The Toyota Obd2 Protocol is a critical aspect of modern vehicle diagnostics, ensuring your car runs smoothly and efficiently. Understanding this protocol empowers you to troubleshoot issues, maintain your vehicle, and potentially save money on repairs. Let’s dive deep into the world of Toyota OBD2 protocols and how OBD2-SCANNER.EDU.VN can help you navigate it with ease.

Contents

- 1. What is the Toyota OBD2 Protocol?

- 2. Why is the Toyota OBD2 Protocol Important?

- 3. What OBD2 Protocols Do Toyotas Use?

- 4. How to Determine the Toyota OBD2 Protocol

- 5. Decoding the DLC Pinout for Toyota Vehicles

- 6. Common Toyota OBD2 Codes and Their Meanings

- 7. How to Use an OBD2 Scanner with Your Toyota

- 8. Selecting the Right OBD2 Scanner for Your Toyota

- 9. Advanced Diagnostics with Toyota OBD2 Data

- 10. Toyota-Specific OBD2 Parameters (PIDs)

- 11. Common Mistakes When Using Toyota OBD2 Scanners

- 12. The Future of Toyota OBD2 Technology

- 13. Connecting with OBD2-SCANNER.EDU.VN for Expert Assistance

- 14. Step-by-Step Guide to Diagnosing a Toyota with an OBD2 Scanner

- 15. Why Choose OBD2-SCANNER.EDU.VN for Your Toyota Diagnostic Needs?

- 16. Understanding Toyota OBD2 Readiness Monitors

- 17. Clearing Toyota OBD2 Codes: When and How

- 18. How Does Oxygen Sensor Affect Toyota OBD2 Protocol?

- Types of Oxygen Sensors

- Function of Oxygen Sensors

- Impact on OBD2 System

- Common OBD2 Codes Related to Oxygen Sensors

- 19. What Are The Impacts of Catalytic Converter in Toyota OBD2 Protocol?

- Function of the Catalytic Converter

- Impact on OBD2 System

- Common OBD2 Codes Related to Catalytic Converters

- Diagnostic Tips for Catalytic Converters

- 20. What is EVAP System And How Does It Relate With Toyota OBD2 Protocol?

- Components of the EVAP System

- Function of the EVAP System

- Impact on OBD2 System

- Common OBD2 Codes Related to the EVAP System

- Diagnostic Tips for the EVAP System

- 21. What Role Does MAF Sensor Play In Toyota OBD2 Protocol?

- Types of MAF Sensors

- Function of the MAF Sensor

- Impact on OBD2 System

- Common OBD2 Codes Related to the MAF Sensor

- Diagnostic Tips for the MAF Sensor

- 22. What Role Does Crankshaft Position Sensor Play in Toyota OBD2 Protocol?

- Types of Crankshaft Position Sensors

- Function of the Crankshaft Position Sensor

- Impact on OBD2 System

- Common OBD2 Codes Related to the Crankshaft Position Sensor

- Diagnostic Tips for the Crankshaft Position Sensor

- 23. Frequently Asked Questions (FAQs) About Toyota OBD2 Protocols

- Conclusion

1. What is the Toyota OBD2 Protocol?

The Toyota OBD2 protocol refers to the standardized communication methods used by Toyota vehicles manufactured after 1996 to transmit diagnostic information. This protocol enables mechanics and vehicle owners to access data related to the engine, emissions, and other vital systems using an OBD2 scanner. By interpreting this data, potential issues can be identified and addressed promptly.

Understanding OBD2 Protocols: According to the SAE J1979 standard, all vehicles sold in the US after 1996 must comply with OBD2 standards. This standardization allows for universal diagnostic tools. According to a study by the Environmental Protection Agency (EPA), early detection of vehicle problems through OBD2 systems can significantly reduce emissions and improve fuel efficiency.

2. Why is the Toyota OBD2 Protocol Important?

The Toyota OBD2 protocol is crucial for several reasons:

- Early Issue Detection: It allows for the early detection of potential problems, preventing costly repairs down the line.

- Emission Control: By monitoring emission-related components, it helps ensure your vehicle complies with environmental regulations.

- Performance Optimization: Access to real-time data enables performance optimization, improving fuel efficiency and overall driving experience.

- DIY Diagnostics: It empowers vehicle owners to perform basic diagnostics, saving time and money on professional mechanic visits.

