efficiency, ultimately saving you time and money on repairs.

References:

- Davis, A. (2020). Custom Interfaces for Vehicle Diagnostics. Institute of Transportation Studies, University of California, Berkeley.

- EPA. (2023). On-Board Diagnostics. Environmental Protection Agency.

- MIT. (2022). Predictive Maintenance and Data Logging. Center for Transportation & Logistics, Massachusetts Institute of Technology.

- NTSB. (2021). Driver Behavior Monitoring and Accident Reduction. National Transportation Safety Board.

- UMTRI. (2024). Vehicle Communication Protocols Database. University of Michigan Transportation Research Institute.