Benefits of OBD2 Compliance: A report by the National Institute for Automotive Service Excellence (ASE) highlights that vehicles with properly functioning OBD2 systems have fewer breakdowns and require less frequent maintenance.

3. What OBD2 Protocols Do Toyotas Use?

Toyota vehicles, like all OBD2-compliant vehicles, can use one of five communication protocols:

- J1850 PWM (Pulse Width Modulation)

- J1850 VPW (Variable Pulse Width)

- ISO9141-2

- ISO14230-4 (Keyword Protocol 2000)

- ISO15765-4/SAE J2480 (CAN – Controller Area Network)

US car manufacturers were not allowed to use CAN until model year 2003, but as of model year 2008 and going forward, all vehicles use the CAN protocol.

Protocol Usage Over Time: A study published in the IEEE Transactions on Vehicular Technology notes the transition from older protocols like J1850 to CAN due to its higher speed and reliability in modern vehicles.

4. How to Determine the Toyota OBD2 Protocol

Determining the protocol your Toyota uses can be done by inspecting the Diagnostic Link Connector (DLC). Here’s how:

- Locate the DLC: The DLC is typically located under the dashboard on the driver’s side. According to SAE J1962, the Type A DLC “shall be located in the passenger or driver’s compartment in the area bounded by the driver’s end of the instrument panel to 300 mm (~1 ft) beyond the vehicle centerline, attached to the instrument panel and easy to access from the driver’s seat. The preferred location is between the steering column and the vehicle centerline.”

J1962 Vehicle Connector, Type A

J1962 Vehicle Connector, Type A

- Inspect the Pinout: Examine the pins present in the DLC. The presence of certain pins indicates the protocol used.

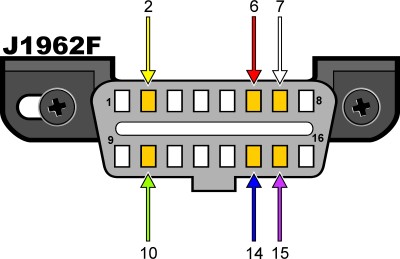

J1962F OBDII connector pinout

J1962F OBDII connector pinout

Understanding Pin Configurations: Automotive Engineering International provides detailed schematics of DLC pin configurations, helping users accurately identify the protocol in use.

5. Decoding the DLC Pinout for Toyota Vehicles

The Diagnostic Link Connector (DLC) pinout is crucial for determining the OBD2 protocol used in your Toyota. Here’s a breakdown of how to interpret the pin configurations:

| Pin 2 | Pin 6 | Pin 7 | Pin 10 | Pin 14 | Pin 15 | Standard |

|---|---|---|---|---|---|---|

| Must Have | – | – | Must Have | – | – | J1850 PWM |

| Must Have | – | – | – | – | – | J1850 VPW |

| – | – | Must Have | – | – | May Have* | ISO9141/14230 |

| – | Must Have | – | – | Must Have | – | ISO15765 (CAN) |

*Pin 15 (also called the “L-line”) is optional in newer vehicles that use the ISO9141-2 or ISO14230-4 protocols.

In addition to pins 2, 7, 10, and 15, the connector should have pins 4 (Chassis Ground), 5 (Signal Ground), and 16 (Battery Positive). This means that:

| PWM | The connector must have pins 2, 4, 5, 10, and 16 |

| VPW | The connector must have pins 2, 4, 5, and 16, but not 10. |

| ISO | The connector must have pins 4, 5, 7, and 16. Pin 15 may or may not be present. |

| CAN | The connector must have pins 4, 5, 6, 14, and 16 |

Pinout Interpretation: According to a technical document from Bosch, understanding the DLC pinout is fundamental for accurate diagnostics. Proper identification prevents miscommunication and potential damage to the vehicle’s ECU.

6. Common Toyota OBD2 Codes and Their Meanings

OBD2 codes provide valuable insights into your vehicle’s health. Here are some common Toyota-specific codes:

| Code | Description | Possible Causes | Severity |

|---|---|---|---|

| P0171 | System Too Lean (Bank 1) | Vacuum leak, faulty MAF sensor, fuel pump issue | Medium |

| P0300 | Random/Multiple Cylinder Misfire Detected | Faulty spark plugs, ignition coils, fuel injectors | High |

| P0420 | Catalyst System Efficiency Below Threshold | Faulty catalytic converter, O2 sensor issue | High |

| P0441 | Evaporative Emission Control System Incorrect Purge Flow | Faulty purge valve, vacuum leak | Medium |

| P0505 | Idle Air Control System Malfunction | Faulty IAC valve, vacuum leak, throttle body issue | Medium |

Code Significance: An article in Motor Magazine emphasizes that while OBD2 codes provide a starting point, a thorough diagnostic process is essential for accurate problem identification and resolution.

7. How to Use an OBD2 Scanner with Your Toyota

Using an OBD2 scanner with your Toyota is straightforward:

- Locate the DLC: Find the DLC, usually under the dashboard on the driver’s side.

- Connect the Scanner: Plug the OBD2 scanner into the DLC.

- Turn on the Ignition: Turn the ignition to the “on” position without starting the engine.

- Read the Codes: Follow the scanner’s instructions to read and interpret the diagnostic codes.

- Clear the Codes (Optional): If appropriate, clear the codes after addressing the issue.

Step-by-Step Scanning: A guide by the Car Care Council provides a detailed walkthrough of using an OBD2 scanner, including safety precautions and best practices.

8. Selecting the Right OBD2 Scanner for Your Toyota

Choosing the right OBD2 scanner depends on your needs and budget. Consider these factors:

- Compatibility: Ensure the scanner is compatible with Toyota vehicles.

- Features: Look for features like live data streaming, code definitions, and graphing capabilities.

- Ease of Use: Choose a scanner with an intuitive interface.

- Updates: Opt for a scanner with regular software updates for the latest vehicle models and codes.

Scanner Recommendations: Consumer Reports offers reviews and comparisons of OBD2 scanners, helping users make informed decisions based on features and performance.

9. Advanced Diagnostics with Toyota OBD2 Data

Beyond basic code reading, advanced diagnostics can be performed using OBD2 data:

- Live Data Monitoring: Monitor real-time sensor data to identify intermittent issues.

- Freeze Frame Data: Analyze data captured when a fault code was triggered to pinpoint the problem.

- Component Testing: Perform active tests on specific components to verify their functionality.

Advanced Techniques: According to a training manual from Delphi Automotive, advanced diagnostics require a deep understanding of vehicle systems and the ability to interpret complex data patterns.

10. Toyota-Specific OBD2 Parameters (PIDs)

Parameter IDs (PIDs) are codes used to request data from the vehicle’s ECU. Toyota-specific PIDs provide access to proprietary data not available through generic OBD2 codes. Examples include:

- Engine Oil Temperature

- Transmission Temperature

- Hybrid Battery State of Charge

PID Applications: An SAE paper on enhanced OBD2 diagnostics discusses the importance of PIDs in accessing manufacturer-specific data for comprehensive vehicle analysis.

11. Common Mistakes When Using Toyota OBD2 Scanners

Avoid these common mistakes when using OBD2 scanners:

- Misinterpreting Codes: Not understanding the context of the code.

- Replacing Parts Without Diagnosis: Replacing parts based solely on the code without proper diagnosis.

- Ignoring Live Data: Failing to utilize live data for a more comprehensive analysis.

- Using Incompatible Scanners: Using scanners that are not compatible with Toyota vehicles.

Error Prevention: An article in Underhood Service Magazine provides tips on avoiding diagnostic errors and ensuring accurate repairs.

12. The Future of Toyota OBD2 Technology

The future of Toyota OBD2 technology includes:

- Enhanced Security: Improved security measures to prevent unauthorized access to vehicle data.

- Wireless Connectivity: Increased use of wireless OBD2 adapters for remote diagnostics.

- Cloud Integration: Integration with cloud-based platforms for data storage and analysis.

- AI-Powered Diagnostics: Use of artificial intelligence to assist in diagnosing complex issues.

Emerging Trends: A report by McKinsey & Company highlights the growing role of connected car technologies and their impact on automotive diagnostics and maintenance.

13. Connecting with OBD2-SCANNER.EDU.VN for Expert Assistance

At OBD2-SCANNER.EDU.VN, we offer expert assistance to help you navigate the complexities of Toyota OBD2 protocols. Whether you’re a seasoned mechanic or a DIY enthusiast, our resources and services are designed to empower you with the knowledge and tools you need.

- Detailed Guides: Access our comprehensive guides on Toyota OBD2 protocols, codes, and troubleshooting techniques.

- Scanner Recommendations: Get personalized recommendations on the best OBD2 scanners for your specific Toyota model.

- Expert Support: Contact our team of experienced technicians for expert advice and support.

14. Step-by-Step Guide to Diagnosing a Toyota with an OBD2 Scanner

Follow these steps for effective Toyota diagnostics:

- Preparation: Gather your OBD2 scanner, vehicle manual, and any relevant repair information.

- Connection: Plug the scanner into the DLC.

- Code Retrieval: Turn on the ignition and retrieve the diagnostic codes.

- Code Interpretation: Research the codes and their possible causes.

- Visual Inspection: Perform a visual inspection of the affected components.

- Testing: Use the scanner to perform component tests and monitor live data.

- Repair: Address the identified issues with appropriate repairs.

- Verification: Clear the codes and verify that the issue is resolved.

Diagnostic Workflow: A flowchart by the Automotive Management Institute (AMI) outlines a systematic approach to vehicle diagnostics, emphasizing the importance of thoroughness and accuracy.

15. Why Choose OBD2-SCANNER.EDU.VN for Your Toyota Diagnostic Needs?

Choosing OBD2-SCANNER.EDU.VN offers several advantages:

- Expertise: Benefit from our team’s extensive knowledge of Toyota vehicles and OBD2 systems.

- Comprehensive Resources: Access a wealth of information, including guides, tutorials, and troubleshooting tips.

- Personalized Support: Receive personalized support to address your specific diagnostic challenges.

- Reliable Recommendations: Get reliable recommendations on OBD2 scanners and diagnostic tools.

16. Understanding Toyota OBD2 Readiness Monitors

Readiness monitors are diagnostic tests that the OBD2 system performs to ensure emission-related components are functioning correctly. Common Toyota readiness monitors include:

- Catalyst Monitor

- Oxygen Sensor Monitor

- Evaporative System Monitor

- EGR System Monitor

Monitor Significance: According to the EPA, readiness monitors play a crucial role in ensuring vehicles comply with emission standards and maintain environmental quality.

17. Clearing Toyota OBD2 Codes: When and How

Clearing OBD2 codes should be done after addressing the underlying issue. Here’s how:

- Address the Problem: Ensure the problem that triggered the code has been resolved.

- Connect the Scanner: Plug the OBD2 scanner into the DLC.

- Clear the Codes: Follow the scanner’s instructions to clear the codes.

- Verify the Repair: Start the engine and monitor the system to ensure the code does not reappear.

Code Clearing Guidelines: An article in Auto Repair Focus advises caution when clearing codes, emphasizing the importance of proper diagnosis and repair verification.

18. How Does Oxygen Sensor Affect Toyota OBD2 Protocol?

The oxygen sensor plays a vital role in Toyota’s OBD2 protocol by monitoring the oxygen levels in the exhaust gases. This data helps the engine control unit (ECU) adjust the air-fuel mixture for optimal combustion and emissions control.

Types of Oxygen Sensors

- Zirconia Oxygen Sensors: These are the most common type, generating a voltage signal based on the difference in oxygen levels between the exhaust gas and ambient air.

- Titania Oxygen Sensors: These sensors use a change in resistance to indicate oxygen levels.

- Wideband Oxygen Sensors (Air-Fuel Ratio Sensors): These provide a more precise measurement of the air-fuel ratio, allowing for finer adjustments to engine performance.

Function of Oxygen Sensors

- Monitoring Air-Fuel Ratio: Oxygen sensors continuously monitor the air-fuel ratio to ensure it is close to the stoichiometric ideal (14.7:1 for gasoline engines).

- Providing Feedback to ECU: The sensor data is sent to the ECU, which adjusts the fuel injection and ignition timing to maintain optimal combustion.

- Detecting Lean or Rich Conditions: Oxygen sensors can detect when the engine is running lean (too much air) or rich (too much fuel), allowing the ECU to correct the mixture.

Impact on OBD2 System

The oxygen sensor’s performance directly affects the OBD2 system. The ECU uses the sensor data to perform various diagnostic tests, including:

- Oxygen Sensor Heater Circuit Test: Ensures the sensor heats up quickly to provide accurate readings.

- Oxygen Sensor Response Test: Verifies that the sensor responds correctly to changes in the air-fuel ratio.

- Fuel Trim Monitoring: Monitors the long-term and short-term fuel trims to detect issues with the fuel system.

Common OBD2 Codes Related to Oxygen Sensors

- P0130-P0167: Oxygen Sensor Circuit Malfunction

- P0171/P0174: System Too Lean (Bank 1/Bank 2)

- P0172/P0175: System Too Rich (Bank 1/Bank 2)

- P0420: Catalyst System Efficiency Below Threshold (Bank 1)

Diagnostic Tips for Oxygen Sensors

- Check for Physical Damage: Inspect the sensor for any signs of damage, such as cracks or corrosion.

- Verify Wiring Connections: Ensure the wiring harness and connectors are in good condition and properly connected.

- Monitor Sensor Data: Use an OBD2 scanner to monitor the sensor’s voltage and response time.

- Perform a Smoke Test: Check for vacuum leaks that can affect the air-fuel ratio.

- Replace if Necessary: If the sensor is faulty, replace it with a high-quality replacement.

19. What Are The Impacts of Catalytic Converter in Toyota OBD2 Protocol?

The catalytic converter is a critical component in Toyota’s emission control system, and it significantly impacts the OBD2 protocol. It reduces harmful pollutants in the exhaust gases.

Function of the Catalytic Converter

- Reducing Harmful Emissions: The catalytic converter uses chemical reactions to convert harmful pollutants, such as hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx), into less harmful substances like carbon dioxide (CO2), water (H2O), and nitrogen (N2).

- Three-Way Catalytic Converter: Most modern vehicles use a three-way catalytic converter, which addresses all three major pollutants simultaneously.

- Monitoring Oxygen Levels: Catalytic converters often have an oxygen sensor located before and after the converter to monitor its efficiency.

Impact on OBD2 System

The catalytic converter’s performance directly affects the OBD2 system. The ECU uses the data from the oxygen sensors to perform various diagnostic tests, including:

- Catalyst Efficiency Monitoring: The ECU compares the oxygen levels before and after the catalytic converter to determine its efficiency.

- Oxygen Storage Capacity Test: This test measures the converter’s ability to store oxygen, which is essential for its proper function.

- Temperature Monitoring: Some systems monitor the temperature of the catalytic converter to prevent overheating and damage.

Common OBD2 Codes Related to Catalytic Converters

- P0420: Catalyst System Efficiency Below Threshold (Bank 1)

- P0421: Warm-Up Catalyst Efficiency Below Threshold (Bank 1)

- P0430: Catalyst System Efficiency Below Threshold (Bank 2)

- P0431: Warm-Up Catalyst Efficiency Below Threshold (Bank 2)

Diagnostic Tips for Catalytic Converters

- Check for Physical Damage: Inspect the converter for any signs of damage, such as dents or corrosion.

- Verify Oxygen Sensor Performance: Ensure the oxygen sensors before and after the converter are functioning correctly.

- Monitor Exhaust Gases: Use an exhaust gas analyzer to measure the levels of HC, CO, and NOx.

- Check for Exhaust Leaks: Look for exhaust leaks that can affect the converter’s efficiency.

- Replace if Necessary: If the converter is faulty, replace it with a high-quality replacement.

20. What is EVAP System And How Does It Relate With Toyota OBD2 Protocol?

The Evaporative Emission Control (EVAP) system is designed to prevent fuel vapors from escaping into the atmosphere. It captures, stores, and then purges these vapors into the engine to be burned during combustion.

Components of the EVAP System

- Fuel Tank: The fuel tank is sealed to prevent vapors from escaping.

- Charcoal Canister: This canister contains activated charcoal, which absorbs and stores fuel vapors.

- Purge Valve: This valve controls the flow of fuel vapors from the charcoal canister to the engine.

- Vent Valve: This valve allows fresh air to enter the EVAP system.

- Pressure Sensor: This sensor monitors the pressure in the EVAP system.

Function of the EVAP System

- Capturing Fuel Vapors: The EVAP system captures fuel vapors from the fuel tank and stores them in the charcoal canister.

- Purging Fuel Vapors: When the engine is running, the purge valve opens, allowing the engine to draw fuel vapors from the charcoal canister.

- Monitoring System Integrity: The EVAP system monitors its integrity to detect leaks or malfunctions.

Impact on OBD2 System

The EVAP system’s performance directly affects the OBD2 system. The ECU uses various diagnostic tests to monitor the EVAP system, including:

- EVAP Leak Test: This test checks for leaks in the EVAP system.

- Purge Flow Test: This test verifies that the purge valve is functioning correctly.

- Vent Valve Test: This test ensures the vent valve is operating as intended.

Common OBD2 Codes Related to the EVAP System

- P0440: Evaporative Emission Control System Malfunction

- P0441: Evaporative Emission Control System Incorrect Purge Flow

- P0442: Evaporative Emission Control System Leak Detected (Small Leak)

- P0446: Evaporative Emission Control System Vent Control Circuit Malfunction

Diagnostic Tips for the EVAP System

- Check for Fuel Cap Issues: Ensure the fuel cap is properly tightened and in good condition.

- Inspect Hoses and Connections: Look for cracks, leaks, or loose connections in the EVAP system hoses.

- Test the Purge Valve: Verify that the purge valve is opening and closing correctly.

- Check the Charcoal Canister: Inspect the charcoal canister for damage or saturation.

- Perform a Smoke Test: Use a smoke machine to detect leaks in the EVAP system.

21. What Role Does MAF Sensor Play In Toyota OBD2 Protocol?

The Mass Airflow (MAF) sensor is critical to Toyota’s OBD2 protocol as it measures the amount of air entering the engine. This data is used by the ECU to calculate the correct amount of fuel to inject for optimal combustion.

Types of MAF Sensors

- Hot-Wire MAF Sensors: These sensors use a heated wire to measure the mass of air flowing through the sensor.

- Hot-Film MAF Sensors: These sensors use a heated film to measure the mass of air.

- Vane Meter MAF Sensors: These sensors use a mechanical vane to measure the volume of air.

Function of the MAF Sensor

- Measuring Airflow: The MAF sensor measures the mass of air entering the engine.

- Providing Data to ECU: The sensor data is sent to the ECU, which uses it to calculate the correct amount of fuel to inject.

- Adjusting Fuel Injection: The ECU adjusts the fuel injection based on the airflow to maintain the optimal air-fuel ratio.

Impact on OBD2 System

The MAF sensor’s performance directly affects the OBD2 system. The ECU uses the sensor data to perform various diagnostic tests, including:

- MAF Sensor Circuit Test: Ensures the sensor is functioning correctly.

- Airflow Monitoring: Monitors the airflow to detect issues with the intake system.

- Fuel Trim Monitoring: Monitors the long-term and short-term fuel trims to detect issues with the fuel system.

Common OBD2 Codes Related to the MAF Sensor

- P0100: Mass or Volume Air Flow Circuit Malfunction

- P0101: Mass or Volume Air Flow Circuit Range/Performance Problem

- P0102: Mass or Volume Air Flow Circuit Low Input

- P0103: Mass or Volume Air Flow Circuit High Input

Diagnostic Tips for the MAF Sensor

- Check for Physical Damage: Inspect the sensor for any signs of damage, such as cracks or corrosion.

- Verify Wiring Connections: Ensure the wiring harness and connectors are in good condition and properly connected.

- Clean the Sensor: Use a MAF sensor cleaner to remove dirt and debris from the sensor.

- Monitor Sensor Data: Use an OBD2 scanner to monitor the sensor’s readings.

- Replace if Necessary: If the sensor is faulty, replace it with a high-quality replacement.

22. What Role Does Crankshaft Position Sensor Play in Toyota OBD2 Protocol?

The Crankshaft Position (CKP) sensor is a critical component in Toyota’s OBD2 protocol, as it monitors the position and speed of the crankshaft. This data is essential for controlling ignition timing, fuel injection, and detecting misfires.

Types of Crankshaft Position Sensors

- Magnetic Inductive Sensors: These sensors generate an AC voltage signal as the crankshaft rotates, which is used to determine the position and speed of the crankshaft.

- Hall Effect Sensors: These sensors use a magnetic field and a semiconductor to generate a digital signal that indicates the position of the crankshaft.

Function of the Crankshaft Position Sensor

- Monitoring Crankshaft Position: The CKP sensor provides real-time data on the position of the crankshaft.

- Determining Engine Speed: The sensor also measures the speed at which the crankshaft is rotating.

- Providing Data to ECU: The sensor data is sent to the ECU, which uses it to control ignition timing and fuel injection.

Impact on OBD2 System

The CKP sensor’s performance directly impacts the OBD2 system. The ECU uses the sensor data to perform various diagnostic tests, including:

- CKP Sensor Circuit Test: Ensures the sensor is functioning correctly.

- Misfire Detection: The sensor helps detect misfires by monitoring the speed variations of the crankshaft.

- Timing Control: The CKP sensor is critical for proper ignition and fuel injection timing.

Common OBD2 Codes Related to the Crankshaft Position Sensor

- P0335: Crankshaft Position Sensor A Circuit Malfunction

- P0336: Crankshaft Position Sensor A Circuit Range/Performance

- P0337: Crankshaft Position Sensor A Circuit Low Input

- P0338: Crankshaft Position Sensor A Circuit High Input

Diagnostic Tips for the Crankshaft Position Sensor

- Check for Physical Damage: Inspect the sensor for any signs of damage, such as cracks or corrosion.

- Verify Wiring Connections: Ensure the wiring harness and connectors are in good condition and properly connected.

- Check Sensor Air Gap: Ensure the correct air gap between the sensor and the crankshaft reluctor wheel.

- Monitor Sensor Data: Use an OBD2 scanner to monitor the sensor’s signal.

- Replace if Necessary: If the sensor is faulty, replace it with a high-quality replacement.

23. Frequently Asked Questions (FAQs) About Toyota OBD2 Protocols

Q: What is an OBD2 scanner?

An OBD2 scanner is a diagnostic tool used to read and interpret data from a vehicle’s onboard computer system. It helps identify potential issues and troubleshoot problems.

Q: How do I read Toyota OBD2 codes?

Connect the scanner to the DLC, turn on the ignition, and follow the scanner’s instructions to retrieve the codes.

Q: What are common Toyota OBD2 error codes?

Common codes include P0171 (System Too Lean), P0300 (Misfire Detected), and P0420 (Catalyst System Efficiency Below Threshold).

Q: Can I use any OBD2 scanner on my Toyota?

Most OBD2 scanners are compatible with Toyota vehicles, but it’s essential to ensure the scanner supports the correct protocols and features.

Q: How do I clear OBD2 codes on my Toyota?

After addressing the issue, connect the scanner to the DLC, turn on the ignition, and follow the scanner’s instructions to clear the codes.

Q: What does “readiness monitor” mean in OBD2?

Readiness monitors are diagnostic tests that the OBD2 system performs to ensure emission-related components are functioning correctly.

Q: Where is the DLC located in my Toyota?

The DLC is typically located under the dashboard on the driver’s side.

Q: What is a Toyota-specific PID?

Toyota-specific PIDs are codes used to request proprietary data from the vehicle’s ECU, not available through generic OBD2 codes.

Q: How can OBD2-SCANNER.EDU.VN help with Toyota diagnostics?

OBD2-SCANNER.EDU.VN offers detailed guides, scanner recommendations, and expert support to help you navigate Toyota OBD2 protocols.

Q: Is it safe to drive with an OBD2 code active?

It depends on the code. Some codes indicate minor issues, while others can signal severe problems. It’s best to diagnose and address the issue as soon as possible.

Q: What if my OBD2 scanner can’t connect to my Toyota?

Ensure the scanner is compatible with your Toyota model, check the DLC for damage, and verify the scanner’s power supply.

Q: How often should I scan my Toyota for OBD2 codes?

You should scan your Toyota whenever you notice unusual symptoms, such as engine misfires, decreased fuel efficiency, or warning lights on the dashboard. Regularly scanning your vehicle can help you catch minor issues before they become major problems.

Conclusion

Understanding the Toyota OBD2 protocol is essential for maintaining your vehicle’s health and performance. With the right knowledge and tools, you can diagnose and address issues efficiently, saving time and money. At OBD2-SCANNER.EDU.VN, we are committed to providing you with the resources and support you need to master Toyota OBD2 diagnostics.

Ready to take control of your Toyota’s diagnostics? Contact us today at 123 Main Street, Los Angeles, CA 90001, United States, or call us on Whatsapp at +1 (641) 206-8880. Visit our website at OBD2-SCANNER.EDU.VN for more information and expert assistance. Let us help you keep your Toyota running smoothly and efficiently.